Non-continuous outer trapezoid longitudinal rib tube

A discontinuous, longitudinal rib technology, applied in the field of discontinuous outer trapezoidal longitudinal rib tubes, can solve the problems of low manufacturing cost, strong heat transfer coefficient, large heat transfer area, etc., and achieve compact structure, high heat transfer coefficient, large ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

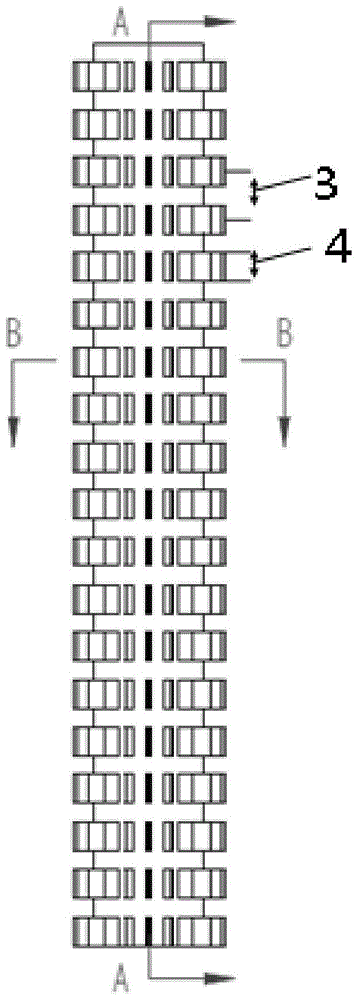

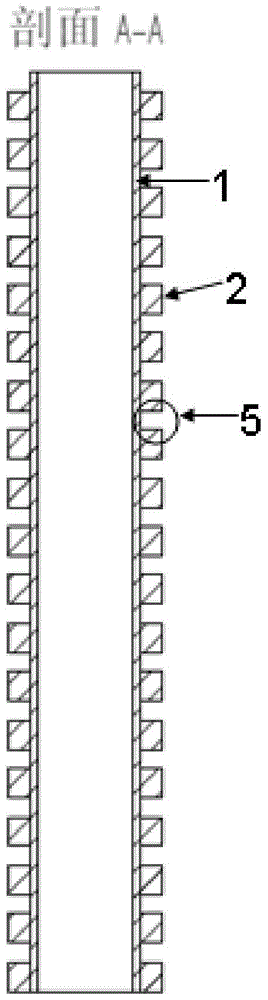

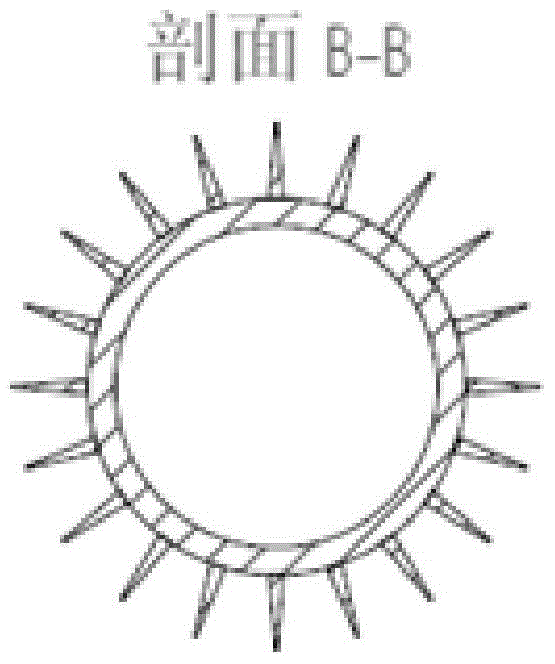

[0013] see figure 1 and Figure 4 , the present invention consists of a base pipe (1) and a trapezoidal cross-section longitudinal rib (2), a plurality of trapezoidal longitudinal ribs are evenly distributed in the peripheral direction of the base pipe, and mechanically formed with the base pipe, in the longitudinal direction of the base pipe, a plurality of discontinuous trapezoidal The longitudinal ribs are arranged in parallel or staggered rows, the structure and size of the trapezoidal longitudinal ribs outside the base pipe are consistent, and the interval length (5) between the upper and lower longitudinal ribs outside the base pipe is consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com