An inner tube spinning type purification and thermal conduction reinforced tooth shape twisting belt

A heat transfer enhancement and twisted belt technology, applied in the field of toothed twisted belts, can solve the problem of small torque of helical twisting, and achieve the effect of high convective heat transfer coefficient and enhanced convective heat transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

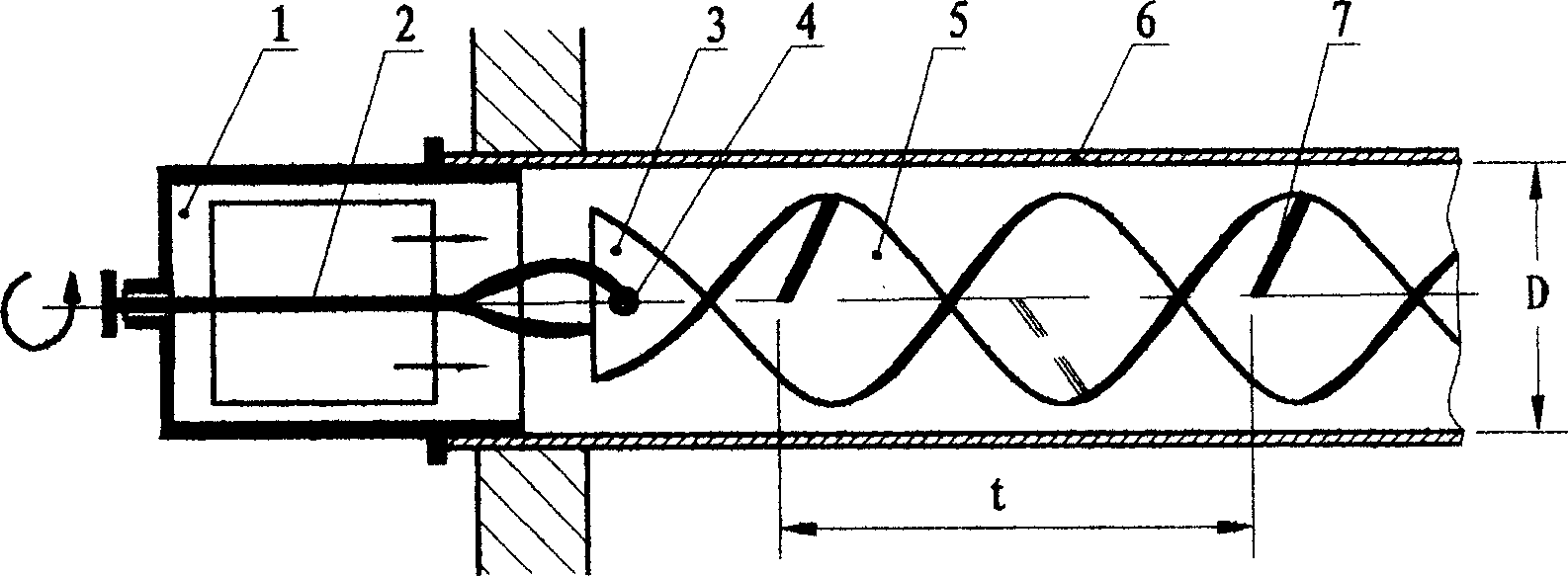

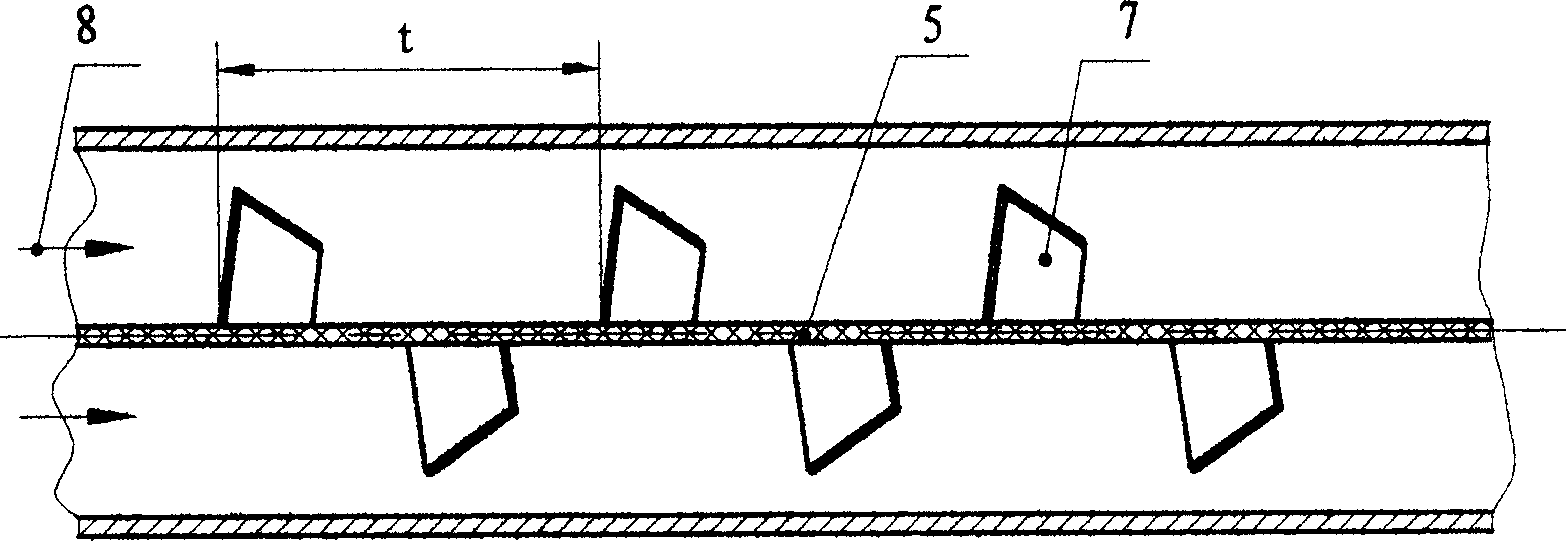

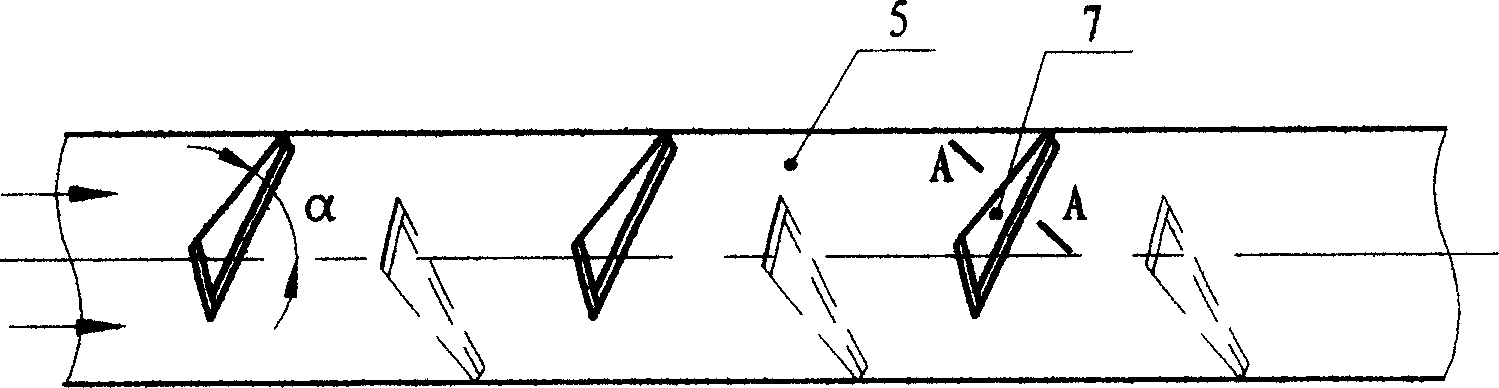

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] In the figure 1. Nozzle fixing device 2. Rotating shaft 3. Helical twisted belt head 4. Connection hole 5. Helical twisted belt 6. Heat transfer tube 7. Strengthening teeth 8. Flowing liquid in the tube 9. Reaction force 10. Additional rotational power moment

[0014] A tooth-shaped twisted belt with self-rotating cleaning and heat transfer enhancement in the tube, made of engineering plastics, with a width slightly smaller than the diameter of the heat transfer tube 6, a length that is basically the same as that of the heat transfer tube 6, and a connecting hole 4 The helical sheet-shaped twisted ribbon 5 is placed in the heat transfer tube 6 . The rotating shaft 2 is connected with the connecting hole 4 of the head 3 of the spiral twisted band, the other end of the rotating shaft 2 is axially fixed on the spout fixing device 1, and the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com