Phosphor copper ball with grooves at surface and preparation method thereof

A technology of phosphor bronze balls and phosphor bronze, which is applied in the field of phosphor bronze balls and its preparation, can solve the problems of larger size of phosphor bronze balls, waste of copper ions, fixed surface area, etc., and achieve reduced electroplating time, high utilization rate, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

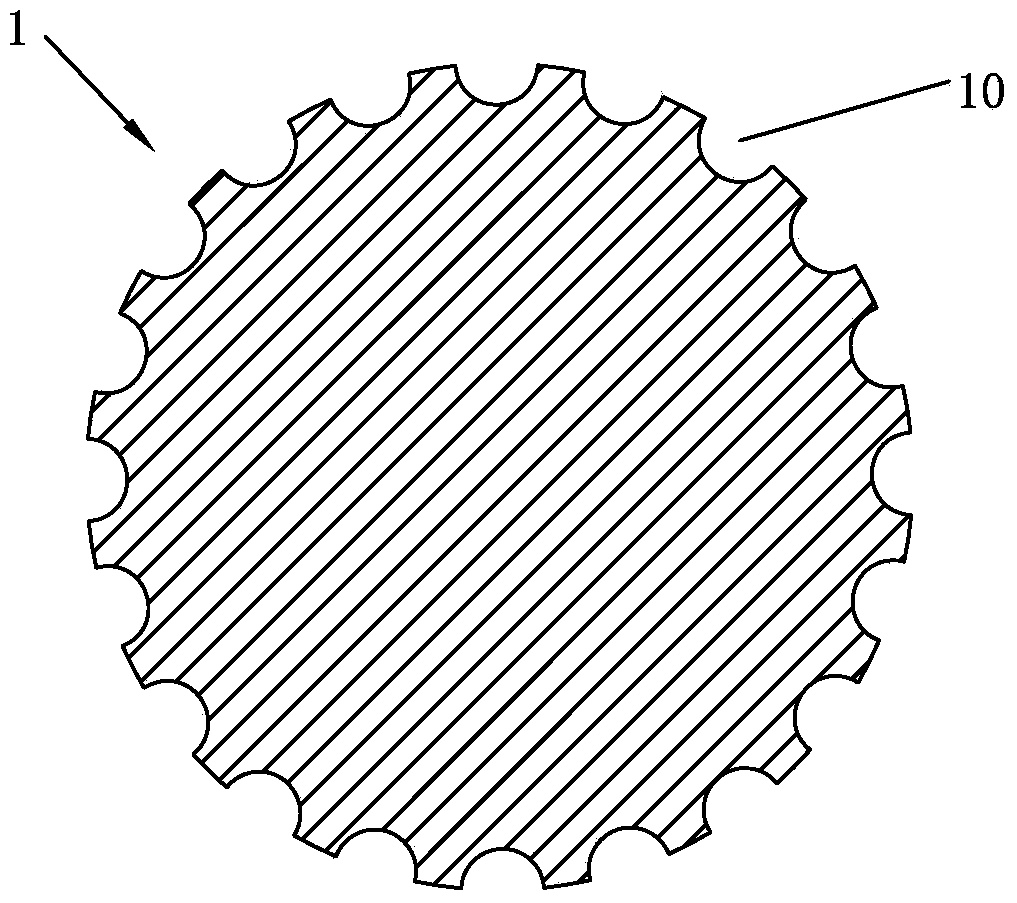

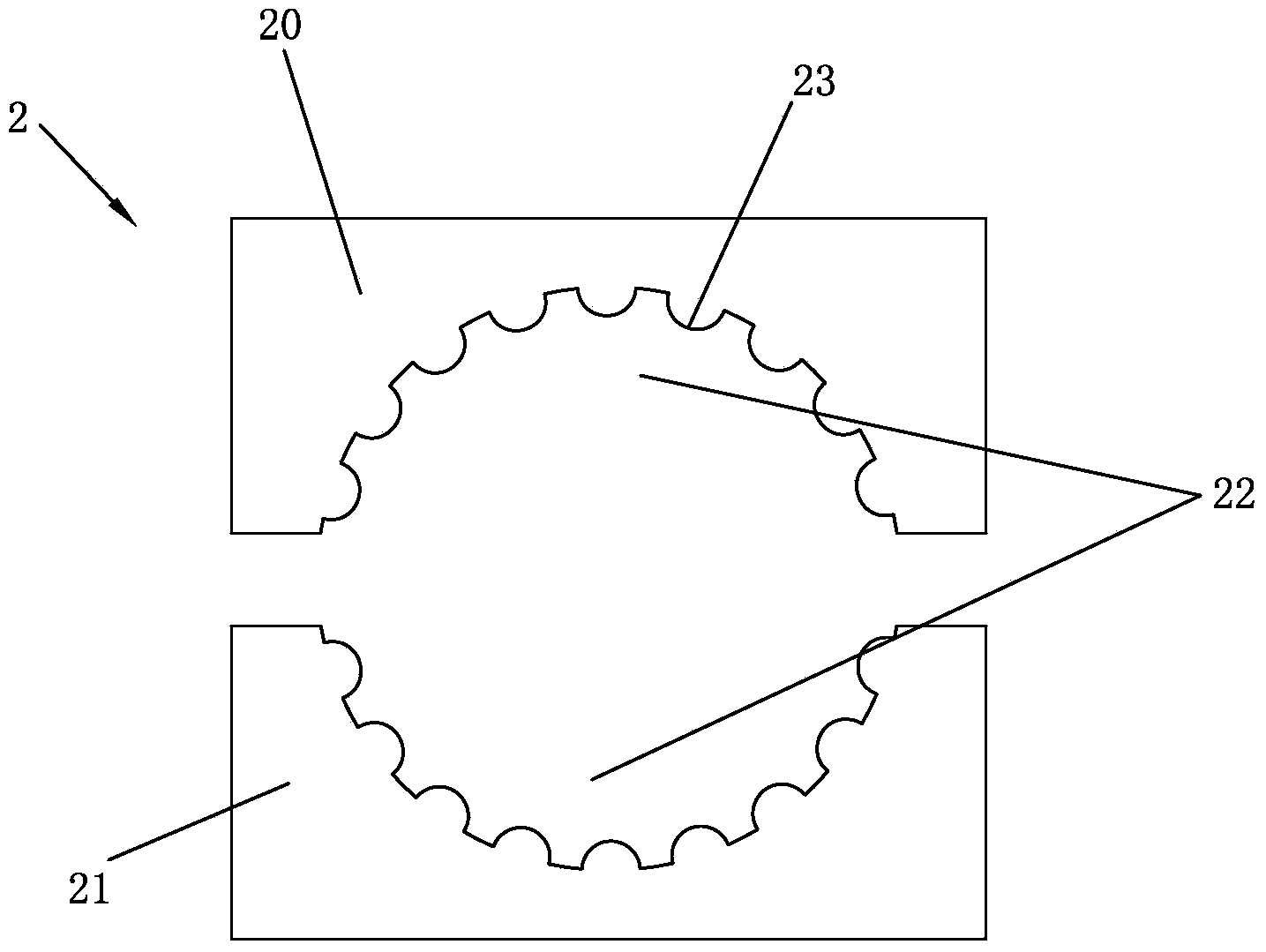

[0025] The surface of this embodiment has phosphor bronze balls with grooves, such as figure 1 As shown, it includes a phosphor bronze ball body 1 and grooves 10 arranged at intervals on the surface of the phosphor bronze ball body 1, the grooves 10 are evenly distributed on the entire surface of the phosphor bronze ball body 1, the shape is hemispherical, and all the grooves The centers of 10 are all on the same spherical surface.

[0026] The preparation method of the above-mentioned phosphor bronze ball with grooves on the surface is as follows:

[0027] The copper raw material is electrolytic copper or bright copper with a copper content of 99.99%, and the phosphorus raw material is a phosphor-bronze master alloy with a phosphorus content of 5-15% by mass, which specifically includes the following steps:

[0028] (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com