Hydrogenated titanium dioxide nanotube/nano-particle composite photocatalytic material and preparation method thereof

A technology of hydrogenating titanium dioxide and nanoparticles, which is applied in the field of photocatalytic materials, can solve the problems of low visible light catalytic activity, etc., and achieve the effects of high photocatalytic activity, simple and easy preparation method, and high external surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

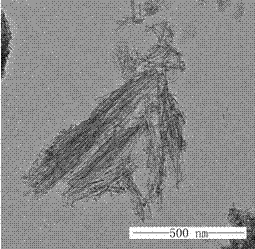

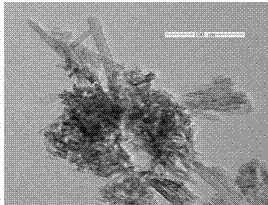

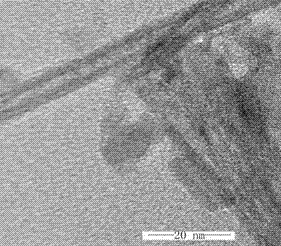

Image

Examples

Embodiment 1

[0026] Add 1.0 g of titanium dioxide nanoparticles into 80 mL of 10 M NaOH solution, ultrasonically disperse for 30 min, and then stir for 3 h in the dark. Then put it in a hydrothermal reaction kettle for hydrothermal reaction at 120°C for 24 hours. After cooling to room temperature, wash it with deionized water to neutrality, then wash it with 0.02M HCl solution until the pH value is 3, and then wash it with deionized water. Wash with water until neutral, and dry the solid product in a drying oven at 80°C. The dried solid was ground with an agate mortar and placed in a quartz boat in a quartz tube furnace, then the quartz boat was placed in the quartz tube, and a mixed gas of hydrogen / nitrogen was continuously introduced at a flow rate of 300 mL / min (mixed In gas, H 2 The volume fraction is 10%, N 2 The volume fraction is 90%), the tube furnace was raised to 500 °C at a rate of 5 °C / min, and calcined for 3 h. Stop feeding the mixed gas after the tube furnace is cooled to ...

Embodiment 2

[0028] Add 0.5g of titanium dioxide into 60mL of 9M NaOH solution for ultrasonic dispersion for 60min, and stir in the dark for 4h; put it in a hydrothermal reaction kettle for hydrothermal reaction at 170°C for 24h, after cooling to room temperature, wash with deionized water to medium Then wash with 0.03M HCl solution until the pH value is 3, then wash with deionized water until neutral, and dry the solid product in a drying oven at 80°C. The dried solid was ground with an agate mortar and placed in a quartz boat in a quartz tube furnace, then the quartz boat was placed in the quartz tube, and a mixed gas of hydrogen / nitrogen was continuously introduced at a flow rate of 200 mL / min (mixed In gas, H 2 The volume fraction is 20%, N 2 The volume fraction is 80%), and the tube furnace is raised to 450°C at a rate of 10°C / min, calcined for 3 hours, and the mixed gas is stopped after the tube furnace is cooled to 100°C, and the product is hydrogenated titanium dioxide nanometer ...

Embodiment 3

[0030] Add 1.5g of titanium dioxide into 100mL of 10M NaOH solution for ultrasonic dispersion for 45min, and stir in the dark for 5h; place it in a hydrothermal reaction kettle for hydrothermal reaction at 150°C for 48h, cool to room temperature, and wash with deionized water to medium After washing with 0.05M HCl solution until the pH value is 3, and then washing with deionized water until neutral, the solid product is dried in a drying oven at 100°C. The dried solid was ground with an agate mortar and placed in a quartz boat in a quartz tube furnace, then the quartz boat was placed in the quartz tube, and a mixed gas of hydrogen / nitrogen was continuously introduced at a flow rate of 180 mL / min (mixed gas Medium, H 2 The volume fraction is 10%, N 2 The volume fraction is 90%), and the tube furnace is raised to 400°C at a rate of 5°C / min, calcined for 6h, and the mixed gas is stopped after the tube furnace is cooled to 100°C, and the product is hydrogenated titanium dioxide n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com