Method for checking anti-frost heaving damage of slope concrete lining layer of water conveyance canal in winter

A technology of concrete and lining layer, applied in the direction of calculation, special data processing application, instrument, etc., can solve the problem of not taking into account the influence of two-way freezing and deformation interaction, and achieve the effect of safe and reliable operation and engineering benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

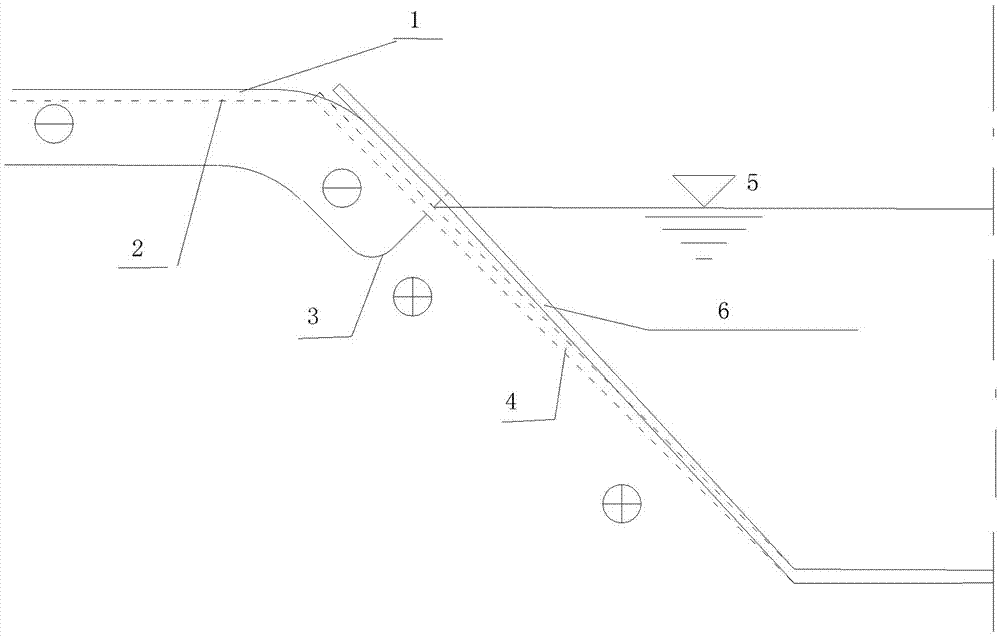

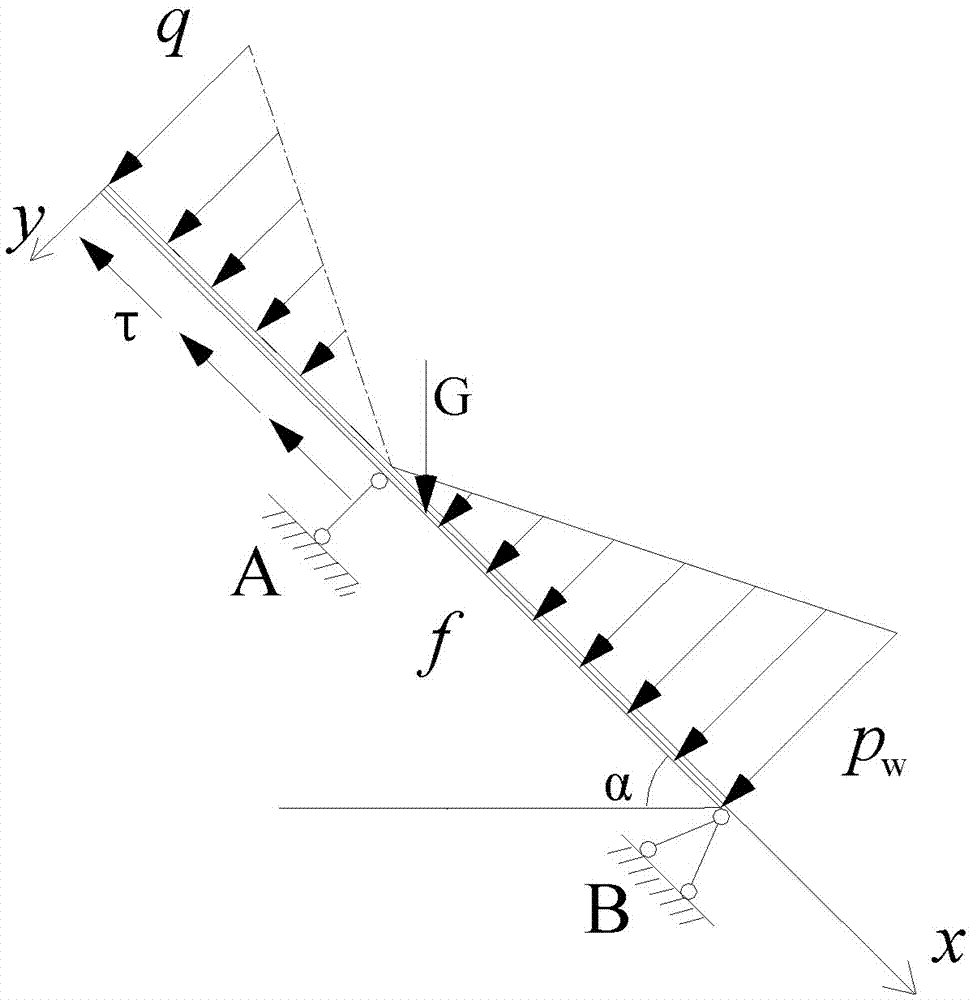

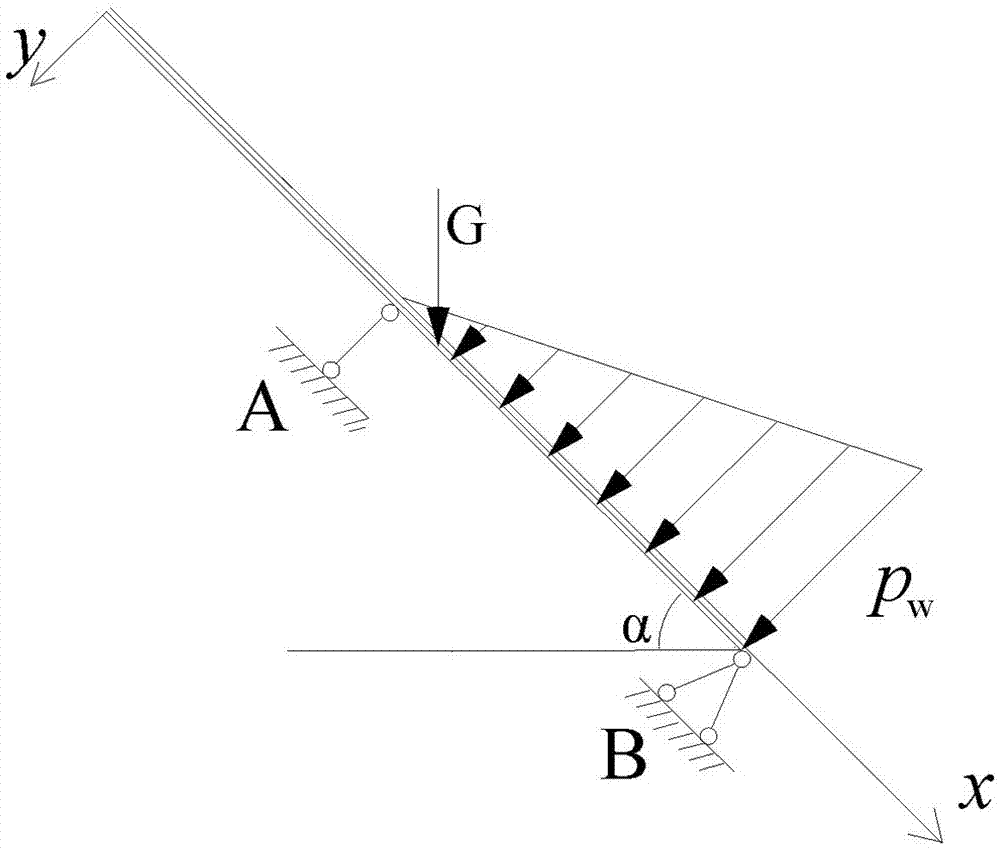

[0030] The invention proposes a method for checking and calculating the anti-frost heave damage of the concrete lining layer of the side slope of the aqueduct in winter. For the concrete lining layer of the side slope of the canal without horizontal joints, the concrete lining layer of the side slope of the canal is regarded as the fixed hinge support at the foot of the slope. The water level surface is the component of the movable hinge support, and the mechanical model of the frost heave damage check calculation of the concrete lining layer of the canal slope is established, and the stress generated by the transverse bending action of the component or the combined action of tension and bending is compared with the axial tensile strength of the concrete To judge whether the slope concrete lining can resist the damage caused by frost heave.

Embodiment 2

[0032] The anti-frost heave damage checking method of the concrete lining layer of the aqueduct slope in winter described in this embodiment is different from that of embodiment 1 in that: the mechanical model required in embodiment 1 is established in order to carry out the frost heave resistance of the concrete lining layer damage check,

[0033] When the slope concrete lining layer can restrain the frost heaving deformation of the canal foundation soil, the deformation of the two is coordinated, and the slope concrete lining layer and the permafrost are frozen as one, at this time the direction of the frost heave force is consistent with the normal direction of the slope surface The normal frost heave force and the tangential frost heave force directed to the top of the slope only act on the slope concrete lining in the area above the water level, and both are based on the value at the water level of the canal being zero, and the value at the top of the canal The slope is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com