Heat-sealing easy-to-repeatedly tear PE film and preparation method thereof

A hot-melt adhesive and intermediate layer technology, which is applied in chemical instruments and methods, adhesive additives, layered products, etc., can solve the problems of difficult sealing and preservation of products, heat-sealed edges that cannot be peeled off, etc., and achieve good impact resistance Intensity, high softness, smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

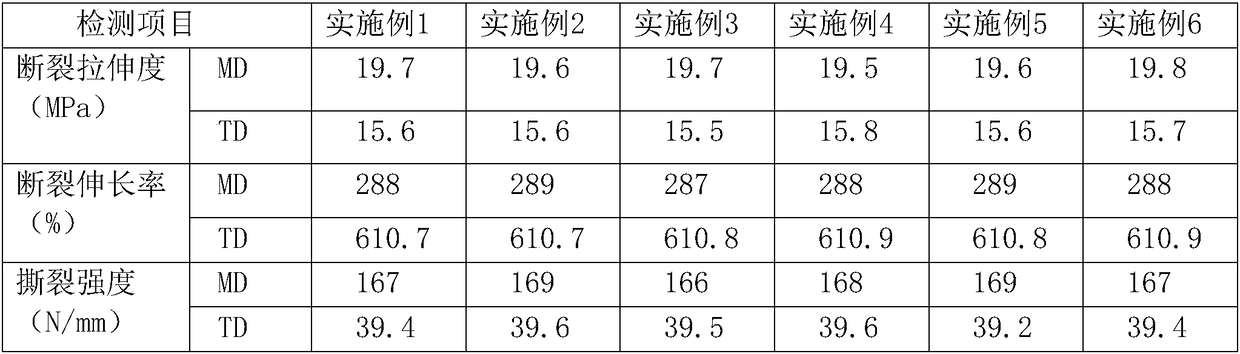

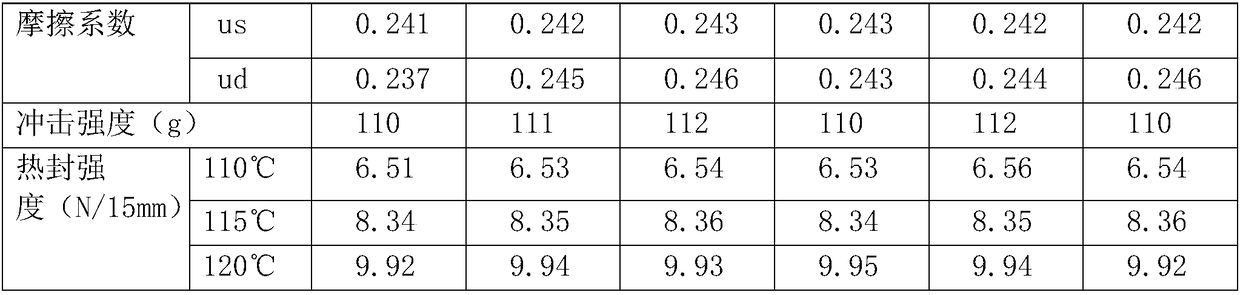

Examples

Embodiment 1

[0032] Embodiment 1: A heat-sealed PE film that is easy to peel off repeatedly, including an inner layer, an intermediate layer, and a surface layer that are stacked in sequence, and the inner layer includes the following components by weight: 1.5 parts has a melt index of 2 g / 10 min and a density of 0.926g / cm 3 LDPE, 3 parts melt index is 2g / 10min, density is 0.921g / cm 3 LLDPE, 3 parts melt index is 2g / 10min, density is 0.905g / cm 3 Metallocene LLPDE and 0.08 parts of PPA masterbatch, the middle layer includes No. 1 material of the middle layer and No. 2 material of the middle layer, and the No. 1 material of the middle layer includes 10 parts by weight, the melt index is 4g / 10min, and the density is 0.920g / cm 3LDPE, the middle layer No. 2 material includes 3 parts by weight of styrene-ethylene-styrene block copolymer, 1.5 parts of rosin resin, 1.5 parts of acrylonitrile-butadiene-styrene copolymer, the surface layer Including the following components by weight: 1.5 parts h...

Embodiment 2

[0041] Embodiment 2: A heat-sealed PE film that is easy to peel off repeatedly, including an inner layer, an intermediate layer and a surface layer that are stacked in sequence, and the inner layer includes the following components by weight: 1.8 parts have a melt index of 2g / 10min and a density of 0.926g / cm 3 LDPE, 3.6 parts have a melt index of 2g / 10min and a density of 0.921g / cm 3 The LLDPE, 3.6 parts have a melt index of 2g / 10min and a density of 0.905g / cm 3 Metallocene LLPDE and 0.08 parts of PPA masterbatch, the middle layer includes No. 1 material of the middle layer and No. 2 material of the middle layer, and the No. 1 material of the middle layer includes 10 parts by weight, the melt index is 4g / 10min, and the density is 0.920g / cm 3 LDPE, the middle layer No. 2 material includes 4 parts by weight of styrene-ethylene-styrene block copolymer, 2 parts of rosin resin, 2 parts of acrylonitrile-butadiene-styrene copolymer, the surface layer Including the following compon...

Embodiment 3

[0050] Embodiment 3: A heat-sealed PE film that is easy to peel off repeatedly, including an inner layer, an intermediate layer, and a surface layer that are stacked in sequence, and the inner layer includes the following components by weight: 2 parts have a melt index of 2g / 10min and a density of 0.926g / cm 3 LDPE, 4 parts with a melt index of 2g / 10min and a density of 0.921g / cm 3 LLDPE, 4 parts have a melt index of 2g / 10min and a density of 0.905g / cm 3 Metallocene LLPDE and 0.08 parts of PPA masterbatch, the middle layer includes No. 1 material of the middle layer and No. 2 material of the middle layer, and the No. 1 material of the middle layer includes 10 parts by weight, the melt index is 4g / 10min, and the density is 0.920g / cm 3 LDPE, the middle layer No. 2 material includes 4.5 parts by weight of styrene-ethylene-styrene block copolymer, 2.25 parts of rosin resin, 2.25 parts of acrylonitrile-butadiene-styrene copolymer, the surface layer Including the following compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com