Printing ink for graphic printing of medical packaging bag

A packaging bag, graphic technology, applied in the field of processing and production of medical supplies, can solve the problems of difficult removal, troublesome processing, production efficiency, etc., achieve good adhesion performance, fast drying speed, prevent floating color and hair loss flower effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

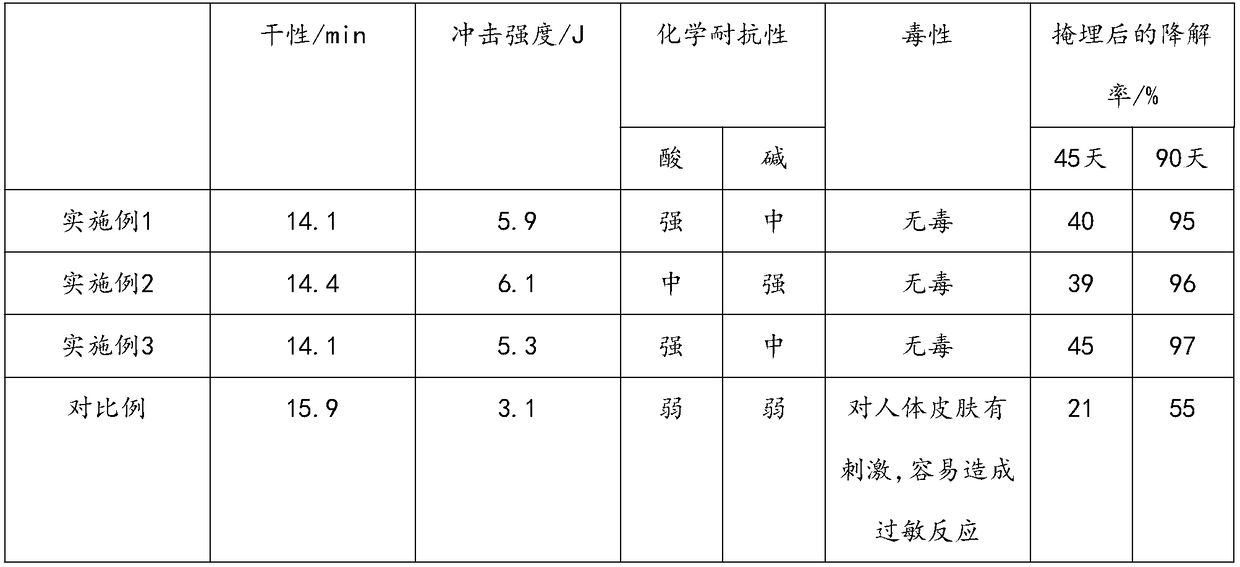

Examples

Embodiment 1

[0030] An ink for graphic printing of medical packaging bags is characterized in that: it is made of the following materials by weight,

[0031] 4 parts of pigment, 5 parts of dimethyl silicone oil, 3 parts of ethyl acetate, 3 parts of polytetrafluoroethylene wax powder, 3 parts of dipentaerythritol hexaacrylate, 2 parts of silane coupling agent KH-5502, 1 part of hydroxyethylidene diphosphonic acid 1 part, 1 part of disodium hydrogen phosphate, 3 parts of modified starch, 1 part of 4010 wetting and dispersing agent, 2 parts of RQT-P-1 plasticizer, 8 parts of auxiliary agent, 2 parts of auxiliary agent, 60 parts of deionized water;

[0032] The pigment is one of quinacridone, phthalocyanine, 3,4,9,10-perylenetetracarboximide, and triarylmethane dyes;

[0033] The preparation method of the modified starch is as follows: configure 100-120 parts by weight of starch into an aqueous starch solution, gelatinize at 80-90°C, add 3-6 parts by weight of azobisisobutyronitrile, and add 6...

Embodiment 2

[0045] An ink for graphic printing of medical packaging bags is characterized in that: it is made of the following materials by weight,

[0046] 9 parts of pigment, 9 parts of dimethyl silicone oil, 8 parts of ethyl acetate, 8 parts of polytetrafluoroethylene wax powder, 7 parts of dipentaerythritol hexaacrylate, 7 parts of silane coupling agent KH-5507, 4 parts of hydroxyethylidene diphosphonic acid 4 parts, disodium hydrogen phosphate 4 parts, modified starch 9 parts, 4010 wetting and dispersing agent 4 parts, RQT-P-1 plasticizer 6 parts, auxiliary agent 14 parts, auxiliary agent 6 parts, deionized water 70 parts;

[0047] The pigment is one of quinacridone, phthalocyanine, 3,4,9,10-perylenetetracarboximide, and triarylmethane dyes;

[0048] The preparation method of the modified starch is as follows: configure 100-120 parts by weight of starch into an aqueous starch solution, gelatinize at 80-90°C, add 3-6 parts by weight of azobisisobutyronitrile, and add 6-6 parts by weig...

Embodiment 3

[0060] An ink for graphic printing of medical packaging bags is characterized in that: it is made of the following materials by weight,

[0061] 6 parts of pigment, 6 parts of dimethyl silicone oil, 7 parts of ethyl acetate, 5 parts of polytetrafluoroethylene wax powder, 5 parts of dipentaerythritol hexaacrylate, 6 parts of silane coupling agent KH-5506, 2 parts of hydroxyethylidene diphosphonic acid 3 parts, 3 parts of disodium hydrogen phosphate, 5 parts of modified starch, 3 parts of 4010 wetting and dispersing agent, 4 parts of RQT-P-1 plasticizer, 10 parts of auxiliary agent, 5 parts of auxiliary agent, 66 parts of deionized water;

[0062] The pigment is one of quinacridone, phthalocyanine, 3,4,9,10-perylenetetracarboximide, and triarylmethane dyes;

[0063] The preparation method of the modified starch is as follows: configure 100-120 parts by weight of starch into an aqueous starch solution, gelatinize at 80-90°C, add 3-6 parts by weight of azobisisobutyronitrile, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com