Fluorine-silicon-epoxy-modified aqueous acrylate emulsion ink special for PVC film and preparation method of ink

A water-based acrylate, PVC film technology, applied in the field of printing ink, can solve the problems of not meeting the high-speed printing process of PVC film, poor wetting effect of PVC film, poor wetting effect of water-based ink, etc. Accelerates surface drying and improves adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1) Preparation of fluorine-silicon-epoxy modified waterborne acrylate emulsion

[0054] (1) Nuclear pre-emulsion: Weigh 0.08g of sodium lauryl sulfate, 0.1g of alkylphenol polyoxyethylene ether, 2.5g of deionized water, mix well, add 2g of N-methylol Acrylamide, 3g of hydroxyethyl methacrylate, 4g of methyl methacrylate and 8g of ethyl methacrylate were mixed and then added dropwise. Stirring while adding dropwise, control the dropwise addition within 10 minutes, and finally at 200r / Stir at a stirring speed of 1 min for 20 min to obtain a nuclear pre-emulsion;

[0055] Shell pre-emulsion: weigh 0.4g of sodium lauryl sulfate, 0.6g of alkylphenol polyoxyethylene ether, 10g of deionized water, mix well, add 2g of vinyl diethoxysilane, 2.5 g of hexafluorobutyl acrylate, 4g of epoxy resin E12, 6g of methyl methacrylate, 8g of ethyl methacrylate, 14g of methyl acrylate, add dropwise after mixing, stirring while adding dropwise, control After the dripping in 10 minutes, stir for...

Embodiment 2

[0065] 1) Preparation of fluorine-silicon-epoxy modified waterborne acrylate emulsion

[0066] (1) Nuclear pre-emulsion: Weigh 0.1g of sodium dodecylbenzene sulfonate, 0.2g of alkylphenol polyoxyethylene ether, 4g of deionized water, and mix well, then add 2.2g of N-hydroxyl Ethyl acrylamide, 2.5g of hydroxypropyl methacrylate, 6g of methyl methacrylate and 6g of butyl methacrylate were mixed and added dropwise, while stirring while adding dropwise, the addition was controlled within 10 minutes, and finally Stir at a stirring speed of 200r / min for 20min to obtain a core pre-emulsion; shell pre-emulsion: weigh 0.5g sodium dodecylbenzene sulfonate, 0.7g alkylphenol polyoxyethylene ether, 10g deionized Water, mix well, mix 3g vinyl triethoxy silane, 3g dodecafluoroheptyl methacrylate, 2g epoxy resin E44, 10g methyl methacrylate, 6g butyl methacrylate , 16g of ethyl acrylate, added dropwise after mixing, stirring while adding dropwise, control the dropwise addition at 10min, and fin...

Embodiment 3

[0074] 1) Preparation of fluorine-silicon-epoxy modified waterborne acrylate emulsion

[0075] (1) Nuclear pre-emulsion: Weigh 0.15g of sodium dodecylbenzene sulfonate, 0.2g of lauric acid monoglyceride, 5g of deionized water, mix well, then add 3g of N-butoxypropylene Amide, 3g of methacrylic acid, 8g of methyl methacrylate and 6g of styrene were mixed and added dropwise. Stir while adding dropwise. Control the dropwise addition at 10min, and finally stir for 20min at a stirring speed of 200r / min Obtain the core pre-emulsion; shell pre-emulsion: Weigh 0.6g of sodium dodecylbenzene sulfonate, 0.8g of lauric acid monoglyceride, 10g of deionized water, mix well, add 3g of vinyl tri Isopropoxysilane, 5g of 2-perfluorooctyl ethyl methacrylate, 2g of epoxy resin E51, 10g of methyl methacrylate, 10g of styrene, 18g of butyl acrylate, drop after mixing Add it, and stir while adding dropwise. Control the dropwise addition within 10 minutes, and finally stir for 20 minutes at a stirring ...

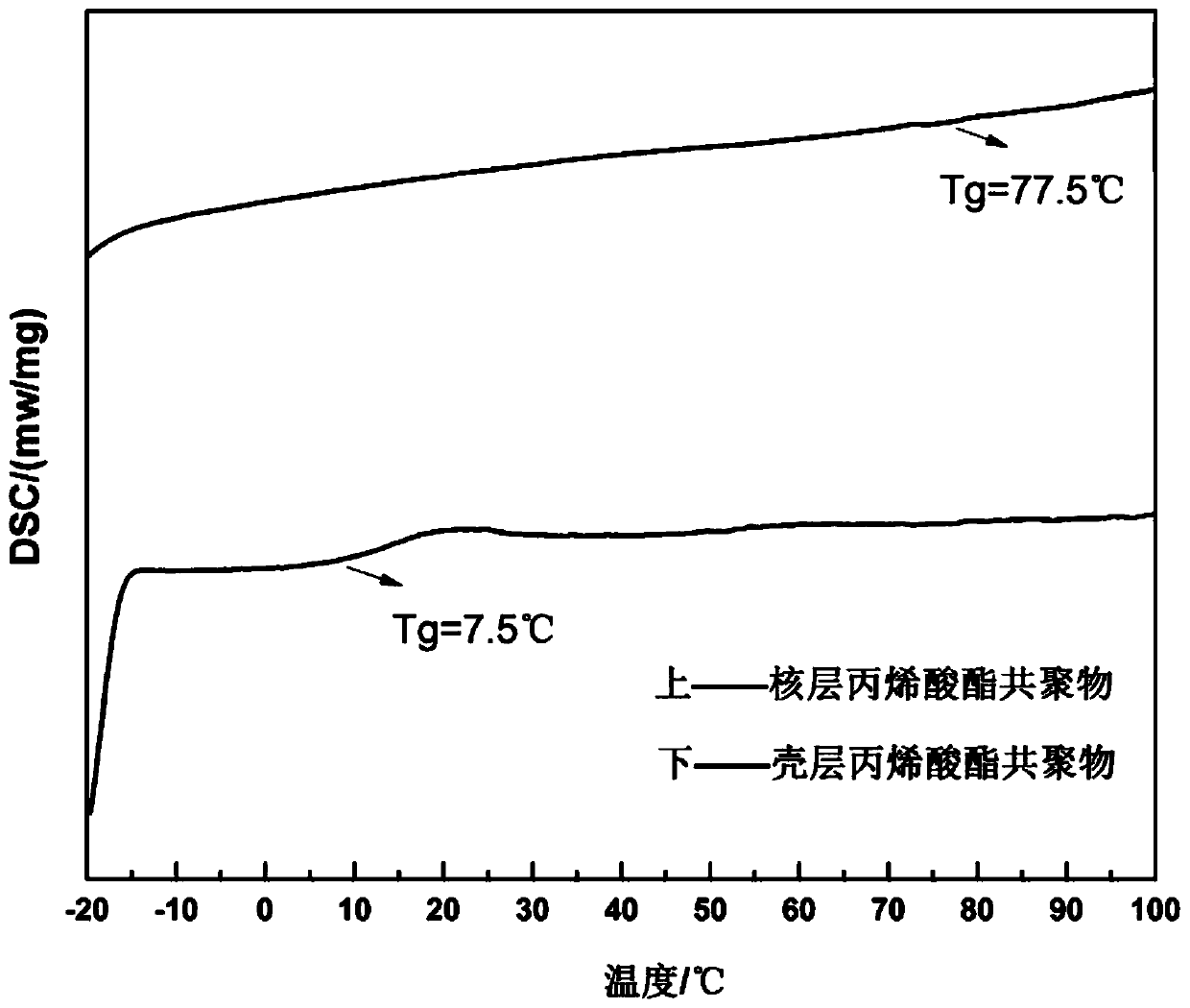

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com