Autocrine low-surface-energy flow-resistance-reducing paint

A low surface energy, coating technology, applied in the direction of coating, etc., can solve the problems of easy attenuation of low surface energy properties, loss of drag reduction effect, etc., and achieve low surface energy, excellent low surface energy properties, and excellent self-secretion regulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

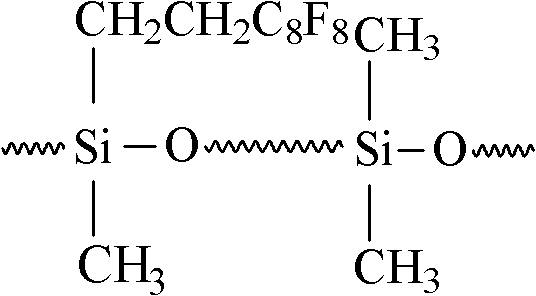

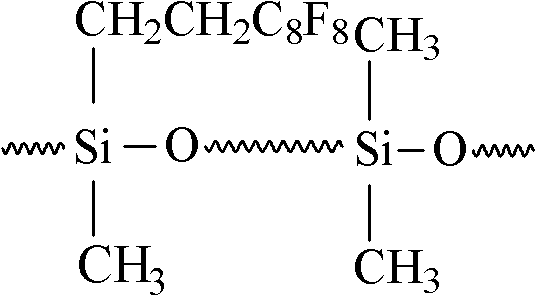

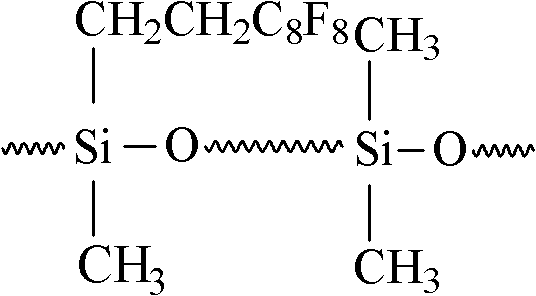

Method used

Image

Examples

Embodiment 1

[0039] Example 1: 60 parts of film-forming resin (normal temperature cross-linking type fluorocarbon resin) in proportion, 0.3 part of defoamer (Defom8700), 0.5 part of leveling agent (Levelol 495), solvent (by butyl acetate and xylene 10 parts of mixed solvents mixed with a volume ratio of 7:3), mixed uniformly to make fluorocarbon varnish; 20 parts of the above-mentioned fluorosilicon polymer microcapsules and 10 parts of toluene diisocyanate TDI curing agent were added to 70 parts of fluorocarbon varnish, mixed Stir evenly to obtain the self-secreting low surface energy flow-resistance coating.

[0040] The self-secreting low surface energy flow resistance reducing coating is coated on the steel substrate coated with anti-corrosion coating to make a sample, and after being fully dried at room temperature, the coating performance is tested. Within 12 months, the contact angle between the coating and water remained at 118°, and the flow resistance reduction effect remained at...

Embodiment 2

[0042] In proportion, 80 parts of film-forming resin (normal temperature cross-linking fluorocarbon resin), 0.8 parts of defoamer (Defom 8700), 1 part of leveling agent (Levelol 495), solvent (by butyl acetate and xylene in a ratio of 7: 3 volume ratio of mixed solvent) 40 parts, mix evenly to make fluorocarbon varnish. Add 40 parts of the above-mentioned fluorosilicon polymer microcapsules and 15 parts of curing agent (toluene diisocyanate TDI) to 90 parts of fluorocarbon varnish, mix and stir evenly to obtain the self-secreting low surface energy flow resistance reducing coating.

[0043] The self-secreting low surface energy flow resistance reducing coating is coated on the steel substrate coated with anti-corrosion coating to make a sample, and after being fully dried at room temperature, the coating performance is tested. Within 12 months, the contact angle between the coating and water remained at 120°, and the flow resistance reduction effect remained at 15%.

Embodiment 3

[0045] In proportion, 70 parts of film-forming resin (normal temperature cross-linking fluorocarbon resin), 0.5 part of defoamer (Defom 8700), 0.8 part of leveling agent (Levelol 495), solvent (by butyl acetate and xylene at 7: 3 volume ratio of mixed solvent) 30 parts, mixed evenly to make fluorocarbon varnish. Add 30 parts of the above-mentioned fluorosilicon polymer microcapsules and 12 parts of curing agent (toluene diisocyanate TDI) to 80 parts of fluorocarbon varnish, mix and stir evenly to obtain self-secreting low surface energy flow resistance reducing coating.

[0046] The self-secreting low surface energy flow resistance reducing coating is coated on the steel substrate coated with anti-corrosion coating to make a sample, and after being fully dried at room temperature, the coating performance is tested. Within 12 months, the contact angle between the coating and water remained at 119°, and the flow resistance reduction effect remained at 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com