Anti-doodling paint and preparation method thereof

An anti-graffiti and coating technology, used in anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of building damage, time-consuming and laborious, and difficult to remove graffiti, and achieve rapid curing and film formation , high transparency, excellent stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

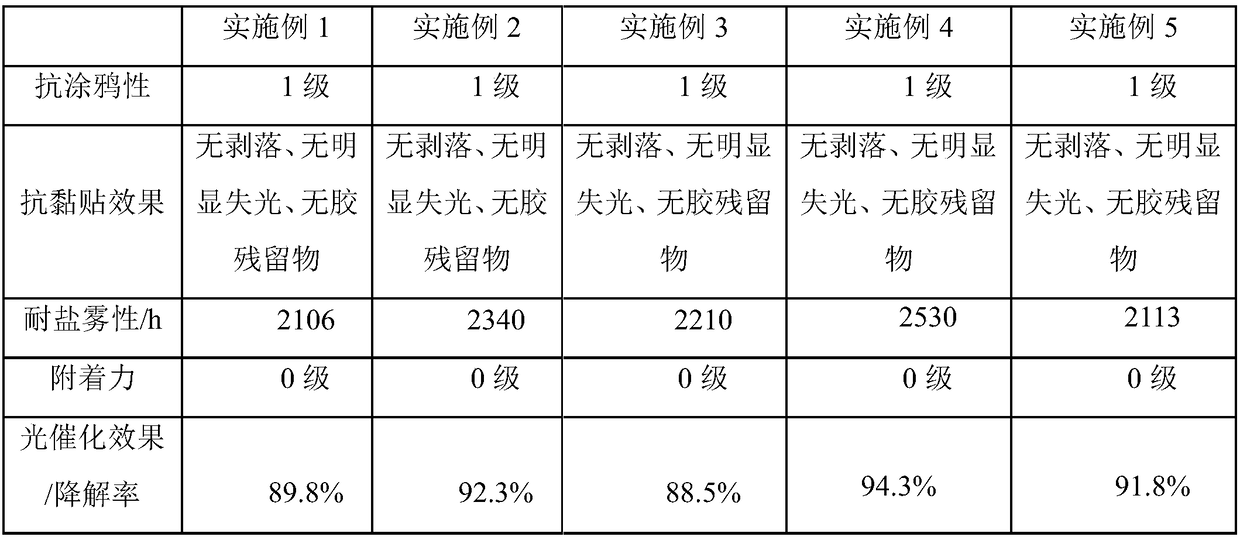

Examples

preparation example Construction

[0064] A kind of preparation method of anti-graffiti paint, described preparation method comprises the following steps:

[0065] Take 85-97 parts of modified organic-inorganic hybrid resin, 0.5-3 parts of titanate, 0.5-5 parts of nano-titanium dioxide, 0.5-5 parts of nano-cerium dioxide, and disperse 0.5-3 parts of antifoaming agent, 0.1-1.5 parts of defoaming agent, 0.5-2 parts of coupling agent for standby;

[0066] Add 20-30 parts of modified organic-inorganic hybrid resin, titanate, nano-titanium dioxide, nano-ceria, dispersant, defoamer, and coupling agent into the dispersion tank respectively, and stir at 25-50°C Obtain the initial mixed solution evenly, and the stirring time is 5min-20min;

[0067] The initial mixed solution is placed in an ultrasonic disperser for ultrasonic dispersion to obtain a mixed solution, and the dispersion time is 1-2 hours;

[0068] The mixed solution is placed in a dispersion tank, the remaining modified organic-inorganic hybrid resin is a...

Embodiment 1

[0074] step 1:

[0075] Preparation of acidic catalyst: mixing 1 g of phosphoric acid solution with a mass concentration of 10% and 10 g of hydrochloric acid solution with a mass concentration of 10%;

[0076] Preparation of organic solvent: 1 g of propylene glycol methyl ether acetate was mixed with 10 g of ethanol to form a mixed solution.

[0077] step 2

[0078] Stir 80g of tetraethyl orthosilicate, 5g of methyltriethoxysilane, and 5g of organic solvent at room temperature, raise the temperature to 80°C, add 5g of acidic catalyst and 5g of hydroxyfluorosilicone oil dropwise at the same time, and heat to reflux for reaction. For 5h, a modified organic-inorganic hybrid resin was obtained.

[0079] Step 3:

[0080] 20g of modified organic-inorganic hybrid resin, 0.5g of tetrabutyl titanate, 0.5g of nano-titanium dioxide, 0.5g of nano-cerium dioxide, 0.5g of silicone-modified polyacrylate, 0.5g of BYK-052 defoamer, γ - 0.5 g of aminopropyltriethoxysilane was added to the d...

Embodiment 2

[0086] step 1:

[0087] Embodiment 2 is the same as steps 1 to 2 of embodiment 1, and steps 3 to 5 are as follows:

[0088] Step 3:

[0089] Mix 25g of modified organic-inorganic hybrid resin, 3g of tetrabutyl titanate, 5g of nano-titanium dioxide, 3g of nano-cerium dioxide, 2g of silicone-modified polyacrylate, 0.5g of BYK-052 defoamer, γ-aminopropyl 1.5 g of triethoxysilane was respectively added into the dispersion tank, and stirred evenly at 50° C. to obtain an initial mixed solution, and the stirring time was 5 minutes.

[0090] Step 4:

[0091] The initial mixed solution in step 3 was placed in an ultrasonic disperser for ultrasonic dispersion to obtain a mixed solution, and the dispersion time was 1.5 h.

[0092] Step 5:

[0093] Put the mixed solution in step 3 in a dispersion tank, add 60 g of modified organic-inorganic hybrid resin, and stir for 10 min at 40° C. to obtain an anti-graffiti coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com