Low surface energy polymer microcapsules and preparation method thereof

A low surface energy, polymer technology, applied in the direction of microcapsule preparation, microsphere preparation, coating, etc., can solve the problems of poor compatibility, no products, less research, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

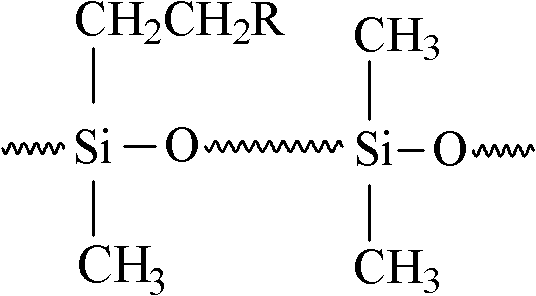

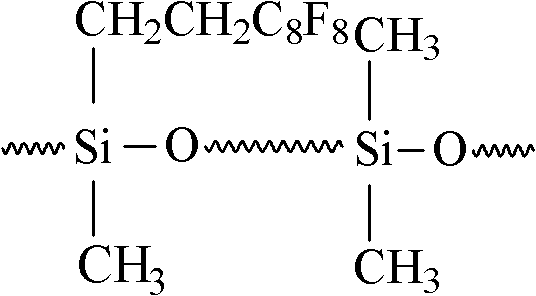

[0033] Embodiment 1: The low surface energy polymer core material adopts the fluorosilicon polymer satisfying the following formula:

[0034]

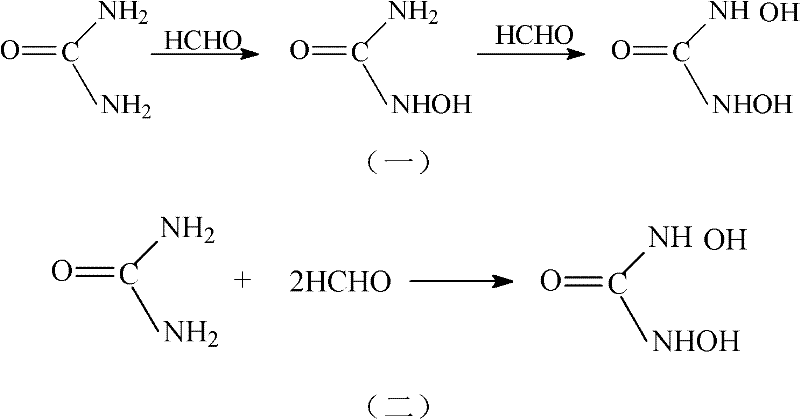

[0035] (1) Add 10 parts of urea and 35 parts of formaldehyde into the reaction flask, stir and mix, and adjust the pH of the mixture to 8-9 with 10% aqueous sodium carbonate solution.

[0036] (2) Heat the mixture in step (1) to 70° C. for 50 minutes to prepare a urea-formaldehyde resin prepolymer.

[0037] (3) Add 40 parts of fluorosilicone polymer, 1 part of Tween-80 dispersant and 250 parts of water into the dispersion container, and disperse for 10 minutes at a speed of 3000 rpm using a high-speed shear emulsifier.

[0038] (4) Add 45 parts of the urea-formaldehyde resin prepolymer prepared in step (2) dropwise into the dispersion at a rate of 20 drops / minute.

[0039] (5), after the dropwise addition, adjust the acidity of the dispersion in the above step (4) to pH 2-3 with glacial acetic acid.

[0040] (6) Heat the dispersio...

Embodiment 2

[0041] Embodiment 2: Low surface energy polymer core material adopts hydrogen-containing silicone oil

[0042] (1) Add 30 parts of urea and 50 parts of formaldehyde into the reaction flask, stir and mix, and adjust the pH of the mixture to 8-9 with 10% aqueous sodium carbonate solution.

[0043] (2) Heat the mixture in step (1) to 70°C and react for 50 minutes to prepare a urea-formaldehyde resin prepolymer.

[0044] (3) Add 60 parts of methyl silicone oil, 2 parts of Tween-80 dispersant and 300 parts of water into the dispersion container, and use a high-speed shear emulsifier to disperse at a speed of 3000 rpm for 10 minutes.

[0045] (4) Add 80 parts of urea-formaldehyde resin prepolymer prepared in step (2) dropwise into the dispersion in step (3) at a rate of 30 drops / min.

[0046] (5), after the dropwise addition, adjust the acidity of the dispersion in the above step (4) to pH 2-3 with glacial acetic acid.

[0047] (6) Heat the dispersion liquid in step (5) to 50° C. ...

Embodiment 3

[0048] Embodiment 3: low surface energy polymer core material adopts fluorinated acrylate

[0049] (1) Add 20 parts of urea and 40 parts of formaldehyde into the reaction flask, stir and mix, and adjust the pH of the mixture to 8-9 with 10% aqueous sodium carbonate solution.

[0050](2) Heat the mixture in step (1) above to 70° C. and react for 50 minutes to prepare a urea-formaldehyde resin prepolymer.

[0051] (3) Add 55 parts of fluorinated acrylate, 1.5 parts of Tween-80 dispersant and 280 parts of water into a dispersion container, and disperse for 10 minutes at a speed of 3000 rpm using a high-speed shear emulsifier.

[0052] (4) Add 60 parts of the urea-formaldehyde resin prepolymer prepared in the above step (2) dropwise into the dispersion at a rate of 25 drops / min.

[0053] (5), after the dropwise addition, adjust the acidity of the dispersion in the above step (4) to pH 2-3 with glacial acetic acid.

[0054] (6) Heating the dispersion liquid in step (5) to 60° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com