Novel load-bearing and heat-insulation integrated prefabricated fabricated-type shear wall and construction method

A prefabricated assembly and shear wall technology, applied in the direction of insulation, walls, building components, etc., can solve the problems of reducing the effective use area of the building, difficult to protect, and reducing the insulation effect of the insulation layer, so as to improve space utilization and prevent Damage, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

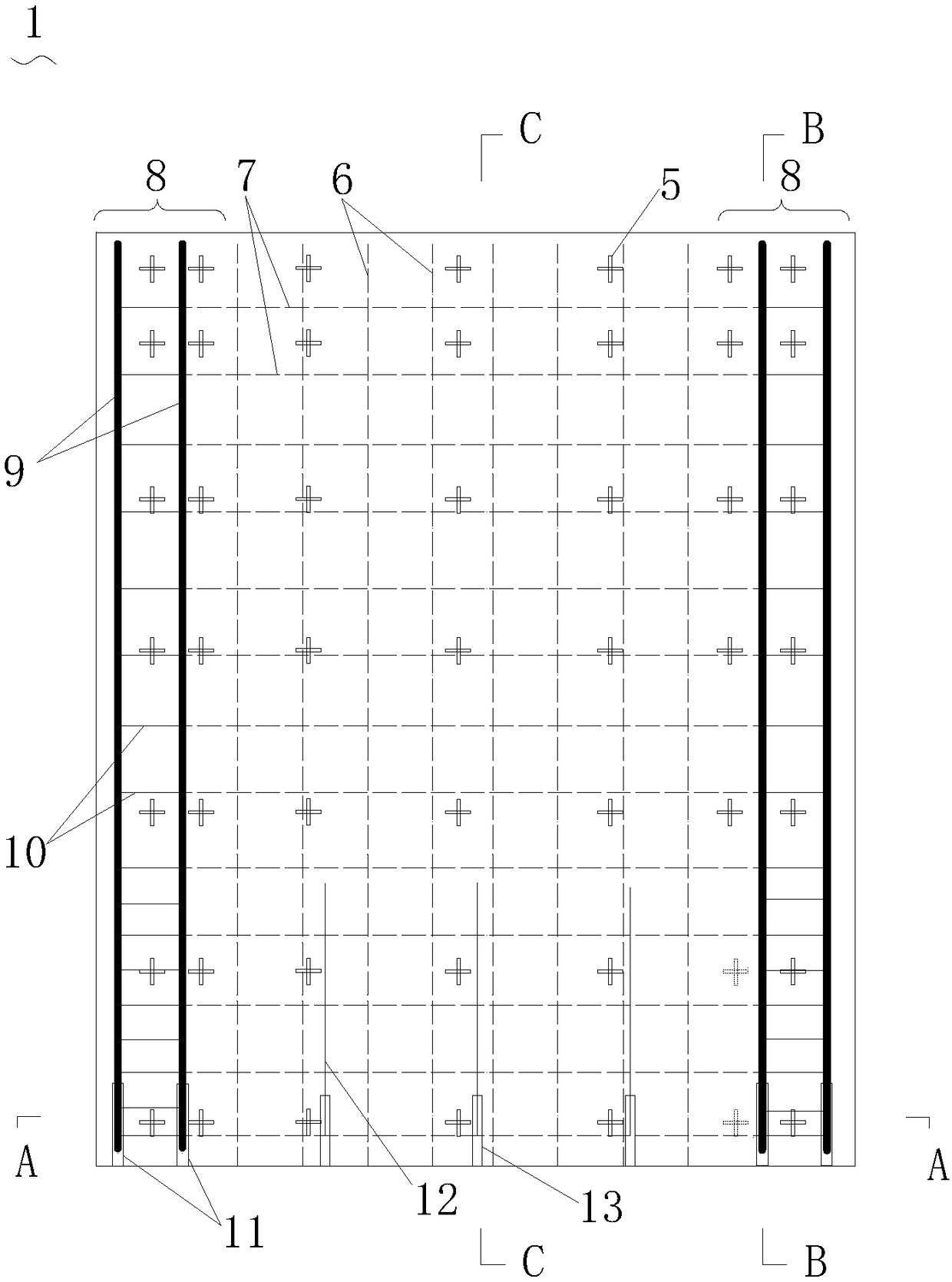

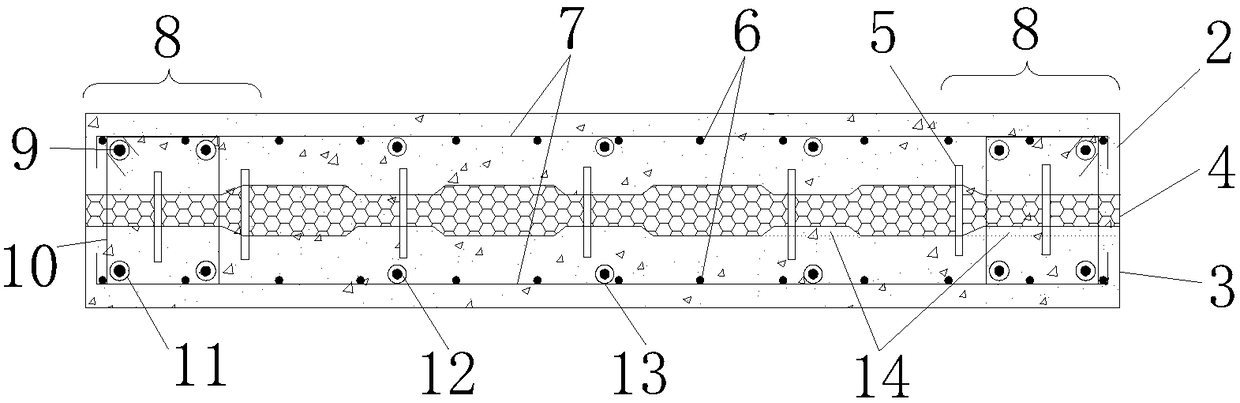

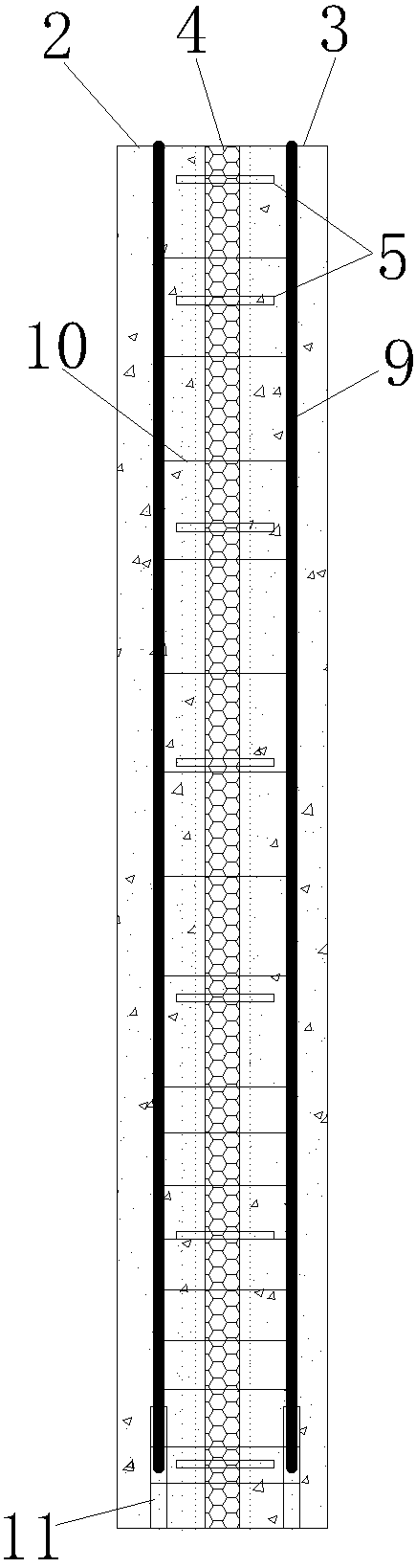

[0042] see figure 1 and figure 2 As shown, the load-bearing and thermal insulation integrated new type prefabricated shear wall 1 provided in this embodiment includes inner blades 2 , outer blades 3 , thermal insulation structure layer 4 and connectors 5 .

[0043] combine figure 1 , figure 2 and Figure 4 As shown, both the inner blade 2 and the outer blade 3 are equipped with a single-layer steel mesh composed of vertically distributed steel bars 6 and horizontally distributed steel bars 7 .

[0044] combine Figure 1 to Figure 4 As shown, the connector 5 passes through the thermal insulation structure layer 4, and the two ends are pre-embedded in the inner leaf plate 2 and the outer leaf plate 3 respectively. The connector 5 is made of fiber reinforced plastic (Fiber Reinforced Plastic, referred to as FRP). Fiber reinforced plastic has the characteristics of light weight and hard, non-conductive, low thermal conductivity, corrosion resistance, high mechanical strengt...

Embodiment 2

[0054] This embodiment provides a construction method of a new type of prefabricated prefabricated shear wall integrated with load-bearing and thermal insulation in Embodiment 1, combined below Figure 1 to Figure 4 The construction method is further described, specifically including the following steps:

[0055] S1. Lay the horizontally distributed steel bars 7, vertically distributed steel bars 6, longitudinally stressed steel bars 9 and steel sleeve 11 of the outer leaf plate 3, and tie the stirrups 10 to the longitudinally stressed steel bars 9 with steel wires, and then pour concrete The outer vane 3 is formed. When laying horizontally distributed steel bars 7, vertically distributed steel bars 6, and longitudinally stressed steel bars 9, the thickness of the protective layer that meets the requirements should be ensured. The two open ends of the stirrup 10 are arranged vertically upward.

[0056] S2. Before the initial setting of the concrete of the outer leaf plate 3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com