Capacitor and method of connecting the same

A technology of capacitors and external connection terminals, applied in the direction of capacitors, electrolytic capacitors, capacitor terminals, etc., can solve the problems of shortening the life of capacitors, deteriorating rubber parts, reducing sealing performance, etc., to suppress chemical deterioration, reduce contact resistance, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

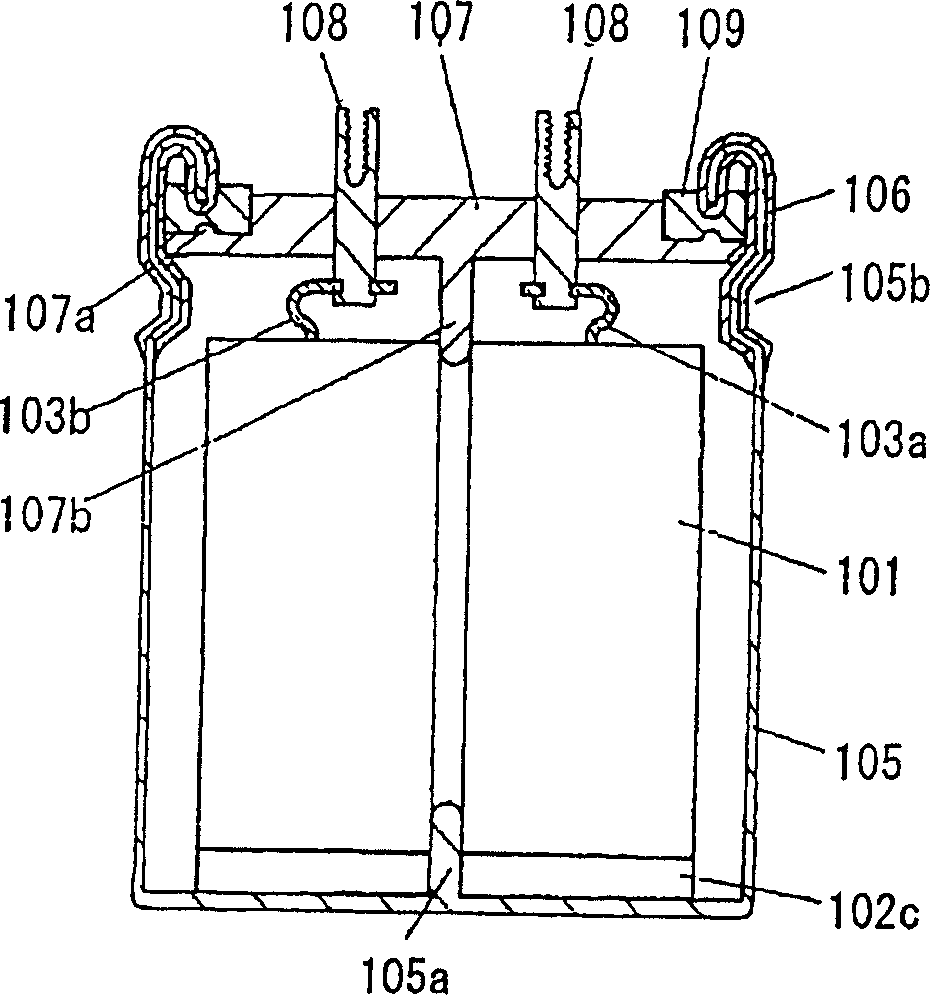

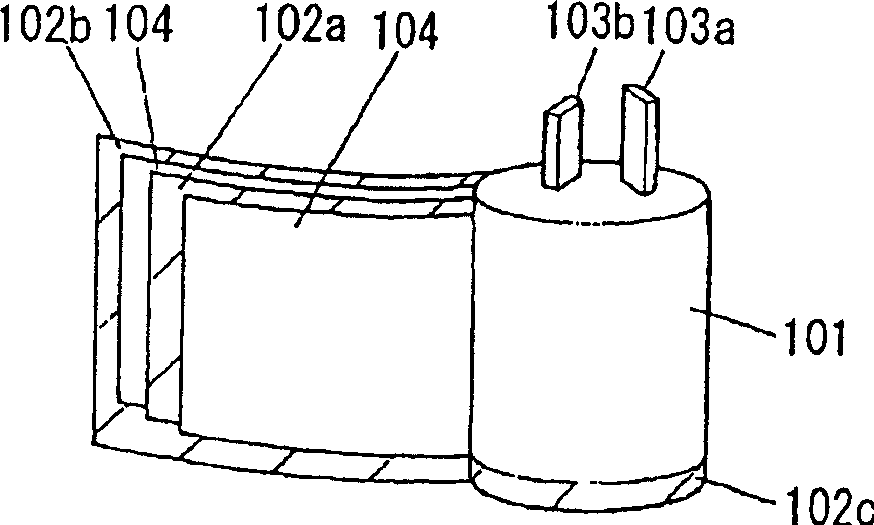

[0080] figure 1 is a sectional view showing the structure of the first embodiment of the capacitor of the present invention, and figure 2 is an expanded perspective view of the capacitor element used in this capacitor. exist figure 1 , reference numeral 101 indicates a capacitor element, and as figure 2 As shown, by respectively connecting the lead wires 103a and 103b with a pair of electrodes 102a and 102b, and then winding these electrodes into a roll with the isolation layer 4 disposed therebetween in such a way that one end surface 102c of an electrode 102b protrudes into a roll. Capacitor element 101 . Polarizable electrodes each composed of a mixture including at least activated carbon, a binder, and a conductive agent are formed on the electrode pairs 102a and 102b, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com