Marine floating type garbage recycling device driven by wave energy

A recovery device and wave energy technology, applied in the field of marine environment cleaning, can solve problems such as time-consuming, labor-intensive, low efficiency, and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

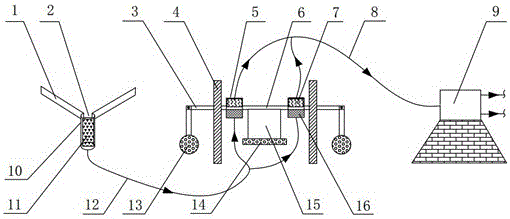

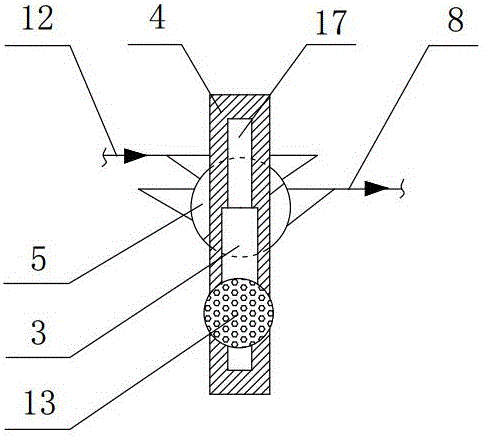

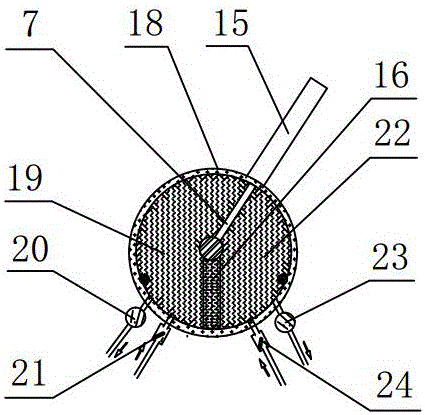

[0026] Such as figure 1 As shown, a wave energy-driven offshore floating garbage recovery device provided by the present invention includes a floating water garbage can 10, an oil and dirt separation tank 9 and a wave energy water pump 5 arranged on the wave energy capture device. Wherein the floating water trash can 10 is set at the center point of the two floating fences 1 in the shape of a "V", and a notch 2 is provided on the top of the floating water trash can 10, and the opening depth of the notch 2 is slightly lower than that of the liquid. On the surface, two floating barriers 1 are respectively arranged on the two side edges of the notch 2, so that the angle between the two floating barriers 1 is 90~165 o . The two floating fences 1 in the shape of a "V" intercept sea floating garbage. Under the action of offs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com