Centrifugal water and gas separation window-cleaning machine

A technology for water-air separation and window cleaning, which is used in cleaning machinery, machine parts, and window cleaning. Water and gas separation, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings, and the aforementioned and other objects, features, aspects and advantages of the present invention will become more apparent, so that those skilled in the art can implement them with reference to the description.

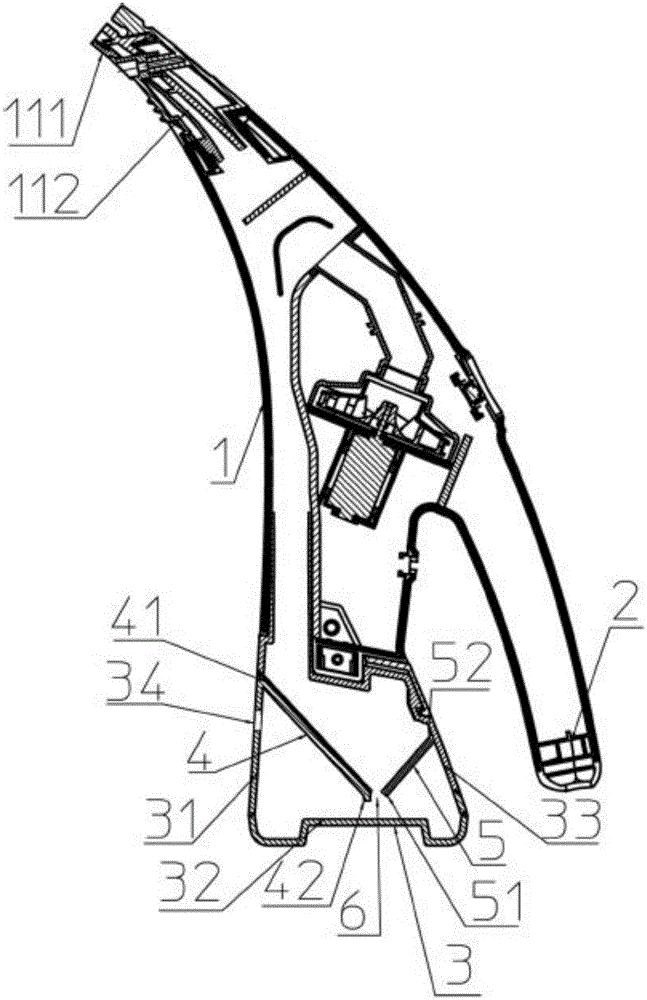

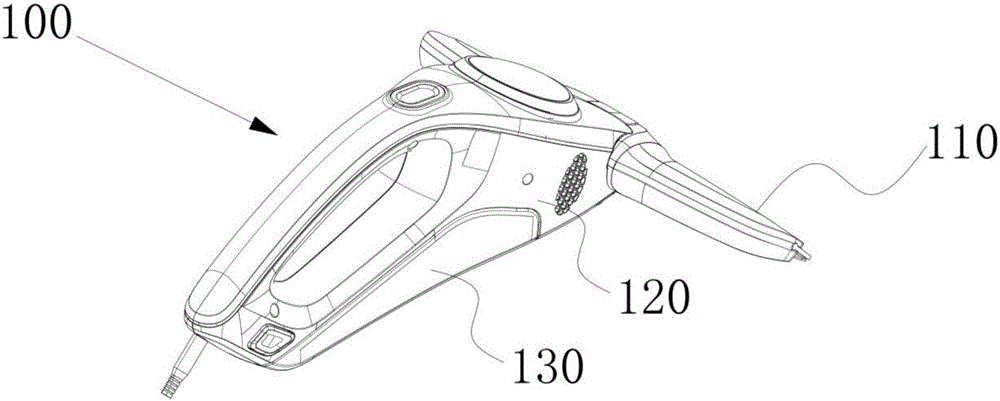

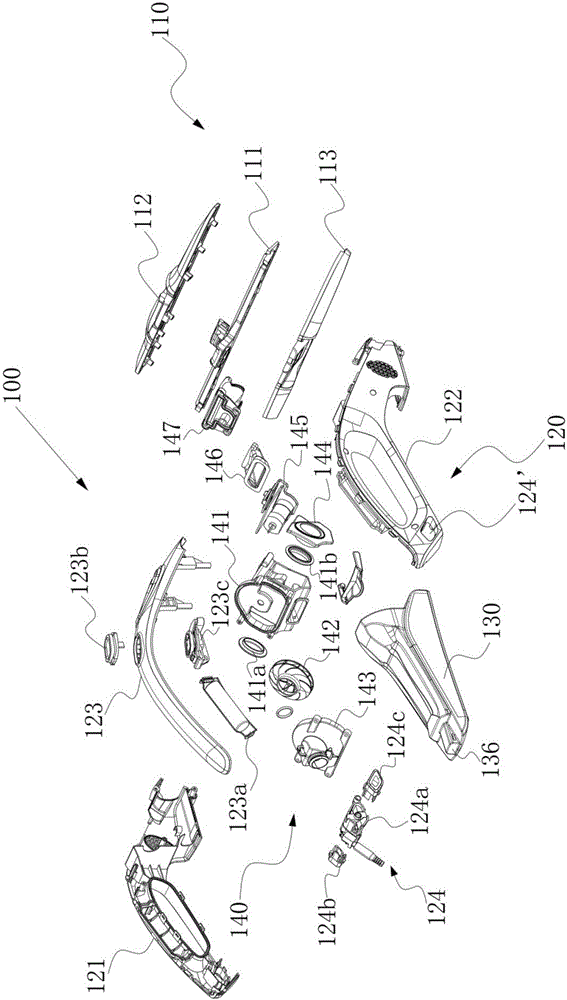

[0040] refer to figure 2 and image 3 , The window cleaning machine 100 of centrifugal water and air separation includes: a suction nozzle assembly 110 , a housing assembly 120 , a water tank assembly 130 and a water and air separation assembly 140 . Wherein, the suction nozzle assembly 110 is pluggably connected to the front end of the housing assembly 120, and the suction nozzle assembly includes a suction nozzle upper cover 112, a suction nozzle 111, and a suction nozzle lower cover 113 laid in a sandwich structure from top to bottom. ; The housing assembly 120 has a certain internal space, referring to Figure 8 , Figure 9 and Figure 10 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com