Tobacco leaf sorting platform

A tobacco leaf and sorting technology, which is applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of low production efficiency and high labor intensity, and achieve the effects of simple structure, exquisite structure and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

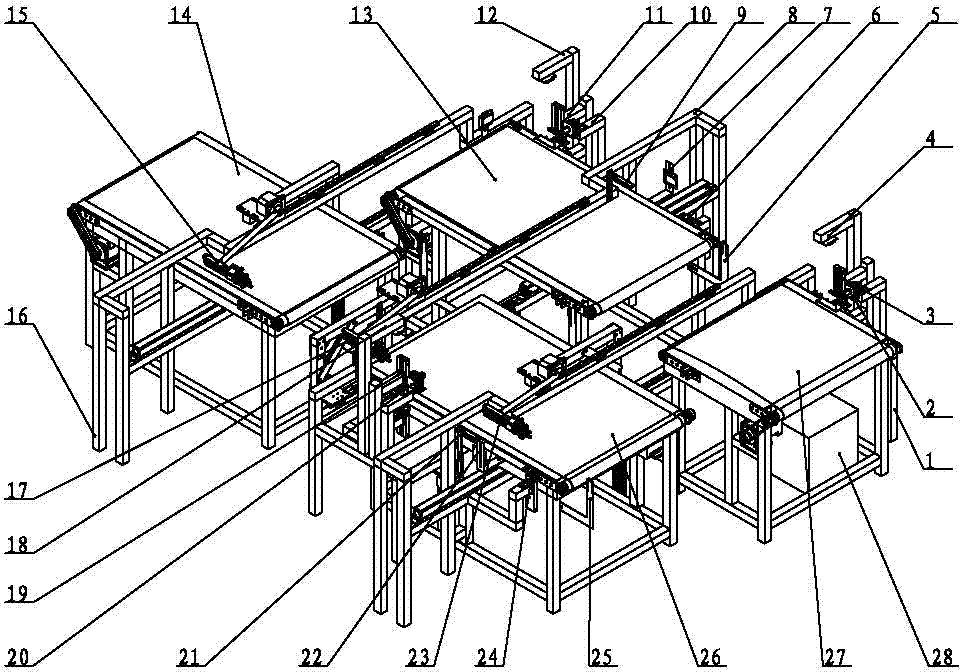

[0031] A kind of tobacco leaf sorting platform, it comprises four conveyor belts at least, such as figure 1 as shown, figure 1 Four conveyor belts 27, 26, 13 and 14 have been designed in total. During specific implementation, corresponding conveyor belts can be added as needed. The driving structure of the conveyor belt is the structure commonly used in conventional textbooks or design manuals. Each conveyor belt can be Driven by an independent motor, wherein the first conveyor belt 27 is a feeding belt, the last one, that is, the fourth conveyor belt 14, is a discharge belt, and the second conveyor belt 26 and the third conveyor belt 13 are for gradually reducing the amount of tobacco leaf transmission. Dispersing belts, the first conveyor belt 27 and the second conveyor belt 26 are arranged side by side and misplaced, the third conveyor belt 13 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com