A dual-power automatic sorting garbage removal device

An automatic sorting and dual-power technology, applied in the directions of magnetic separation, transportation and packaging, solid separation, etc., can solve the problem of reducing the resistance of the dual-power automatic sorting garbage removal device to facilitate transfer and avoid friction small force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

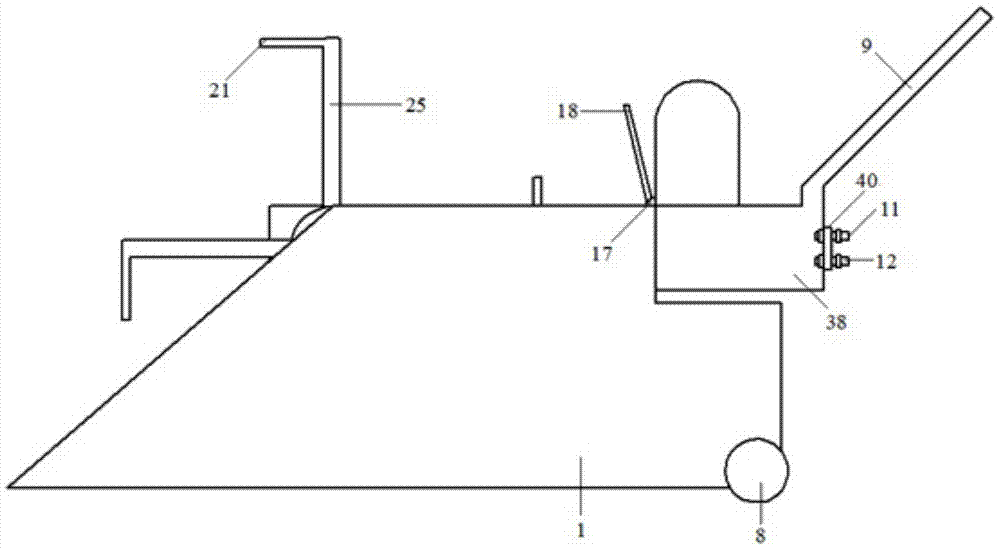

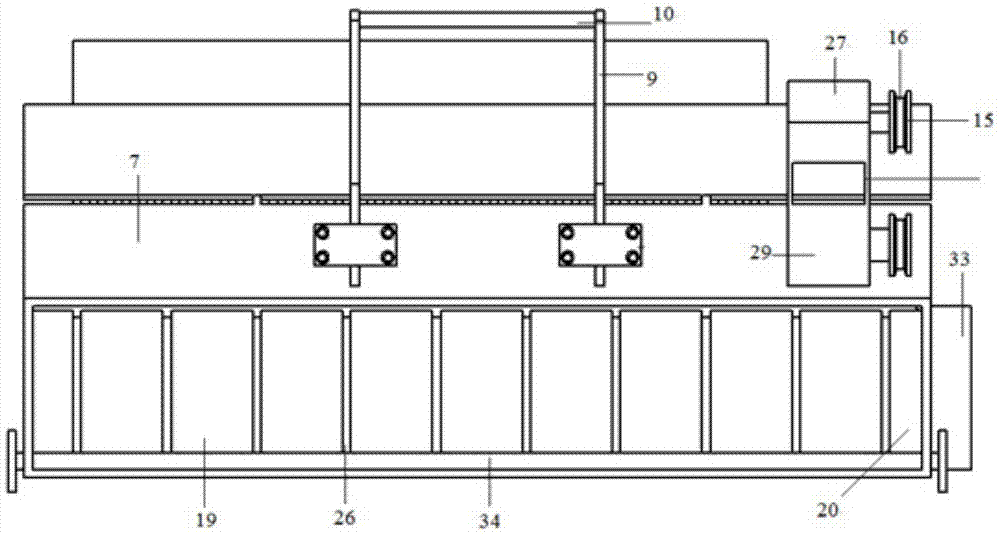

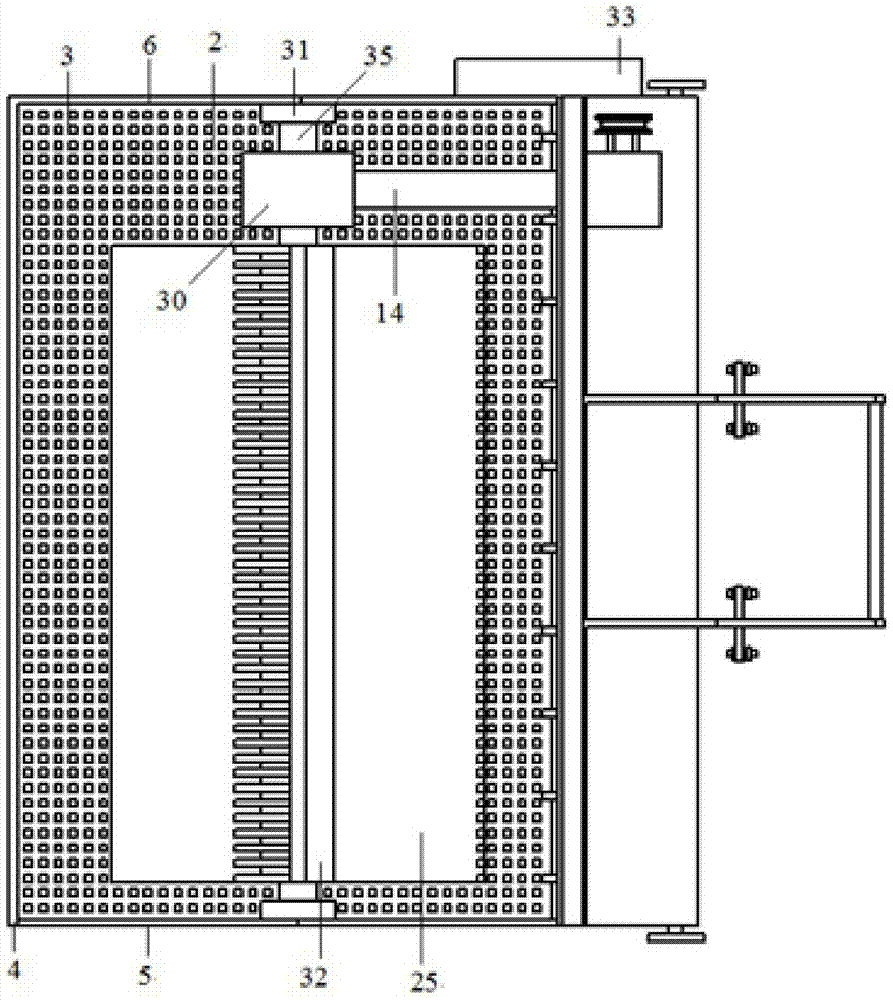

[0026] Specific implementation mode 1: Combination Figure 1-9 As shown, including housing 1, bottom plate 2, ramp 4, left side plate 5, right side plate 6, rear side plate 7, wheels 8, strut 9, armrest 10, bolt 11, nut 12, bearing 13, drive shaft 14, V belt wheel 15, hinge 17, magnetic cover 18, conveyor belt 19, roller 20, rake teeth 21, spur gear 22, bevel gear 23, A-type baffle 25, B-type baffle 26, A-type motor 27, B type motor 28, A gear box 29, B gear box 30, A type sleeve 31, B type sleeve 32, square sleeve 33, A shaft 34, B shaft 35, C shaft 36, D shaft 37, A type Rib 38, type B rib, type A support plate 40, type B support plate 41; the left side plate 5 is arranged on the left side of the housing 1; the right side plate 6 is arranged on the right side of the housing 1; the rear side plate 7 is arranged Behind the housing 1; the bottom plate 2 is set at the bottom of the housing 1; the bottom of the left side plate 5 and the bottom of the right side plate 6 are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com