Equidirectional drainage reverse taper type high-efficiency rotational flow separator

A cyclone separator, high-efficiency technology, applied in the direction of the cyclone device, the axial direction of the cyclone can be reversed, etc., can solve the problems of increasing construction difficulty, unstable flow field, inconvenient connection, etc. The effect of small area, small equipment volume and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

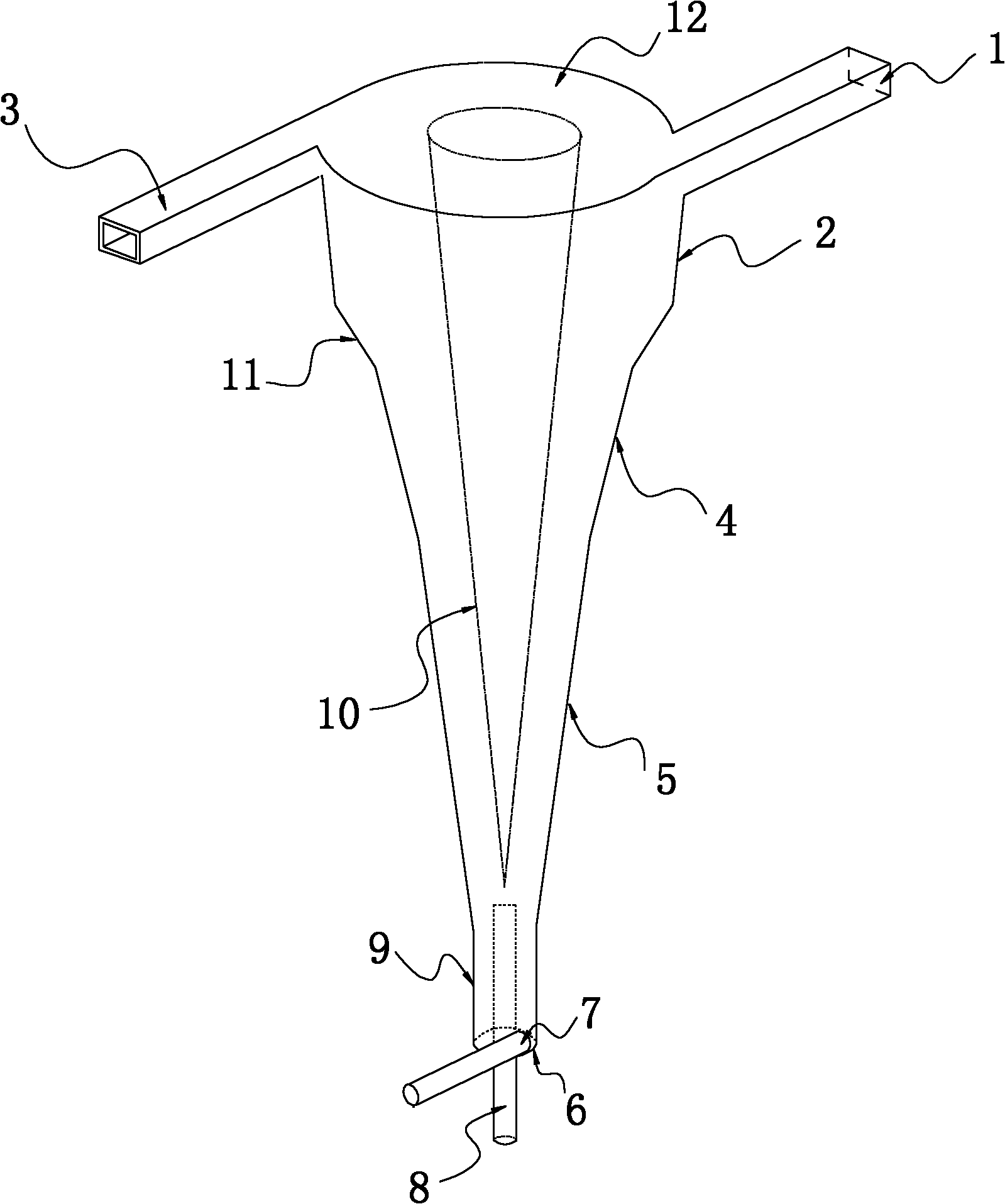

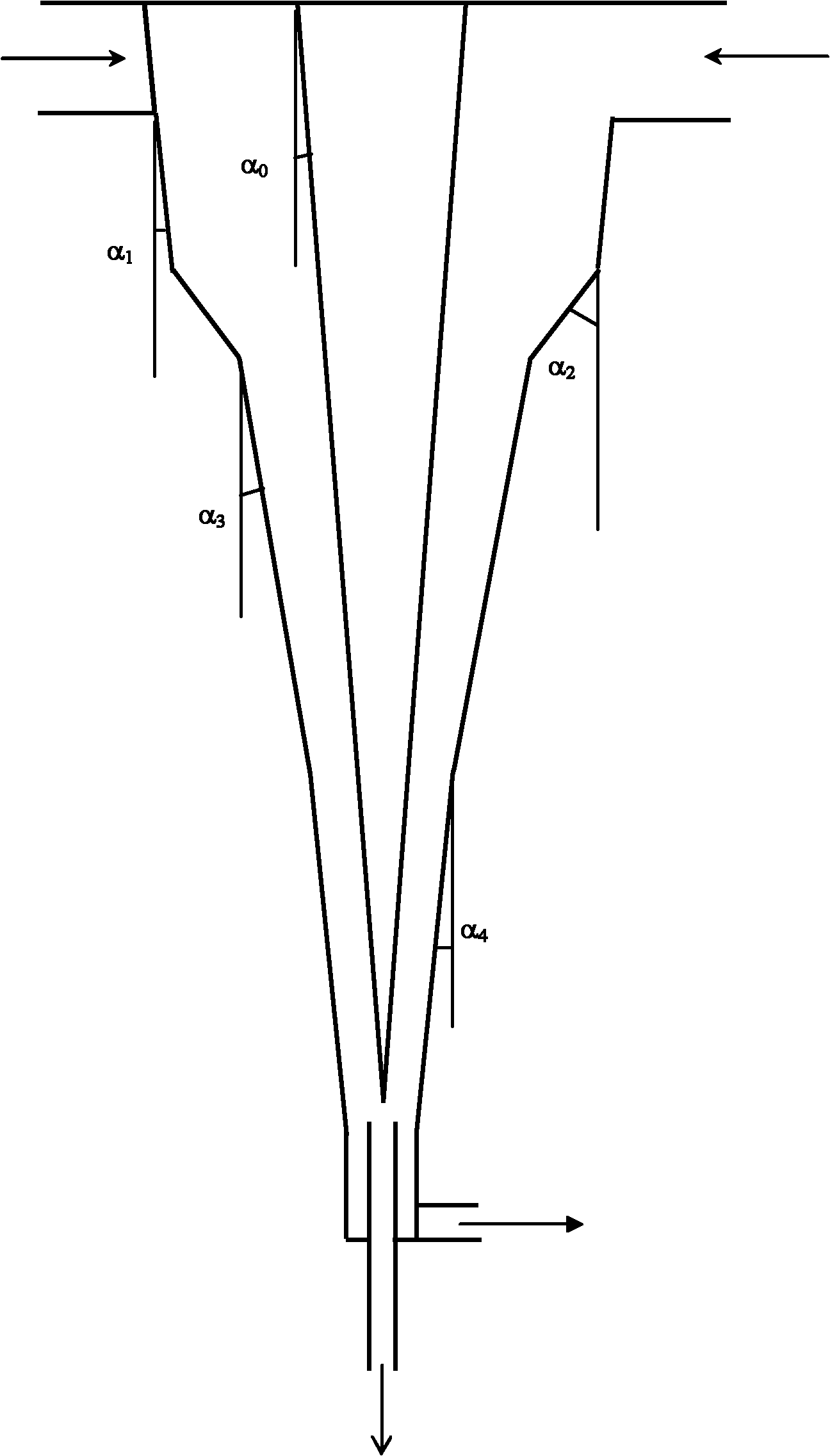

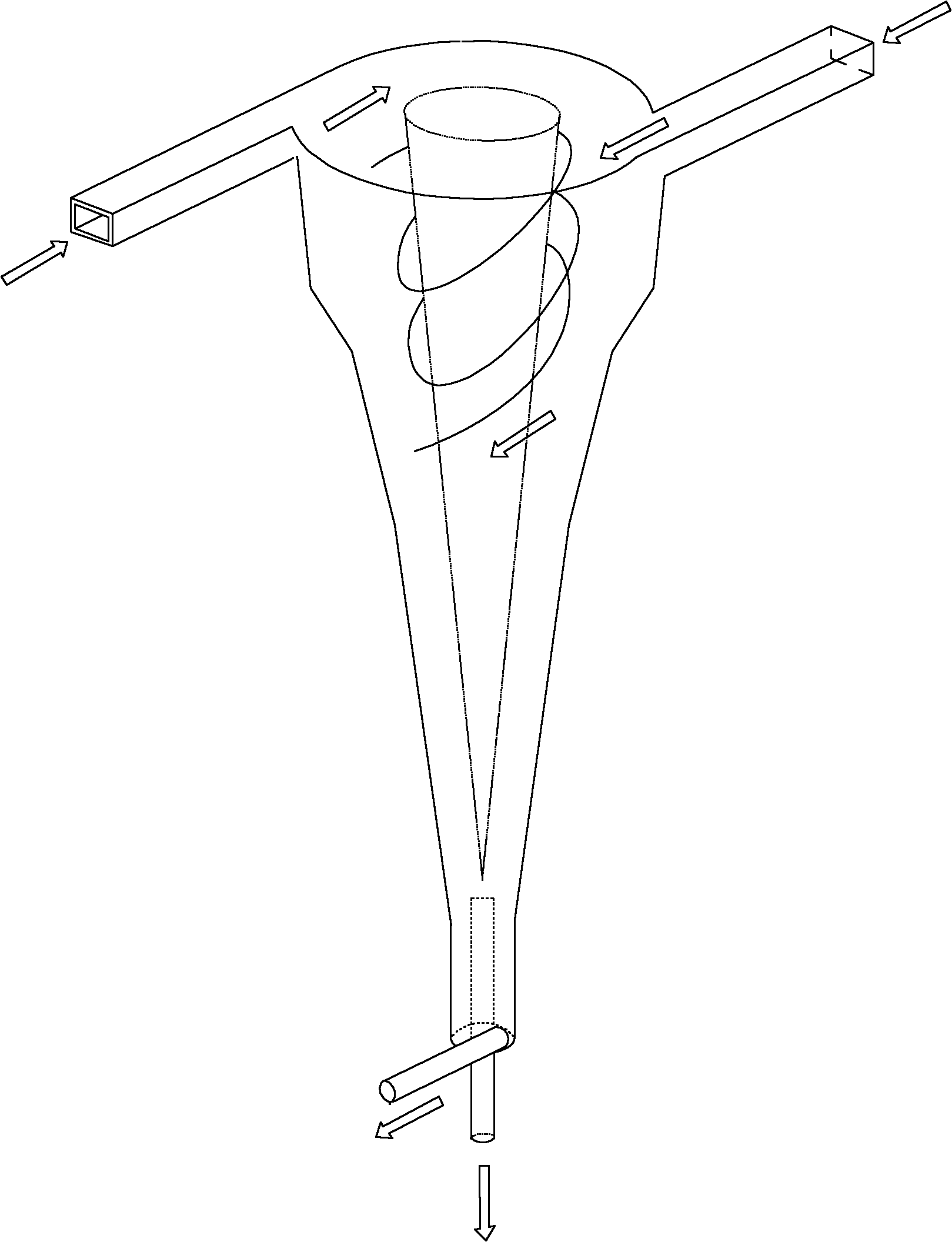

[0017] Such as figure 1 As shown, this kind of outflow reverse cone high-efficiency cyclone separator in the same direction includes the inlet pipe 1 of No. The general hydrocyclone structure such as the upper sealing surface 12 and the lower sealing surface 6 at the end, but the unique feature is that this kind of cyclone separator abandons the conventional cylindrical cyclone cavity, and adopts the above, Between the lower sealing surfaces, there are structures such as a truncated swirl chamber section 2 , a large cone section 11 , a small cone section 4 , a tailpipe section 5 and a cylindrical outlet section 9 in sequence. In this new structure, the upper sealing surface 12, the swirl cavity section 2, the large cone section 11, the small cone section 4, the tailpipe section 5, the outlet section 9 and the lower sealing surface 6 are sequentially connected to form an I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com