Jet type gas/solid erosion test device

A test device, a jet-type technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of inaccurate control of the impact angle and unstable flow field, etc., to achieve stable flow field and accurate impact angle The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

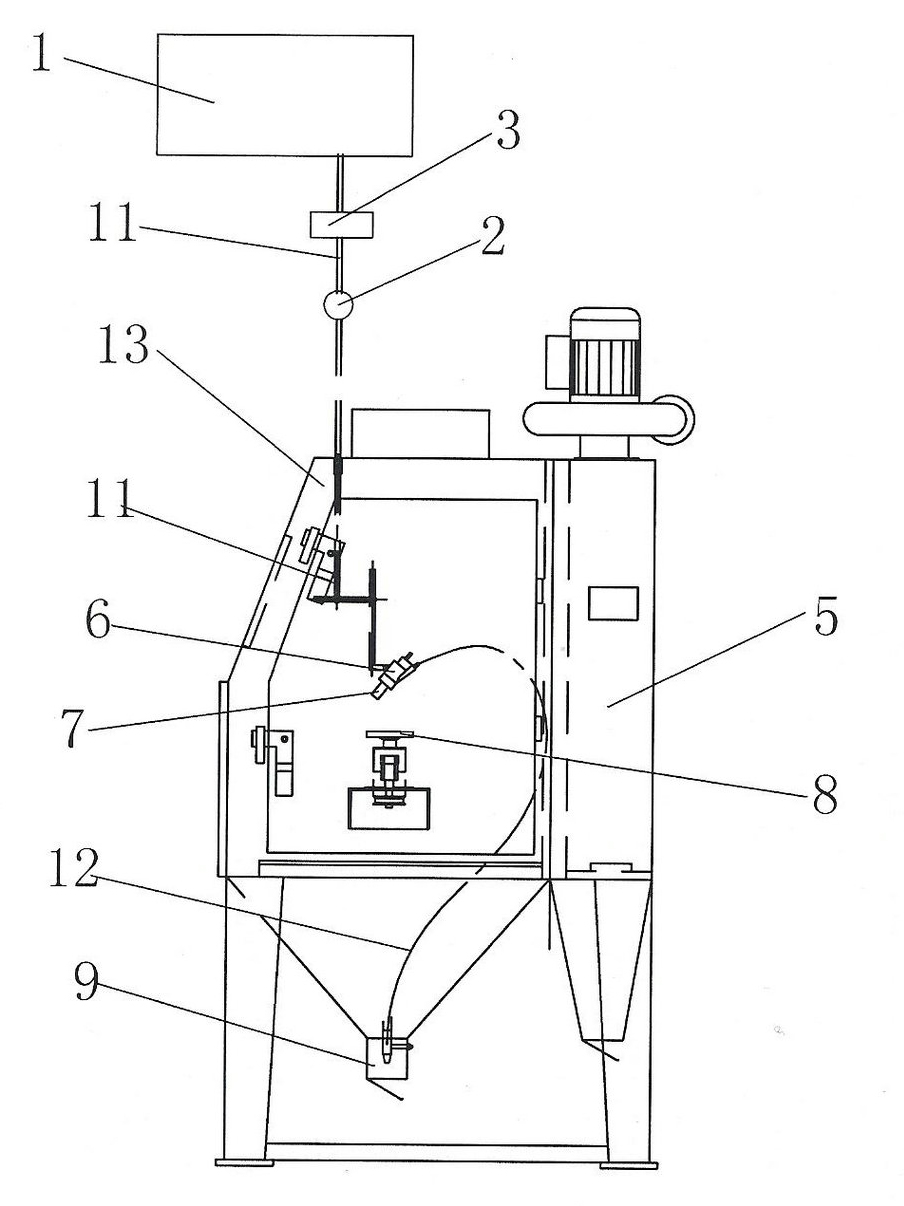

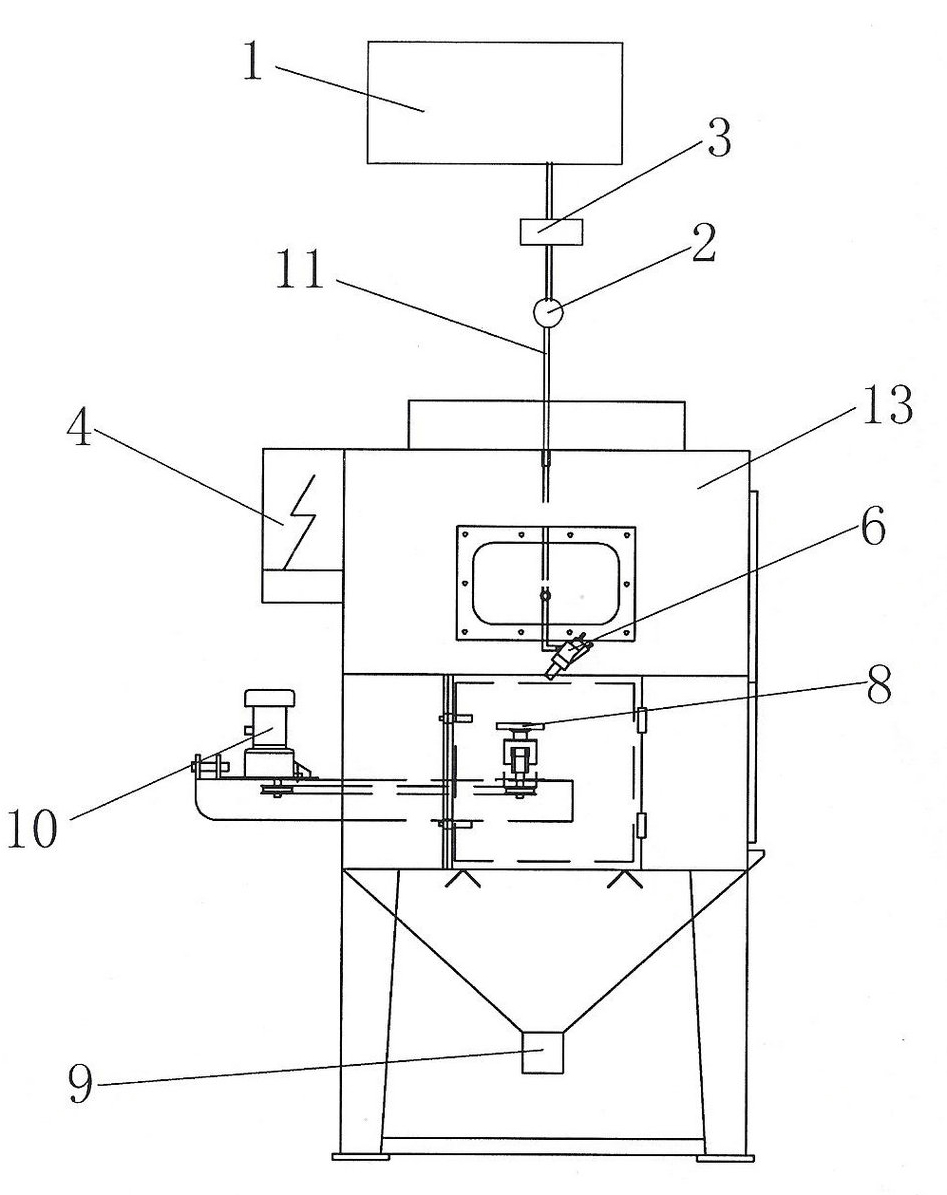

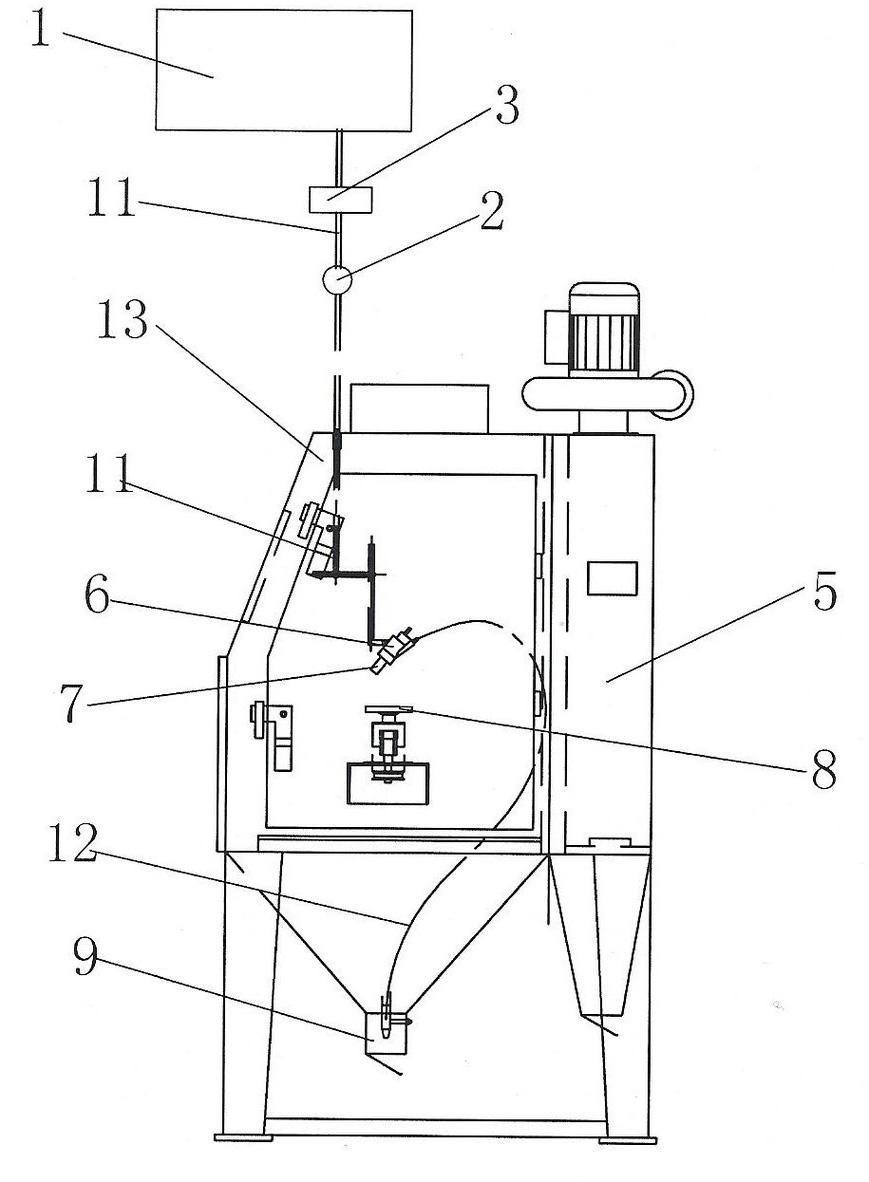

[0012] see figure 1 and figure 2 Shown, be the embodiment of the present invention, this embodiment is made up of air compressor 1, pressure gauge 2, pressure control valve 3, control box 4, deduster 5, spray gun 6, nozzle 7, sample turntable 8, store sand Chamber 9, frequency conversion motor 10, gas delivery pipe 11, sand delivery pipe 12 and machine body 13, the air compressor 1 communicates with the spray gun 6 through the gas delivery pipe 11, and the gas delivery pipe 11 is provided with a pressure gauge 2 and a pressure control valve 3 The lower end of the spray gun 6 has a nozzle 7, the sample turret 8 is located below the nozzle 7, the sample turret 8 is driven to rotate by a frequency conversion motor 10, the sand storage chamber 9 communicates with the spray gun 6 through a sand delivery pipe 12, the spray gun 6 and the sample turret 8 are located In the closed body 13, the sand storage chamber 9 is located at the bottom of the body 13, the air compressor 1, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com