Experimental device and method for mechanical sealing through ball sealers

A mechanical plugging and experimental device technology, applied in the field of plugging ball plugging casing, can solve the problem of lack of minimum fluid displacement, etc., and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

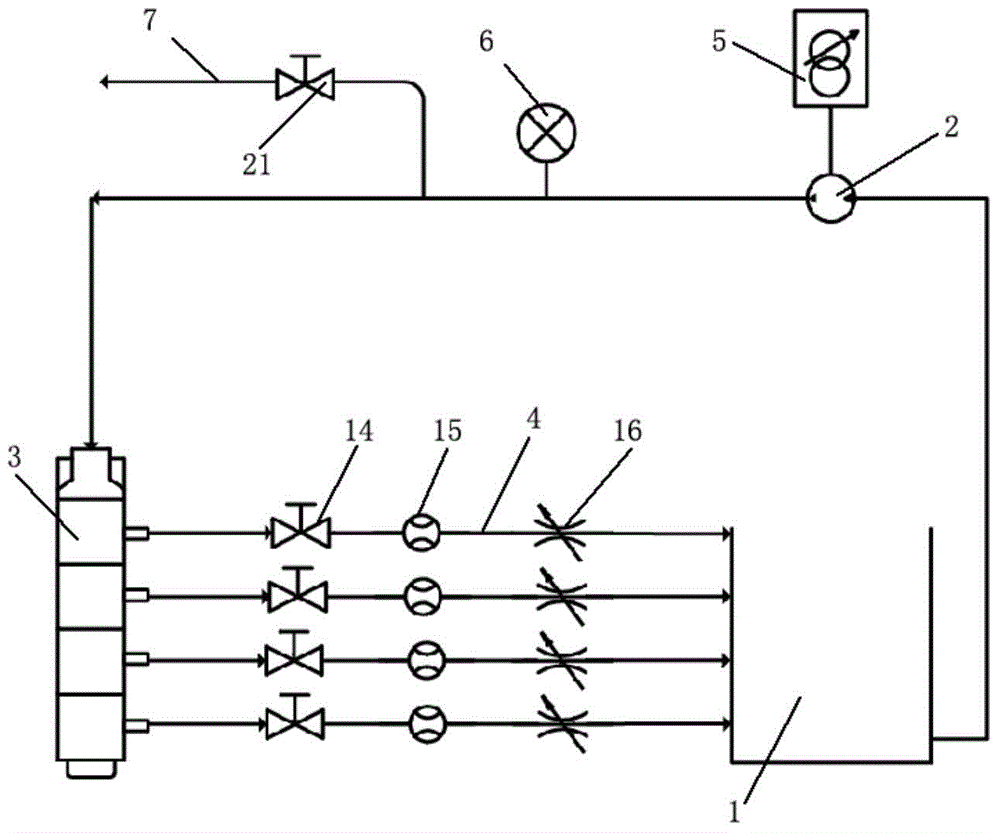

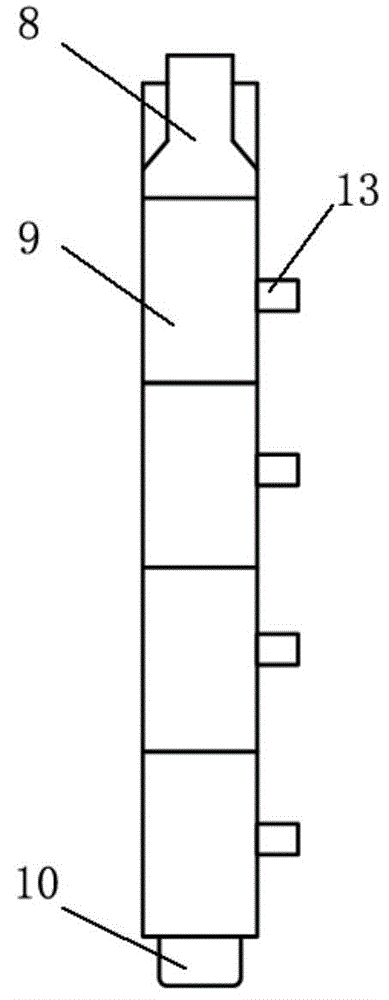

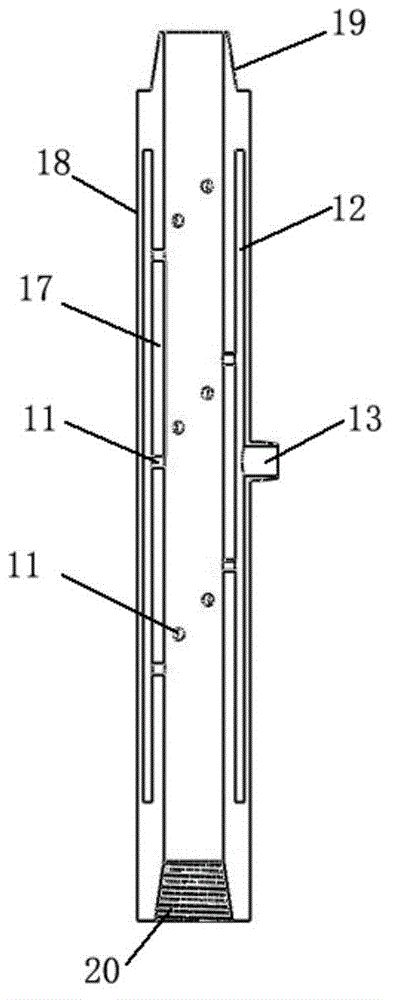

[0043] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a kind of mechanical plugging experiment device and method of plugging ball,

[0044] The plugging ball mechanical plugging experiment device includes: water tank 1, electric plunger pump 2, experimental string 3, 4 water absorption control tubes 4, frequency converter 5, pressure gauge 6 and pressure relief tube 7. The experimental string 3 is composed of joints 8, four perforated casings 9 and casing plugs 10 connected sequentially from top to bottom, and the four perforated casings 9 are numbered 1 to 4 from top to bottom. The four water absorption control pipes 4 corresponding to the perforated sleeves are also numbered No. 1 to No. 4. The water tank 1 of the experimental device is connected to the suction port of the electric plunger pump 2 through the water supply pipeline, and the water outlet of the electric plunger pump 2 is connected to the joint 8 of the experimental column 3 through the pumping pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com