Co-rotating outflow internal-hole type high performance swirling separator

A cyclone separator, a high-efficiency technology, applied in the direction of the cyclone device, the device whose axial direction of the cyclone remains unchanged, etc., can solve the problems such as difficulty in meeting the water injection requirements, low oil removal efficiency in the settling section, and increased load on the filtration section , to achieve the effect of flexible and convenient process installation, improved treatment effect and improved deoiling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

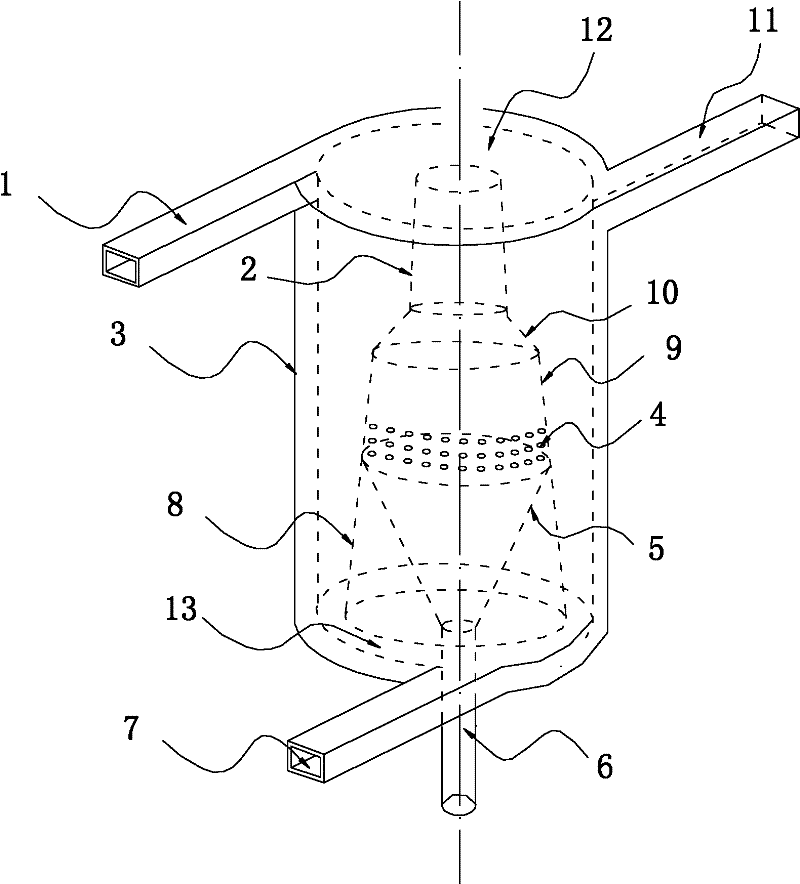

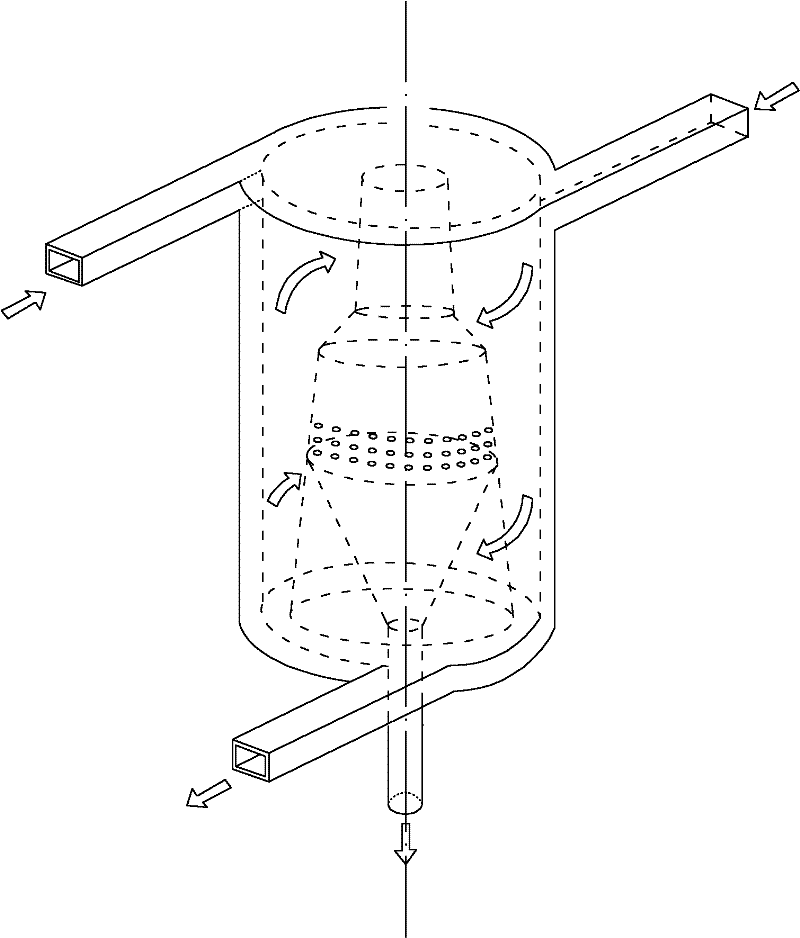

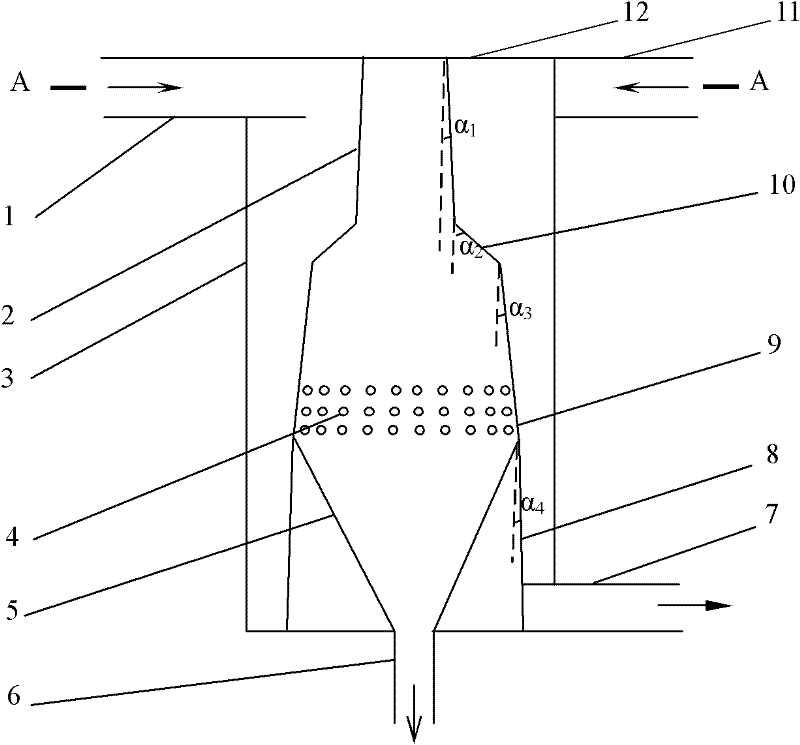

[0012] This kind of high-efficiency cyclone separator with internal holes flowing in the same direction has a structure such as figure 1 combine image 3 , Figure 4 As shown, it includes the No. 1 inlet pipe 1 of the swirl flow, the No. 2 inlet pipe 11 of the swirl flow, the cylindrical outer swirl fluid 3 located on the same horizontal plane, and the upper sealing surface 12 and the Conventional structures such as the lower closed surface 13 are unique in that:

[0013] Between the upper and lower sealing surfaces, there is fixed a swirl cavity section inner cylinder 2, a large cone section inner cylinder 10, a small cone section inner cylinder 9 and a tailpipe section inner cylinder 8 which are sequentially connected from top to bottom. Conical multi-stage internal swirl fluid, the cavity formed between the inner wall of the outer swirl fluid 3 and the outer wall of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com