Detachable T-shaped microchannel device and method for preparing monodisperse polymer microspheres by same

A technology of microchannels and polymers, applied in chemical instruments and methods, pharmaceutical formulations, chemical/physical processes, etc., to achieve the effects of easy dredging, simple equipment, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

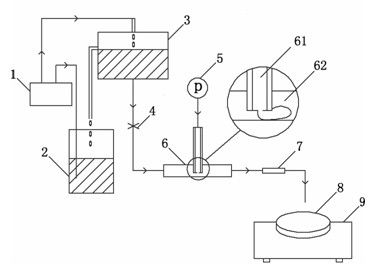

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of polylactic-co-glycolic acid (PLGA) microparticles

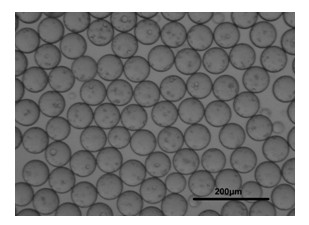

[0031] A T-shaped microchannel with a diameter of 129 μm at the needle tip of the dispersed phase and a 300 μm equivalent diameter of the continuous phase at the T-shaped nozzle is processed. A certain mass of polylactic acid-glycolic acid copolymer (molecular weight 15,000) was weighed and dissolved in dichloromethane to obtain a dispersed phase with a concentration of 1% g / ml. Weigh a certain mass of polyvinyl alcohol-124 and dissolve it in water to obtain a continuous phase with a concentration of 0.5% g / ml. Turn on the peristaltic pump in the constant flow device and adjust the flow rate to 20ml / min. Draw 10ml of the dispersed phase with a syringe, install the syringe into a syringe pump, and adjust the flow rate of the dispersed phase to 0.2ml / min. After the dispersed phase is injected into the T-shaped nozzle, open the water stop clamp, the continuous phase fluid enters the T-shaped pi...

Embodiment 2

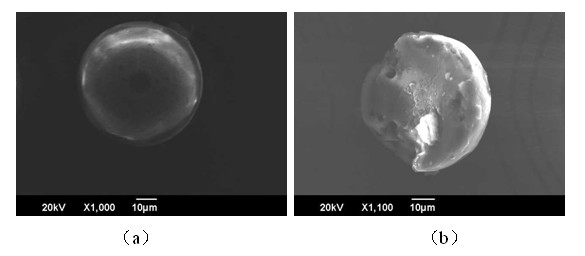

[0032] Example 2: Preparation of polylactic-co-glycolic acid (PLGA) microparticles

[0033] A T-shaped microchannel with a diameter of 129 μm at the needle tip of the dispersed phase and a 300 μm equivalent diameter of the continuous phase at the T-shaped nozzle is processed. A certain mass of polylactic acid-glycolic acid copolymer (molecular weight 15,000) was weighed and dissolved in dichloromethane to obtain a dispersed phase with a concentration of 1% g / ml. Weigh a certain mass of polyvinyl alcohol-124 and dissolve it in water to obtain a continuous phase with a concentration of 1% g / ml. Turn on the peristaltic pump in the constant flow device and adjust the flow rate to 20ml / min. Draw 10ml of the dispersed phase with a syringe, install the syringe into a syringe pump, and adjust the flow rate of the dispersed phase to 0.03 ml / min. After the dispersed phase is injected into the T-shaped nozzle, open the water stop clamp, the continuous phase fluid enters the T-shaped pipe...

Embodiment 3

[0034] Example 3: Preparation of polylactic-co-glycolic acid (PLGA) microparticles

[0035] A T-shaped microchannel with a diameter of 129 μm at the needle tip of the dispersed phase and a 300 μm equivalent diameter of the continuous phase at the T-shaped nozzle is processed. A certain mass of polylactic acid-glycolic acid copolymer (molecular weight 15,000) was weighed and dissolved in dichloromethane to obtain a dispersed phase with a concentration of 1% g / ml. Weigh a certain mass of polyvinyl alcohol-124 and dissolve it in water to obtain a continuous phase with a concentration of 1% g / ml. Turn on the peristaltic pump in the constant flow device and adjust the flow rate to 20ml / min. Draw 10ml of the dispersed phase with a syringe, install the syringe into a syringe pump, and adjust the flow rate of the dispersed phase to 0.4ml / min. After the dispersed phase is injected into the T-shaped nozzle, open the water stop clamp, the continuous phase fluid enters the T-shaped pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com