Soluble plug

A plug, cylindrical technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

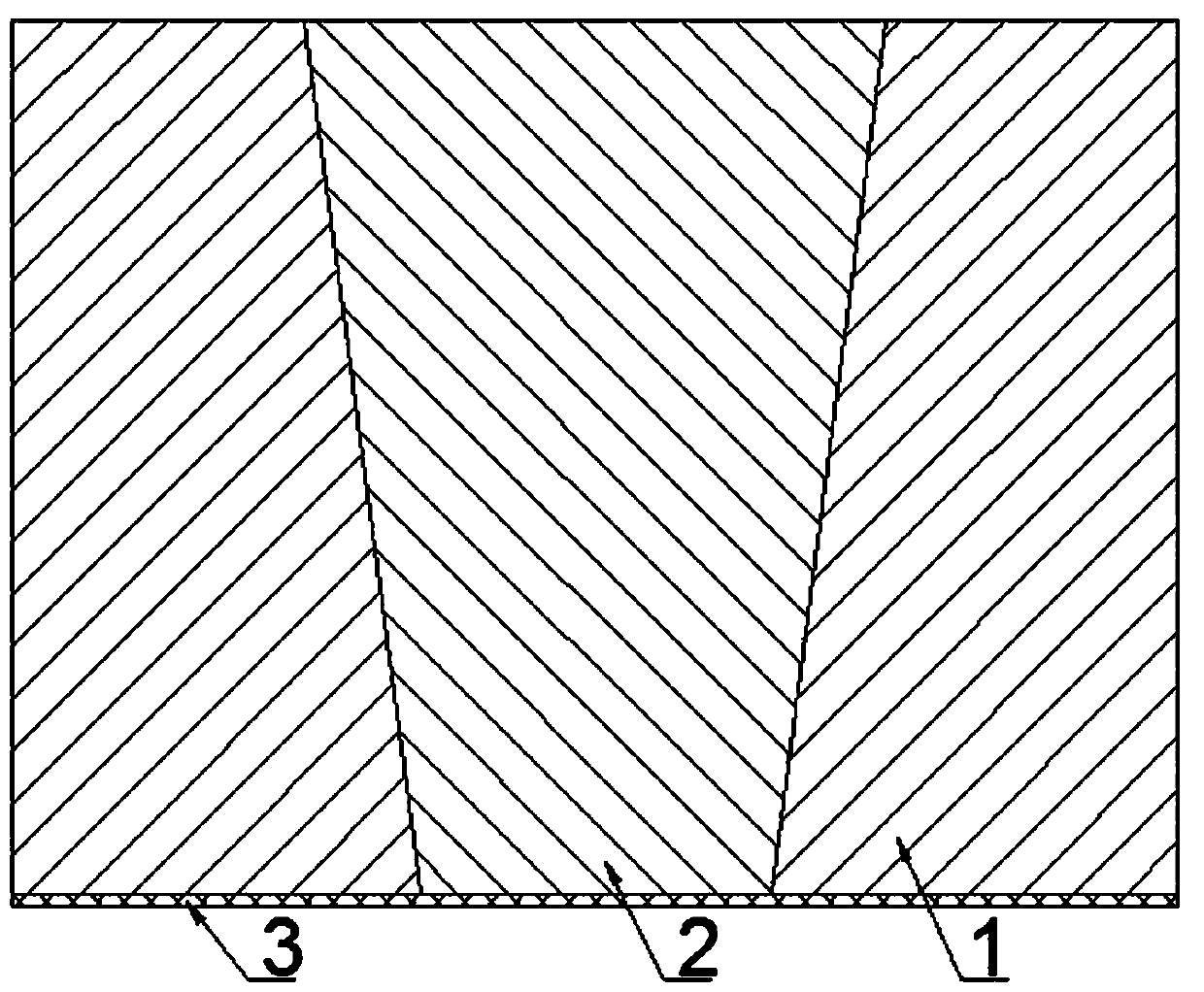

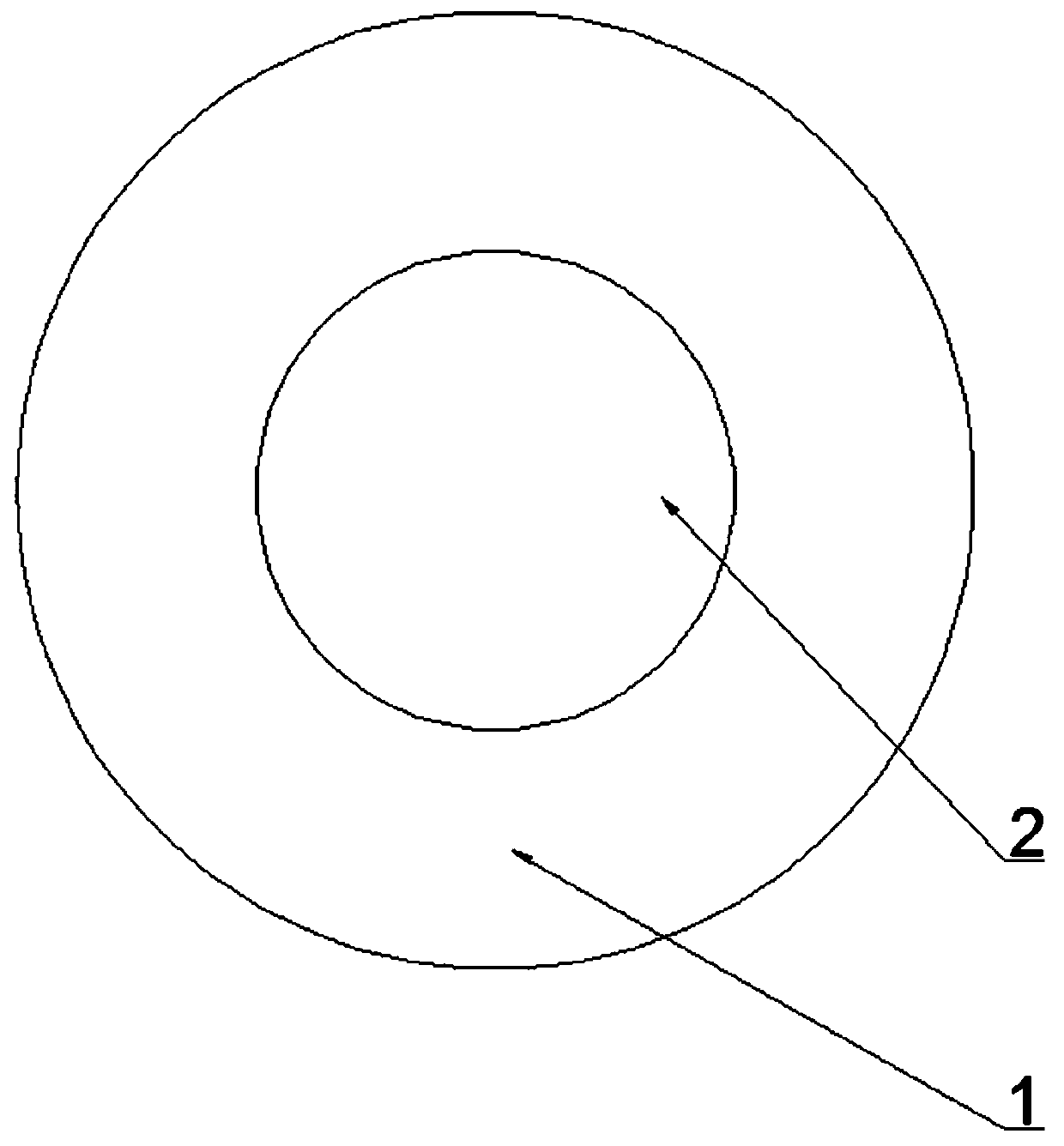

[0017] Such as figure 1 As shown, a dissolvable plug includes an outer ring 1 that can be dissolved quickly and a middle part 2 that dissolves at a low speed. The outer ring 1 is connected to the inner wall of the working tube. Dissolved barrier layer3. When it is necessary to remove the plug and connect the downhole with the uphole, you only need to pour a certain amount of water or other solutions into the tubing or working tube, and the water or other solutions will react with the plug, and the outer ring 1 will dissolve when the reaction occurs The speed is fast, and the dissolution rate of the middle part 2 is slow, so that the outer ring 1 will first form one or more through holes. Under the action of high-pressure oil and gas in the well, the outer ring 1 cannot maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com