Preparation method of aluminum alloy powder for additive manufacturing

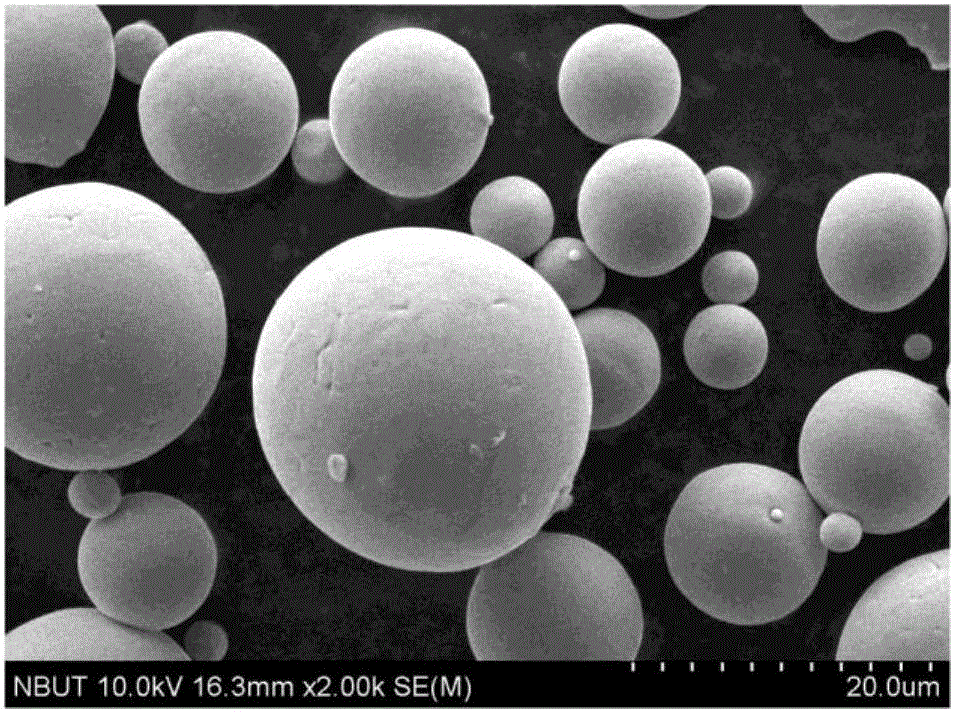

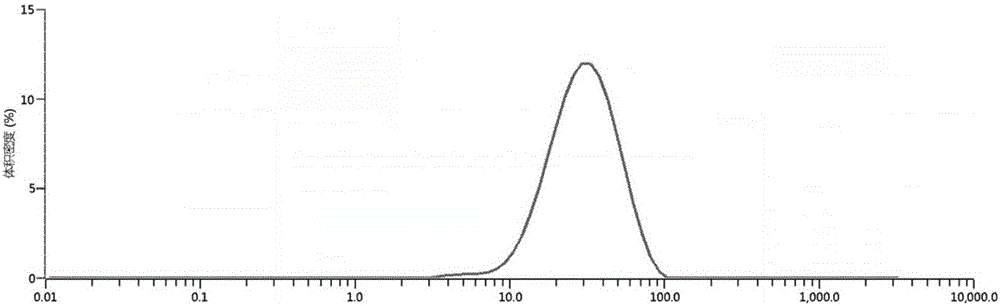

An additive manufacturing and aluminum alloy technology, applied in the field of 3D printing additive manufacturing, can solve the problems of complicated production process, low production efficiency and high production cost, and achieve the effect of good fluidity, low powder content and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

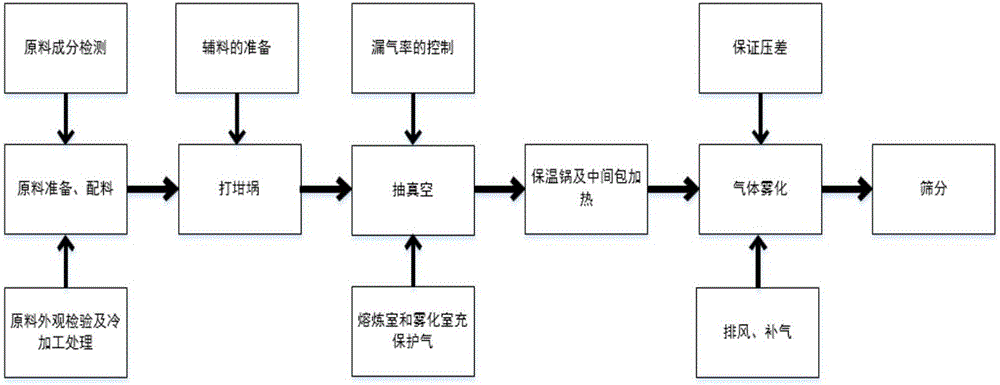

Method used

Image

Examples

Embodiment 1

[0031] (1) Use aluminum, silicon, magnesium, etc. as raw materials, and make ingredients according to the AlSi 10Mg alloy in ISO 3522-2007, wherein the purity of aluminum, silicon, and magnesium is ≥99.9%, and the oxygen content is ≤50ppm, so as to ensure that the surface of the raw material is free from trachoma, scarring, Defects such as inclusions.

[0032] (2) Install a heat-resistant plate at the bottom of the intermediate frequency induction coil, wrap the coil with high-temperature tape as a lining, put it into a graphite crucible, and fill the gap between the crucible and the coil with dried 20-200 mesh neutral sand to ensure that the gap must be gradually The layers are filled and compacted, and the upper part of the neutral sand is sealed with high-temperature asbestos, and then sealed with glass water mixed with alumina or zirconia powder. Graphite rods are added into the crucible to bake the crucible, and the baking temperature is controlled at 350°C.

[0033] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com