Method for processing micro-channels on surface of metal bipolar plate by adopting plate electrode in electrolytic transfer, as well as plate electrode thereof

A metal bipolar plate and flat electrode technology, used in electric machining equipment, electrochemical machining equipment, machining electrodes, etc., can solve the problem of being unsuitable for mass production, shorten the machining gap, ensure tight bonding, and smooth the flow field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

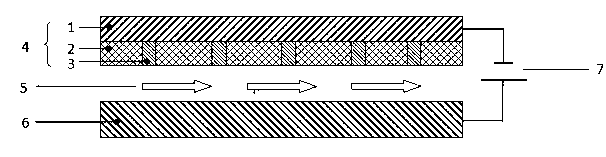

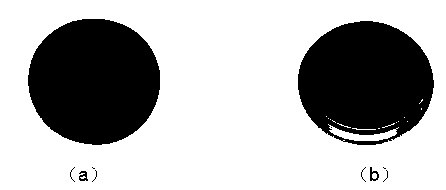

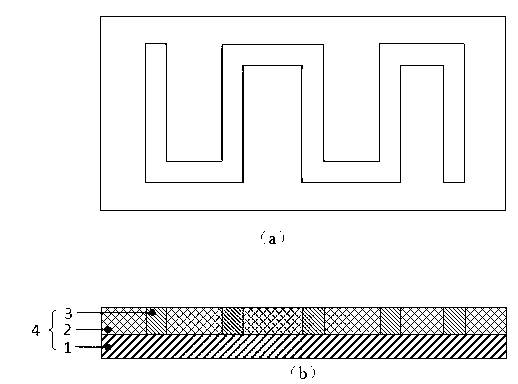

[0027] Combine below figure 1 , figure 2 and image 3 Specific description implements the present invention:

[0028] 1) The flat tool electrode (4) used in the method of electrolytically transferring the microfluidic channel on the surface of the metal bipolar plate by using the flat electrode is characterized in that: the flat tool electrode is used as the tool cathode in the electrolytic processing and consists of three parts , followed by photolithographic base metal (1), photoresist (2) and filling metal (3); the photolithographic base metal (1) is the carrier of photoresist, on the surface of photolithographic base metal (1) Coated with photoresist (2), the exposure light source (9) passes through the mask plate (9) to irradiate the photoresist for development, and the photoresist is engraved with a hollow flow channel, and then through the electroforming process, the The hollow runner is filled with filler metal (3);

[0029]2) Place the flat tool electrode (4) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com