Preparation method of titanium alloy powder for 3D printing

A 3D printing and titanium alloy technology, which is applied in the preparation of titanium alloy powder for 3D printing and the preparation of fine high-purity titanium alloy powder for 3D printing, to achieve the effects of increased production efficiency, low oxygen content, and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

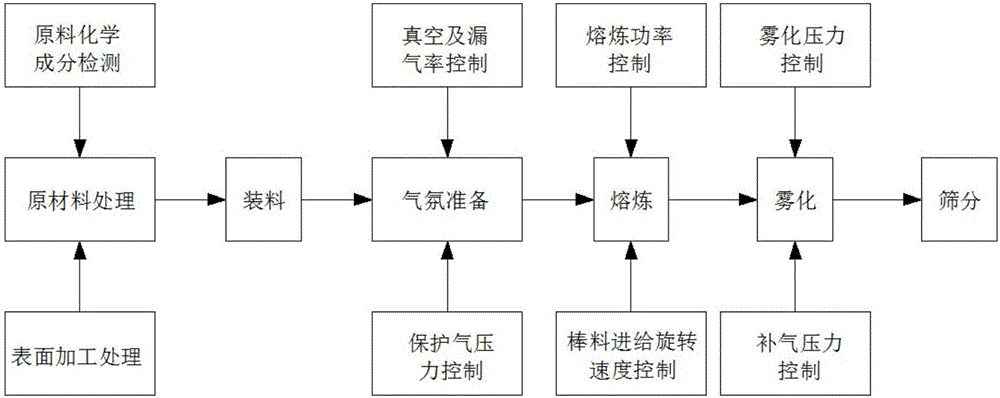

Method used

Image

Examples

Embodiment 1

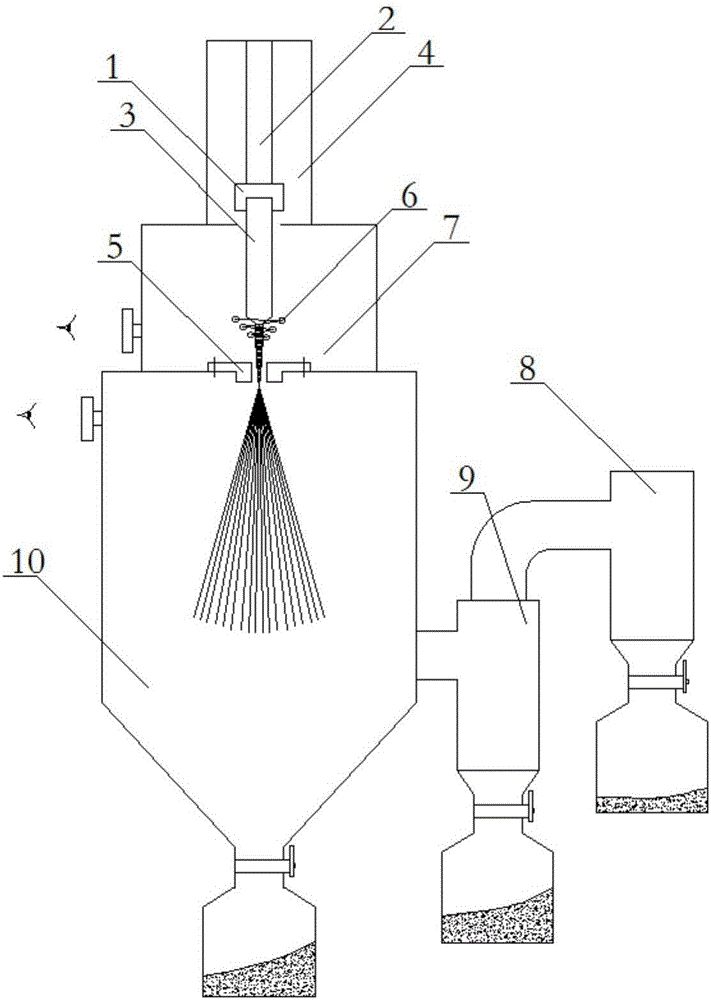

[0024] 1. Raw material processing: Select the TC4 bar for turning processing, the smooth surface makes the bar cylindricity reach 0.05mm, and one end is processed into a 120° cone angle;

[0025] 2. Loading and clamping: The bar is fixed to the lower end of the feeding mechanism through the clamping mechanism, and the feeding mechanism enables the bar to simultaneously generate axial linear feed and rotational motion; set the linear feed speed to 0.05m / min, The bar rotation speed is 600r / min;

[0026] 3. Preparation of smelting and atomizing atmosphere: pre-vacuum the smelting chamber and atomizing chamber, and the vacuum degree is required to be 1×10 ‐3 Pa, the leakage rate of the equipment is required to be less than 0.005Pa / s; high-purity argon gas is charged into the melting chamber and atomization chamber as protective gas, and the pressure of the melting chamber after being filled with high-purity argon gas is 0.1MPa, so as to avoid the ingredients in the melting process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com