Quickly vulcanized butyl rubber and preparation method and application thereof

A butyl rubber, rapid vulcanization technology, applied in the rubber field, can solve the problem of slow vulcanization speed of butyl rubber, and achieve the effects of high vulcanization speed, wide application and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

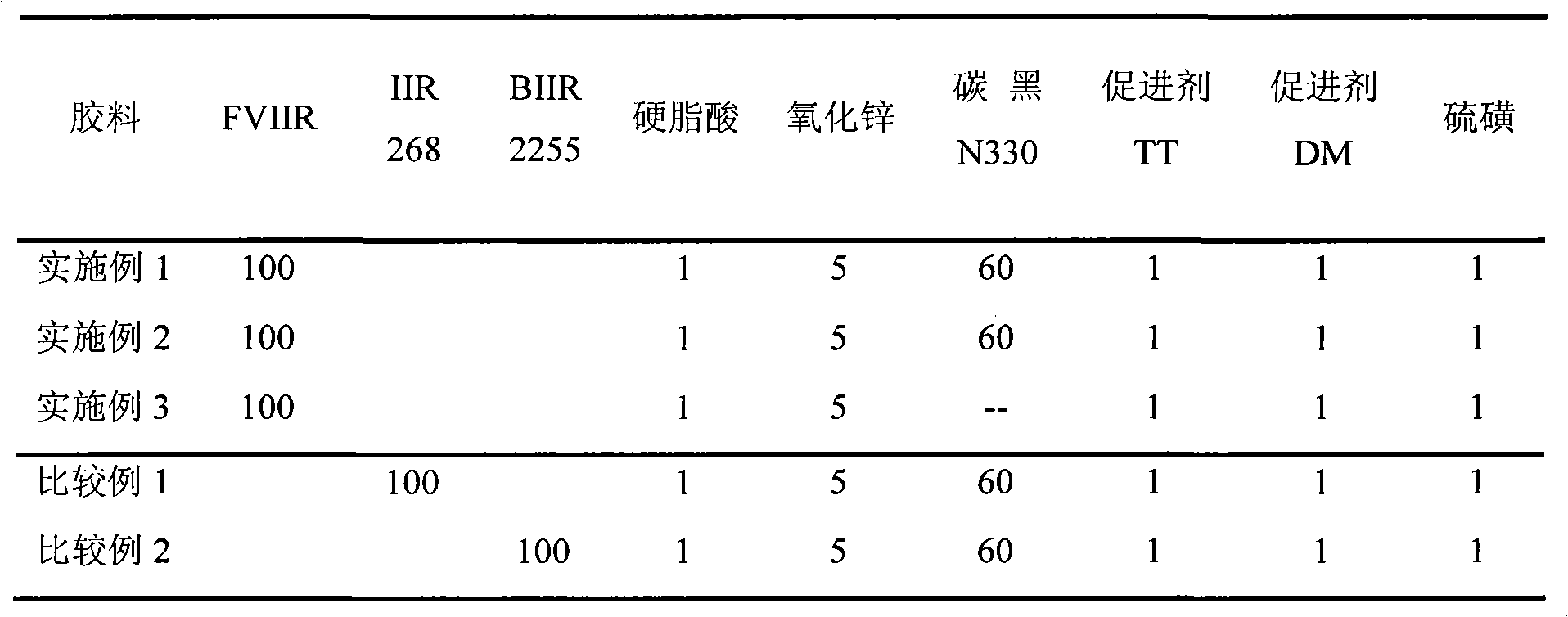

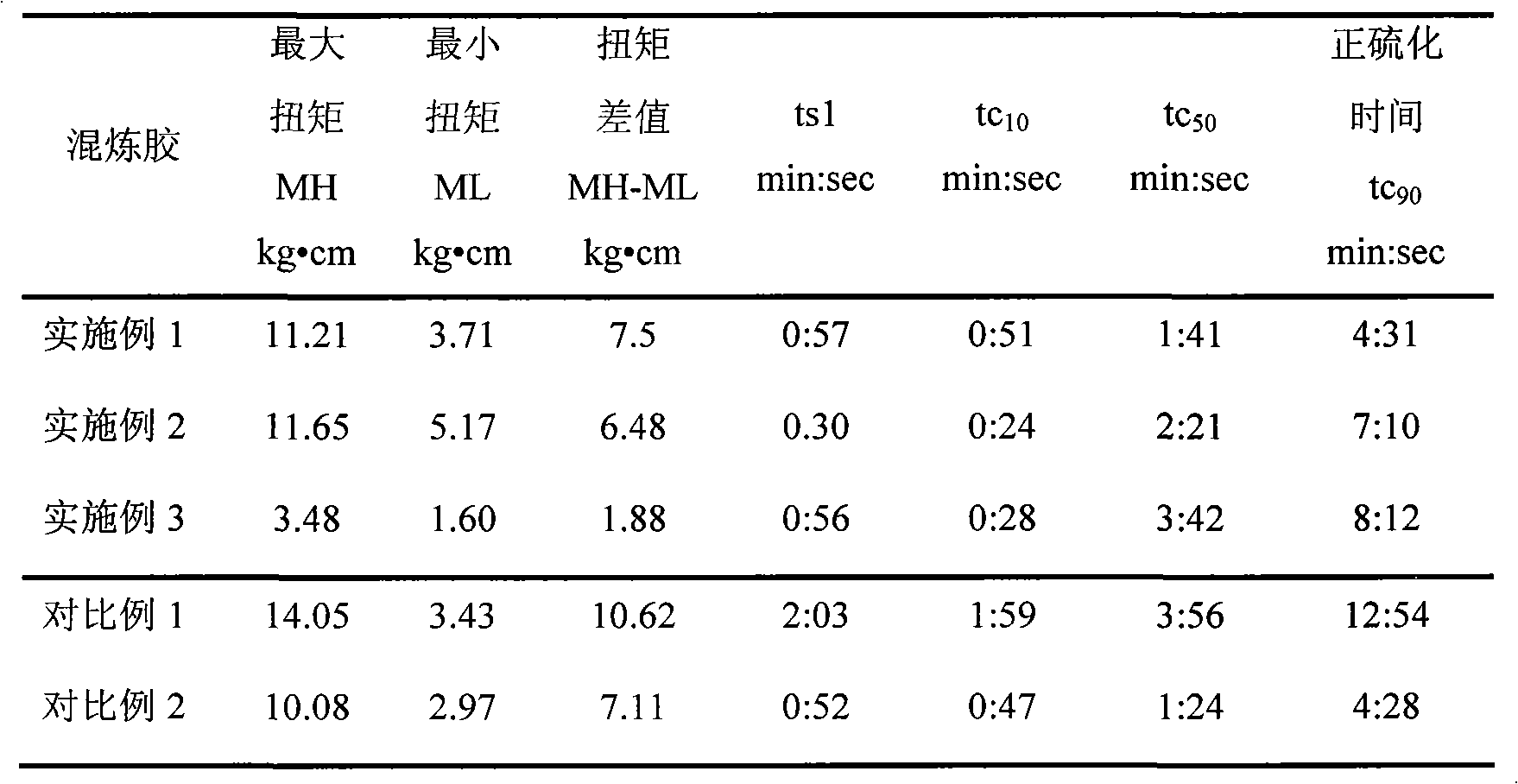

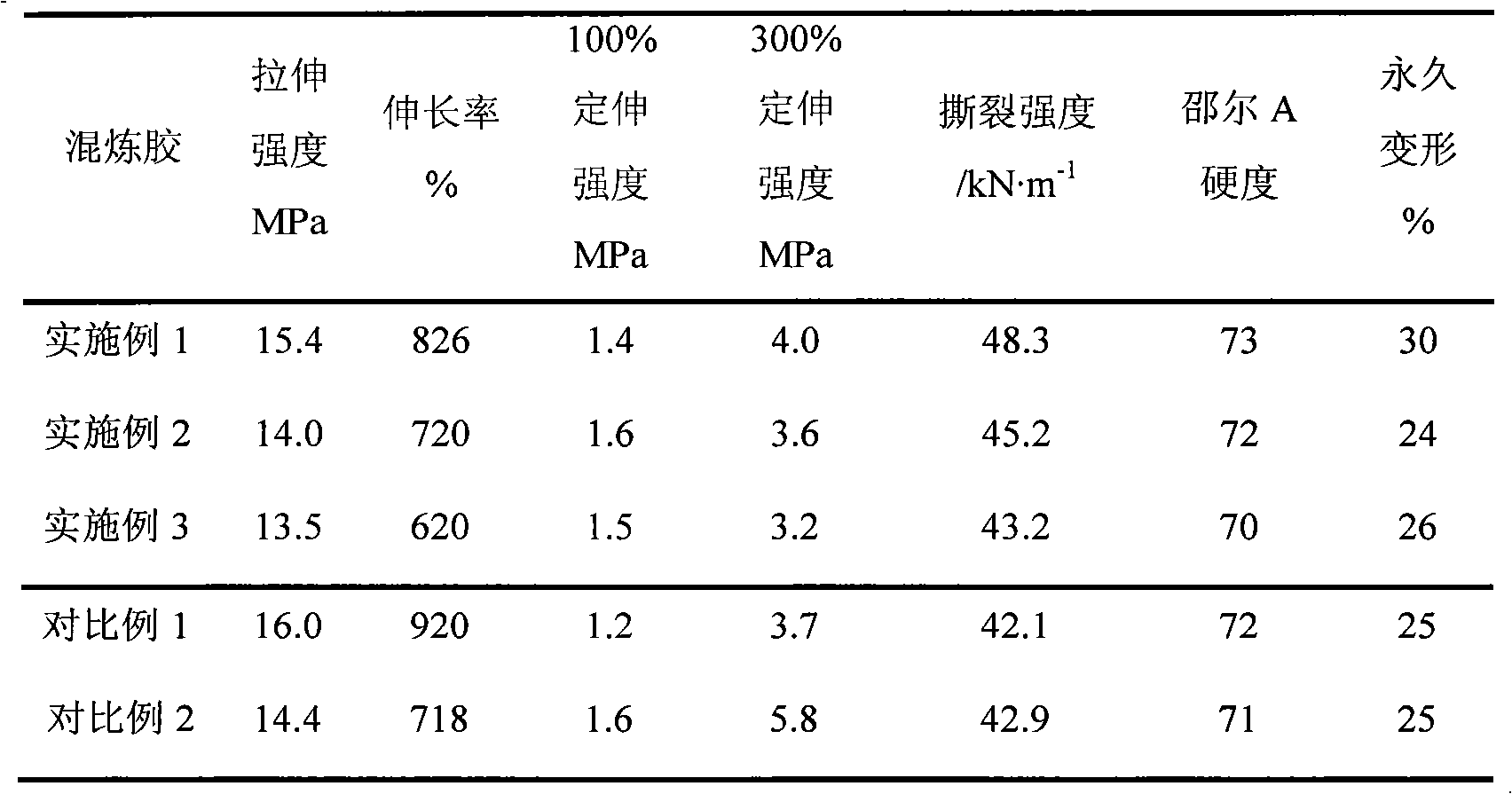

Examples

Embodiment 1

[0036] ①Modification treatment: Put 650g of butyl rubber (268, in which the content of isoprene chain is 1.70±0.2mol%) into the internal mixer, heat up to 80~100℃, and then add the modifier sodium hydride M 1 , Maleic anhydride M 2 Add to the internal mixer one by one, the added modifier is based on the weight of butyl rubber, M 1 1.6 copies, M 2 2 copies; M 1 The reaction time is 10min, the reaction temperature is 80~100℃, M 2 The reaction time is 15min, and the reaction temperature is 80~100℃

[0037] ②Reaction termination: add the terminator n-butanol (commercially available) in an amount of 10ml and add it to the rubber treated in step ① to terminate the modification reaction to obtain a fast vulcanized butyl rubber.

Embodiment 2

[0039] ① Modification treatment: Put 650g of butyl rubber (268, in which the content of isoprene chain is 1.70±0.2mol%) into an internal mixer, raise the temperature to 80~100℃, and then hydrogenate the modifier Sodium (NaBH 4 )M 1 , Maleic anhydride M 2 Add to the internal mixer one by one, the added modifier is based on the weight of butyl rubber, M 1 1.6 copies, M 2 2 copies; M 1 The reaction time is 10min, the reaction temperature is 80~100℃, M 2 The reaction time is 15min, and the reaction temperature is 80~100℃

[0040] ②Reaction termination: The terminator is tap water, the amount is 10ml, and it is added to the rubber treated in step ① to terminate the modification reaction to obtain a fast vulcanized butyl rubber.

Embodiment 3

[0042] ① Modification treatment: Put 50g of butyl rubber (268, in which the isoprene content is 1.70±0.2mol%) into the internal mixer, heat up to 80~100℃, and then add the modifier metal sodium M 1 , Cinnamaldehyde M 2 Add to the internal mixer one by one, the added modifier is based on the weight of butyl rubber, M 1 1.0 copies, M 2 1.3 copies; M 1 The reaction time is 10min, the reaction temperature is 80~100℃, M 2 The reaction time is 10min, and the reaction temperature is 80~100℃

[0043] ②Reaction termination: The terminator is tap water, the amount is 10ml, and it is added to the rubber treated in step ① to terminate the modification reaction to obtain a fast vulcanized butyl rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com