Graphite base and MOCVD equipment

A technology of graphite base and curved surface grooves, which is applied in chemical instruments and methods, gaseous chemical plating, crystal growth, etc., can solve problems such as instability, affecting the consistency of epitaxial wafers, and large viscous resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

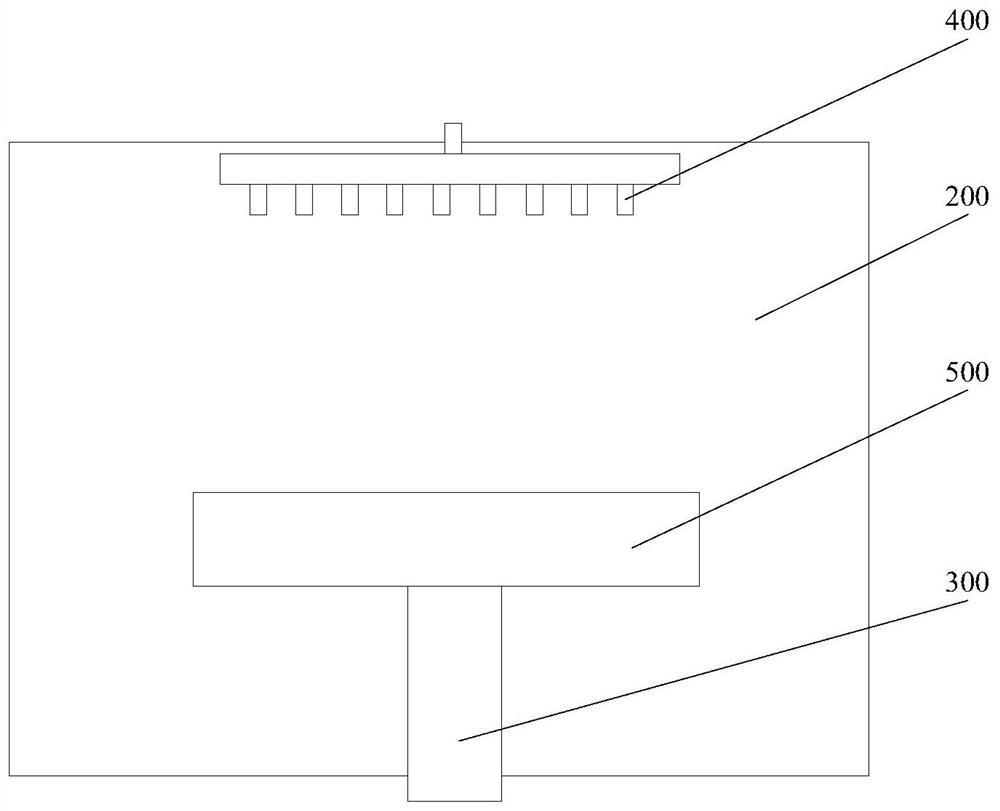

[0025] MOCVD equipment is currently a common equipment for epitaxial growth. figure 1 A schematic structural diagram of an MOCVD device provided by an embodiment of the present disclosure. see figure 1 , the MOCVD equipment includes a graphite base 500 , a reaction chamber 200 , a rotating shaft 300 and a gas outlet 400 . The graphite base 500 is arranged in the reaction chamber 200, the rotating shaft 300 is coaxially connected to the graphite base 500, the gas outlet 400 is installed on the wall of the reaction chamber 200, and the rotating shaft 300 and the gas outlet 400 are located on opposite sides of the graphite base 500. There are multiple gas outlets 400 , and the multiple gas outlets 400 are distributed at intervals an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com