Inorganic nano-particle surface grafted photoinitiator and application thereof

A technology of inorganic nanoparticles and photoinitiators, which is applied in the field of photocurable composite materials, can solve the problems of harsh reaction conditions of photoinitiators, uncommon experimental methods, and difficult reactions, and achieve excellent ultraviolet absorption capacity, enhanced mechanical properties, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of inorganic nanoparticle surface graft type photoinitiator, structural formula is as follows:

[0042]

[0043] Prepared by the following method:

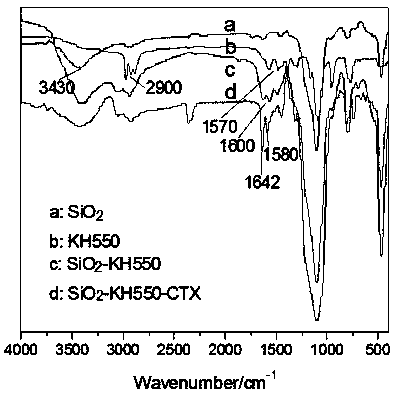

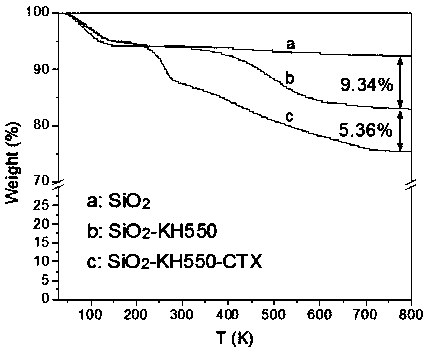

[0044] S1. Surface modification of nano-silica with silane coupling agent KH550: Add 240 mL of absolute ethanol, 60 mL of deionized water, and 5 g of nano-silica to a 500 mL three-neck flask, ultrasonically shake for 30 min, and transfer to the oil Equipped with a mechanical stirring paddle, a thermometer, and a condenser tube, add 5 g of KH550 dropwise after heating up to 60 °C, and react for 6 h. After the reaction, through centrifugation—washing—recentrifugation—vacuum drying—grinding, KH550 surface-modified nano-SiO 2 powder;

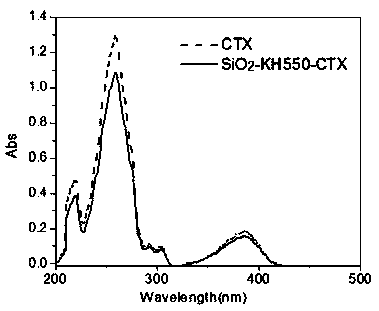

[0045] S2. Modified nano-SiO 2 Grafting photoinitiator CTX: Add 300 mL xylene and 5 g of the modified nano-SiO to a 500 mL three-neck flask 2 , ultrasonically oscillated for 30 min, and moved to an oil bath, equipped with a mechanical stirring paddle, a thermometer, and a condenser ...

Embodiment 2

[0053] A kind of inorganic nanoparticle surface graft type photoinitiator, structural formula is as follows:

[0054]

[0055] Prepared by the following method:

[0056] S1. Surface modification of nano-silica with silane coupling agent KH560: Add 240 mL of absolute ethanol, 60 mL of deionized water, and 5 g of nano-silica to a 500 mL three-neck flask, ultrasonically shake for 30 min, and transfer to the oil Equipped with a mechanical stirring paddle, a thermometer, and a condenser tube, add 5 g of KH560 dropwise after heating up to 60 °C, and react for 6 h. After the reaction, through centrifugation—washing—recentrifugation—vacuum drying—grinding, KH560 surface-modified nano-SiO 2 powder;

[0057] S2. Modified nano-SiO 2 Grafting photoinitiator CTX: Add 300 mL xylene and 5 g of the above-mentioned modified nano-SiO to a 500 mL three-neck flask 2 , ultrasonically oscillated for 30 min, and moved to an oil bath, equipped with a mechanical stirring paddle, a thermometer, ...

Embodiment 3

[0059] A kind of inorganic nano particle surface graft type photoinitiator, is prepared by following method:

[0060] S1. Surface modification of nano-silica by silane coupling agent 3-aminopropyltris(methoxyethoxyethoxy)silane: add 200 mL of absolute ethanol and 80 mL of dehydrated Ionized water and 3 g of nano-silica, ultrasonically oscillated for 50 min, moved to an oil bath, equipped with a mechanical stirring paddle, a thermometer, and a condenser tube, and added 6 g of 3-aminopropyltri(methoxyl) dropwise after heating up to 70°C Ethoxyethoxy) silane, reaction 4h. After the reaction, through centrifugation—washing—recentrifugation—vacuum drying—grinding, 3-aminopropyltris(methoxyethoxyethoxy)silane surface-modified nano-SiO 2 powder;

[0061] S2. Modified nano-SiO 2 Grafting photoinitiator CTX: Add 200 mL xylene and 3 g of the above-mentioned modified nano-SiO to a 500 mL three-neck flask 2 , ultrasonically oscillated for 40 min, and moved to an oil bath, equipped wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com