Production process of small micellae water

A small molecular mass water and production process technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of ineffective removal of raw water, etc., achieve strong activity and simple process flow Highly efficient and beneficial to metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

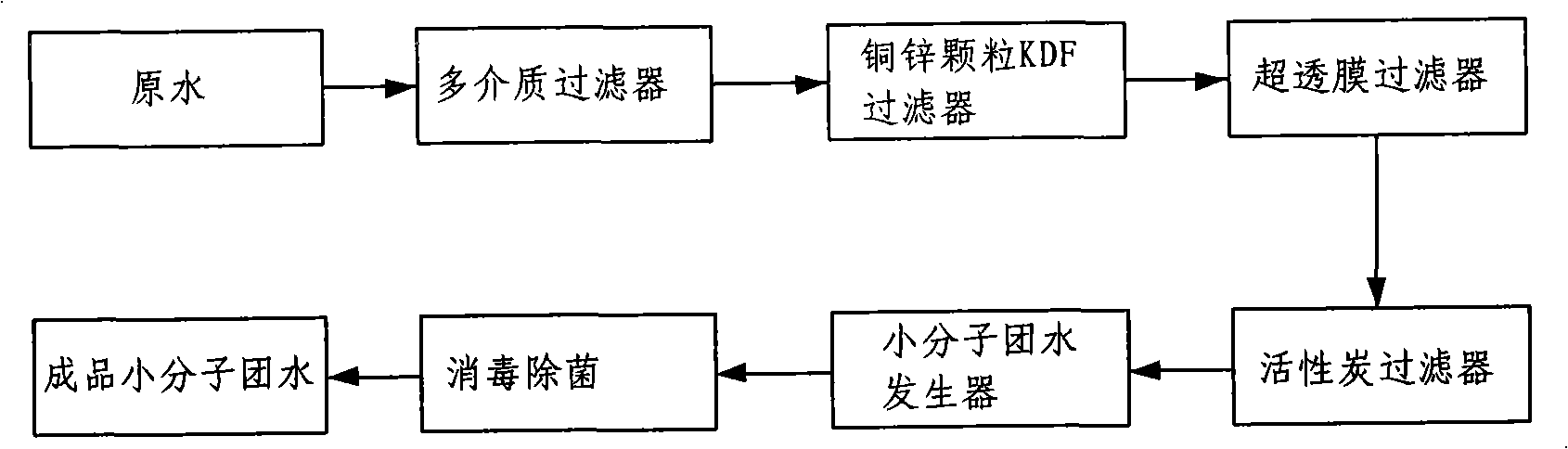

[0022] Accompanying drawing is the technological process schematic diagram of the present invention, as shown in the figure:

[0023] A production process of small molecular cluster water, comprising the following steps:

[0024] a. Use urban tap water or natural mineral water or pure water as raw water, and filter through multi-stage filters to filter out large particles of impurities visible to the naked eye;

[0025] b. Pass the water treated in step (a) through KDF of copper-zinc particles, and undergo microelectrochemical oxidation-reduction treatment to remove harmful substances such as chlorine and water-soluble lead, mercury, nickel, chromium and other soluble metals in the water.

[0026] c. The water treated in step (b) is passed through an ultrafiltration membrane filter with a filter pore diameter less than 0.01 μm to filter out bacteria, viruses, colloids, iron rust and other impurities in the water;

[0027] d. filter the water treated with step (c) with activat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com