Production method of high-adsorptivity melt-blow non-woven fabrics

A melt-blown non-woven fabric and production method technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve problems such as affecting the filtration capacity of non-woven fabrics, activated carbon adsorption capacity, increasing non-woven fabric filtration resistance, blocking activated carbon voids, etc. Achieve the effect of ensuring purification efficiency and adsorption capacity, avoiding desorption and eliminating secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

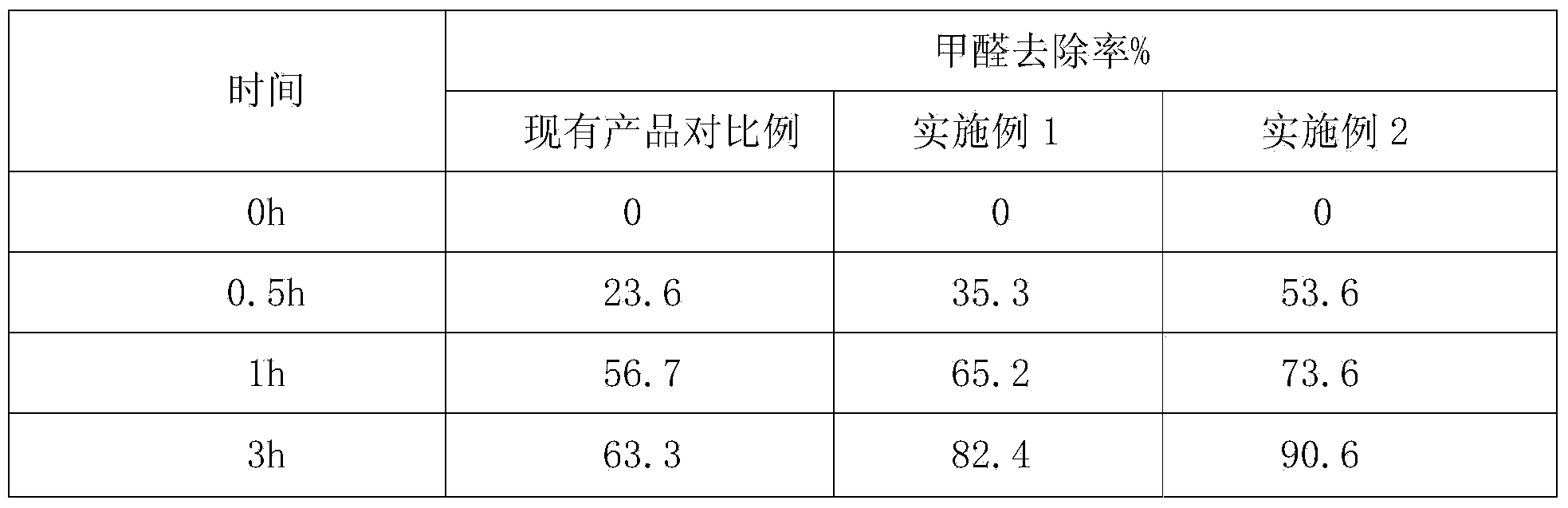

Embodiment 1

[0024] A production method of highly absorbent melt-blown non-woven fabric, comprising the following production steps:

[0025] (1) Stir and mix the formaldehyde-removing particles and activated carbon particles with a mass ratio of 25:75 to obtain an additive material, wherein the formaldehyde-removing particles are composed of permanganate with a mass ratio of 1:0.05:0.7:1.5:0.8:3 Potassium, platinum powder, manganese acetate, sodium hydroxide, activated alumina and titanium dioxide;

[0026] (2) Mix and stir the polypropylene pellets, stearic acid and penetrant T for non-woven fabrics with a mass ratio of 25:0.6:0.4, and then melt-spin them by melt-blowing method, and form a web Pre-pressed polypropylene pellets: the ratio of the additive material in the step (1) is 25:0.6, and after the additive material in the step (1) is mixed evenly, the high-adsorptive melting powder described in the present invention is obtained by using air flow or mechanical forming. Spray non-wove...

Embodiment 2

[0028] A production method of highly absorbent melt-blown non-woven fabric, comprising the following production steps:

[0029] (1) Stir and mix the formaldehyde-removing particles and activated carbon particles with a mass ratio of 75:25 to obtain an additive material, wherein the formaldehyde-removing particles are composed of permanganate with a mass ratio of 1:0.01:0.5:1:0.5:2 Potassium, platinum powder, manganese acetate, sodium hydroxide, activated alumina and titanium dioxide;

[0030] (2) Mix polyethylene pellets for non-woven fabrics with a mass ratio of 25:0.15:0.25, fatty alcohol polyoxyethylene ether sodium sulfate (AES), and propylene glycol alginate and mix evenly, and then, through the melt blown method It is melt-spun and mixed with the additive material in step (1) according to the ratio of polyethylene pellets: additive material ratio of 25:1.5 in step (1) before forming a net, and then formed into a net by air flow or mechanically The highly absorbent melt-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com