Advanced treatment process for chemical industry park wastewater

A chemical industry park and advanced treatment technology, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, aerobic process treatment, etc., can solve the problems of failing to meet discharge standards and difficult biochemical degradation of wastewater, and achieve good SS and inorganic phosphorus Removal effect, reduction of operating costs, and improvement of COD removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

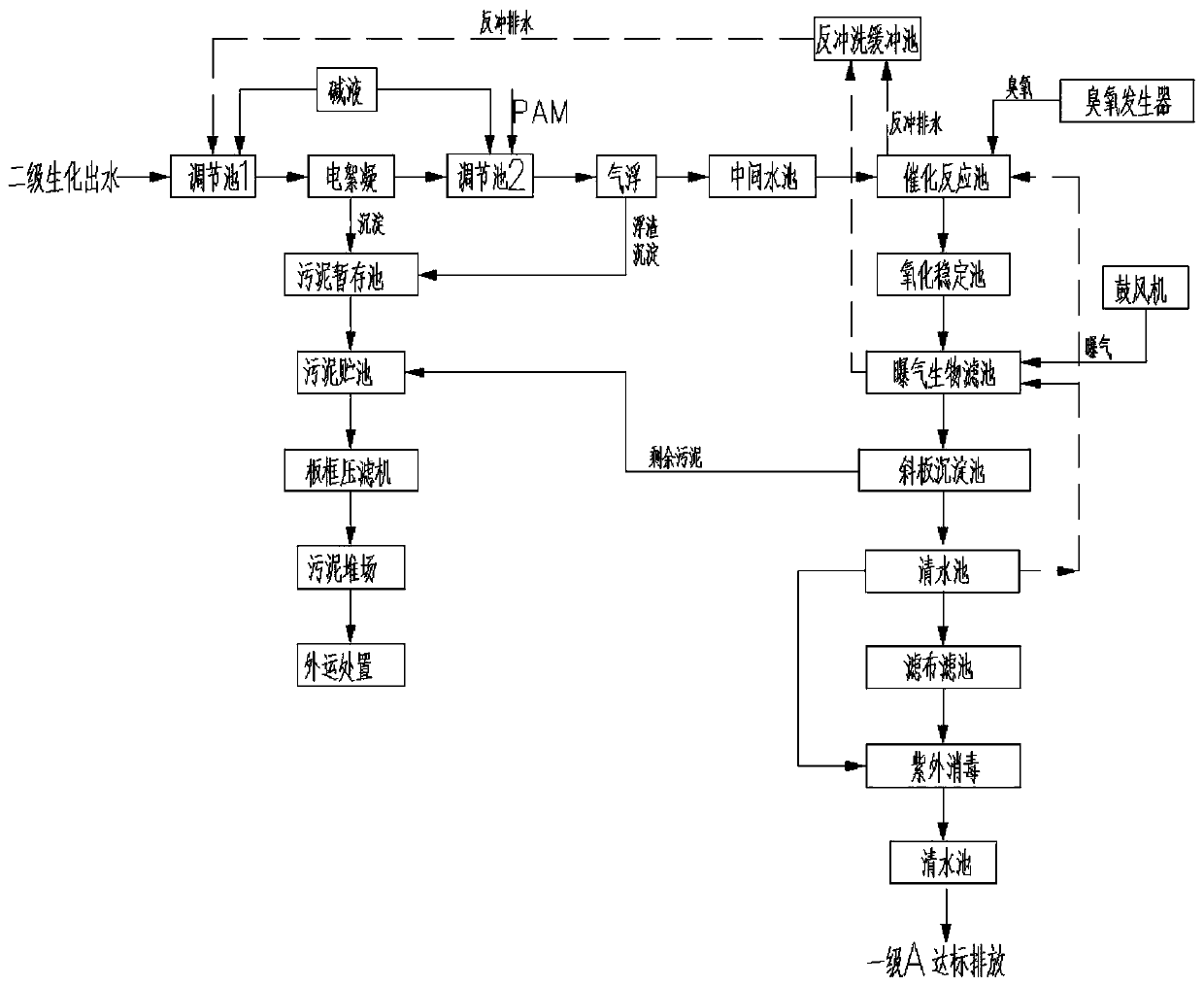

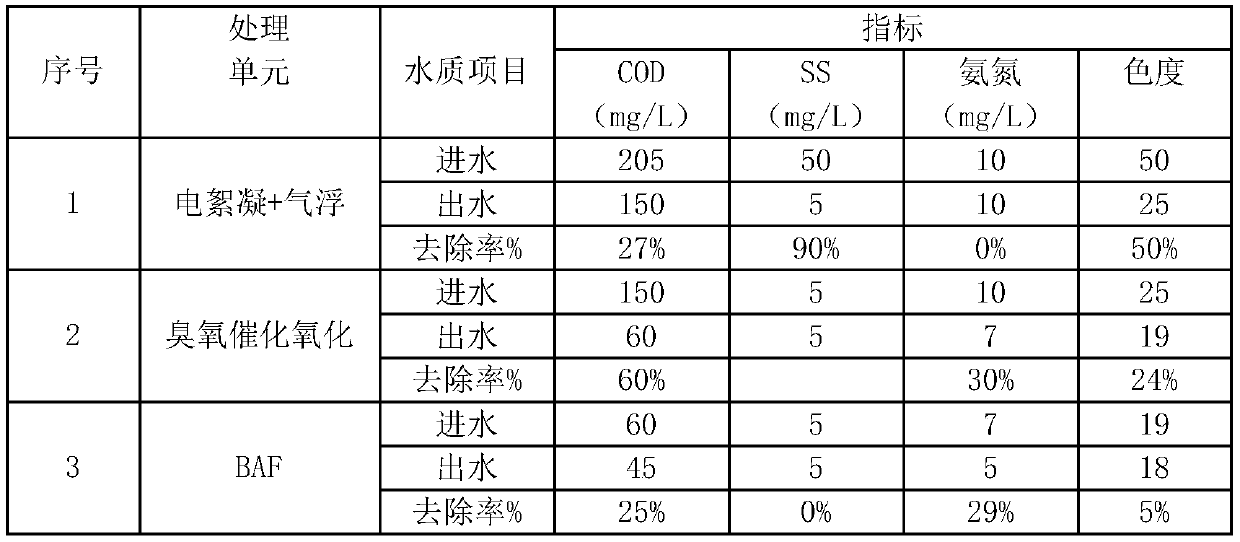

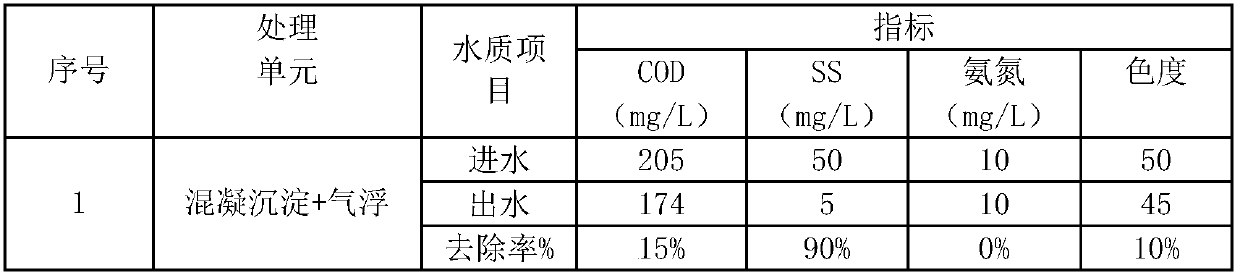

[0051] like figure 1 The wastewater in a chemical park shown in the figure flows through the regulating tank, the electroflocculation system, the air flotation system, the intermediate tank, the ozone catalytic reaction tower, the oxidation stabilization tank, the aerated biological filter, the inclined plate sedimentation tank, and the clean water after the secondary biochemical treatment. Pool, filter cloth filter, ultraviolet disinfection pool, carry out advanced treatment, and then discharge to the first-level A emission standard.

[0052] First, the secondary biochemical effluent enters the conditioning tank 1, and the liquid caustic soda is stored in the liquid caustic storage tank. It is added to the conditioning tank 1 through the liquid alkali dosing pump 1, and an agitator is installed in the conditioning tank 1 to achieve sufficient liquid alkali and wastewater. Mixing, the pH meter 1 is set in the adjustment tank 1, the pH value signal is input to the controller, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com