Solid amine interpenetrating network porous amino resin and its preparation method and use

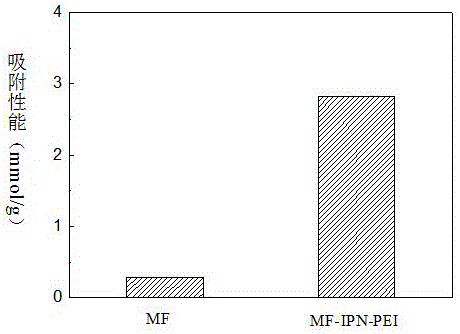

A technology of interpenetrating network and amino resin, which is applied in the field of solid amine interpenetrating network porous amino resin and its preparation, can solve the problems of inability to realize physical and chemical synergistic adsorption and low swelling of porous materials, and achieve synergistic adsorption and preparation The effect of adsorption capacity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Prepare solid amine interpenetrating network porous amino resin, the steps are as follows:

[0039] (1) Take 18mmol of melamine and 45mmol of paraformaldehyde, and add the two to 20ml of a mixed solution of dimethyl sulfoxide (DMSO) and water (wherein DMSO and H 2 The volume ratio of O is 3:1), forming a melamine formaldehyde solution with a total monomer concentration of 3.15mmol / ml, heating up to 80°C and stirring to dissolve. When the solution is clear, continue stirring for 1 h to obtain a prepolymer of melamine and formaldehyde, cool to room temperature, and set aside.

[0040] (2) Dissolve 1.4g of acrylamide in 5ml of water, stir and reflux at 45°C for 10 minutes to obtain an acrylamide prepolymer, cool to room temperature for later use; pour the acrylamide prepolymer into the prepolymer of melamine and formaldehyde, and then Add a certain amount of hydrochloric acid to adjust its pH to 6, stir evenly, transfer to a reaction kettle, heat up to 140°C for hydrot...

Embodiment 2

[0047] 1. Prepare solid amine interpenetrating network porous amino resin, the steps are as follows:

[0048] (1) Take 12mmol of melamine and 30mmol of paraformaldehyde, and add the two to 20ml of a mixed solution of dimethyl sulfoxide (DMSO) and water (wherein DMSO and H 2 The volume ratio of O is 3:1), forming a melamine-formaldehyde solution with a total monomer concentration of 2.1 mmol / ml, heating up to 90°C and stirring to dissolve. When the solution is clear, continue stirring for 1 h to obtain a prepolymer of melamine and formaldehyde, cool to room temperature, and set aside.

[0049] (2) Dissolve 1.0g of acrylamide in 5ml of water, stir and reflux at 65°C for 30 minutes to obtain an acrylamide prepolymer, cool to room temperature for later use; pour the acrylamide prepolymer into the prepolymer of melamine and formaldehyde, and then Add a certain amount of hydrochloric acid to adjust its pH to 6.5, stir evenly, move it into a reaction kettle, heat up to 140°C and hea...

Embodiment 3

[0053] 1. Prepare solid amine interpenetrating network porous amino resin, the steps are as follows:

[0054] (1) Take 16mmol of melamine and 40mmol of paraformaldehyde, and add the two to 20ml of a mixed solution of dimethyl sulfoxide (DMSO) and water (wherein DMSO and H 2 The volume ratio of O is 3:1), forming a melamine-formaldehyde solution with a total monomer concentration of 2.8mmol / ml, heating up to 90°C and stirring to dissolve. When the solution is clear, continue stirring for 1 h to obtain a prepolymer of melamine and formaldehyde, cool to room temperature, and set aside.

[0055] (2) Dissolve 1.8g of acrylamide in 5ml of water, stir and reflux at 55°C for 60 minutes to obtain an acrylamide prepolymer, cool to room temperature for later use; pour the acrylamide prepolymer into the prepolymer of melamine and formaldehyde, and then Add a certain amount of hydrochloric acid to adjust its pH to 7.0, stir evenly, then transfer to a reaction kettle, heat up to 140°C and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com