Chitosan grafted polylactic acid copolymer, and preparation method and application thereof

A polylactic acid copolymer and chitosan technology, applied in the field of degradable biomass materials, can solve the problems of low grafting rate, high catalyst dosage, long time consumption, etc., and achieve low dosage, excellent solubility, and short polymerization time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

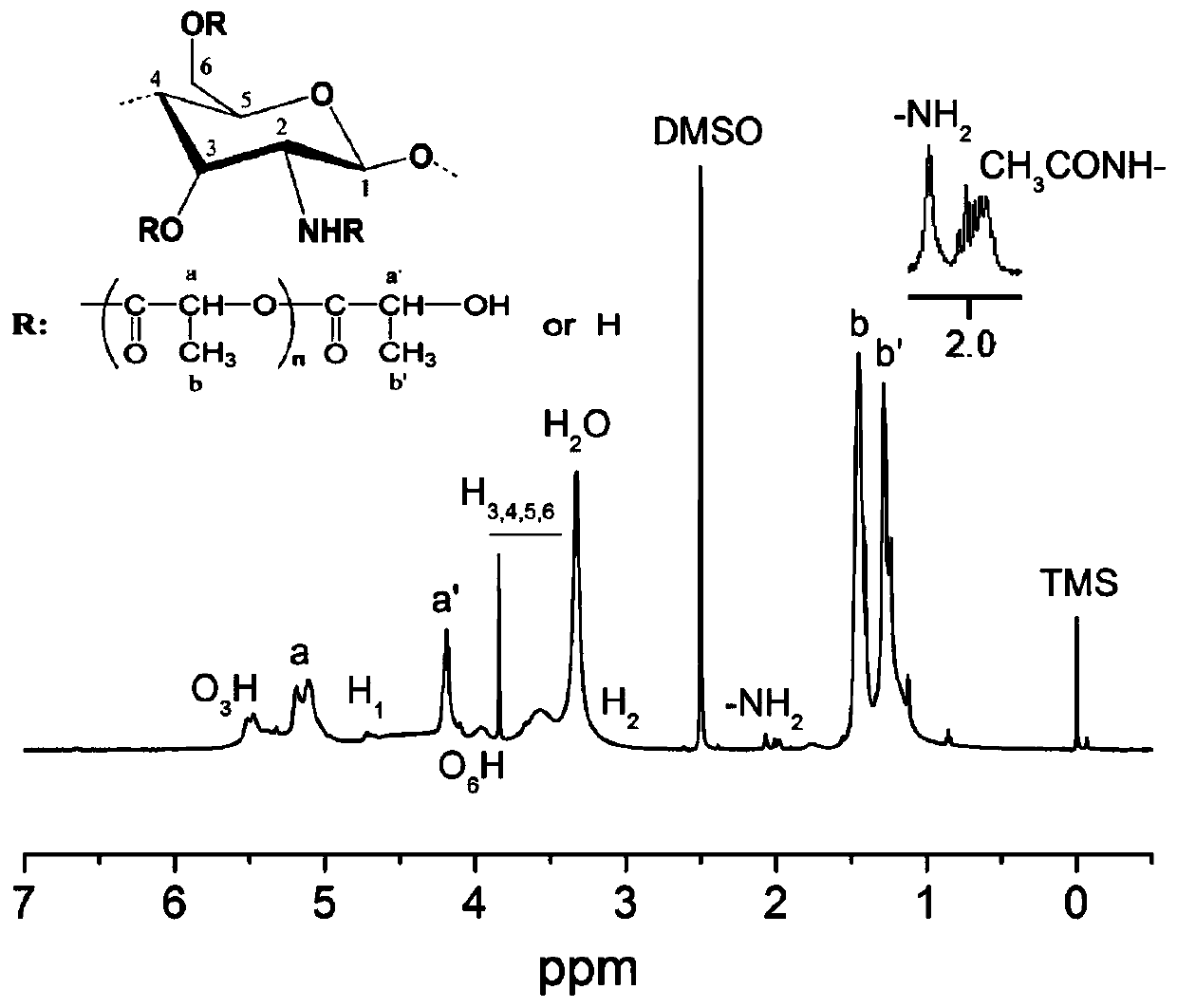

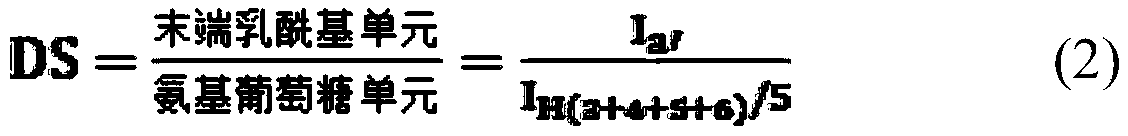

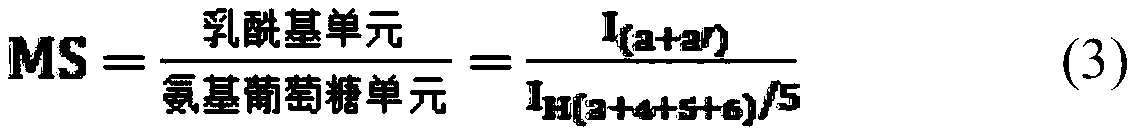

[0032] 0.2g chitosan and 4g EMIMAc were put into a dry 50ml three-necked flask, vacuumed three times with nitrogen; the temperature was raised to 100°C, and vigorously stirred for 3h under a nitrogen atmosphere to obtain a homogeneous solution; subsequently, the solution was cooled to At room temperature, slowly add 7.072g D,L-lactide monomer (the molar ratio of D,L-lactide monomer: glucosamine unit in chitosan is 40:1) and 0.0354g DMAP; then repeat Vacuum, nitrogen-filled nitrogen pumping process three times. The temperature was raised to 100°C, and vigorously stirred for 5 hours under a nitrogen atmosphere to obtain a reaction solution; after the reaction solution was cooled to room temperature, the copolymer was precipitated by adding 10 times the volume of the reaction solution in absolute ethanol; finally, purified by acetone extraction Copolymer for 24 hours, remove D,L-lactide monomer self-polymerized, PDLLA homopolymer not grafted on chitosan; dry the purified copolyme...

Embodiment 2

[0041] Put 0.2g chitosan and 4g EMIMAc into a dry 50ml three-necked flask, vacuum three times with nitrogen; raise the temperature to 100°C, stir vigorously under nitrogen atmosphere for 3h to obtain a homogeneous solution. Subsequently, the solution was cooled to room temperature, and 1.768 g of D, L-lactide monomer was slowly added (the molar ratio of D, L-lactide monomer: glucosamine unit in chitosan = 10:1) and 0.0088g DMAP. The evacuated, nitrogen-filled nitrogen pumping process was then repeated three times. The temperature was raised to 100°C, and vigorously stirred for 5 hours under a nitrogen atmosphere to obtain a reaction solution; after the reaction solution was cooled to room temperature, the copolymer was precipitated by adding 10 times the volume of the reaction solution in absolute ethanol; finally, purified by acetone extraction Copolymer for 24 hours, remove D,L-lactide monomer self-polymerized, PDLLA homopolymer not grafted on chitosan; dry the purified cop...

Embodiment 3

[0045]0.2g chitosan and 4g EMIMAc were put into a dry 50ml three-necked flask, vacuumed three times with nitrogen; the temperature was raised to 100°C, and vigorously stirred for 3h under a nitrogen atmosphere to obtain a homogeneous solution; subsequently, the solution was cooled to At room temperature, 3.536g of D,L-lactide monomer (the molar ratio of D,L-lactide monomer:glucosamine unit in chitosan is 20:1) and 0.0177g of DMAP were slowly added. The evacuated, nitrogen-filled nitrogen pumping process was then repeated three times. The temperature was raised to 100°C, and vigorously stirred for 5 hours under a nitrogen atmosphere to obtain a reaction solution; after the reaction solution was cooled to room temperature, the copolymer was precipitated by adding 10 times the volume of the reaction solution in absolute ethanol; finally, purified by acetone extraction Copolymer for 24 hours, remove D,L-lactide monomer self-polymerized, PDLLA homopolymer not grafted on chitosan; d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com