Preparation method of PET non-woven fabric with photocatalytic degradation function

A non-woven fabric and photocatalytic technology, which is applied in the direction of chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., to increase the amount of grafting and improve hydrophilicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

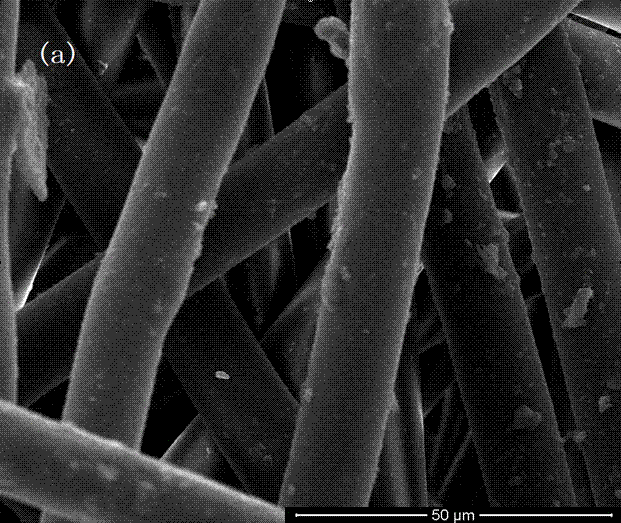

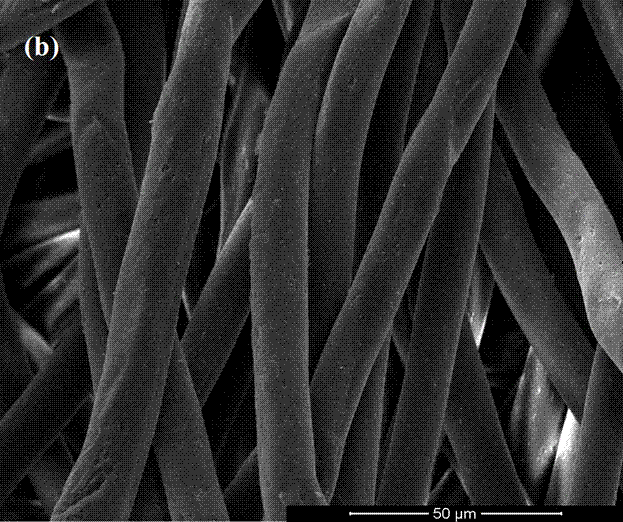

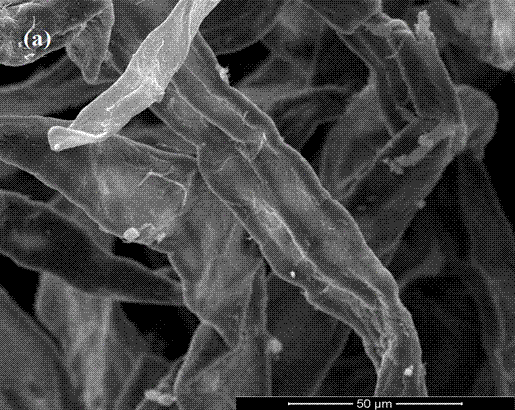

Image

Examples

Embodiment 1

[0060] This embodiment focuses on analyzing the influence of alkali etching time on titanium dioxide grafting.

[0061] The uniqueness of this embodiment is that the second step, the third step and the fourth step are respectively carried out by using 5 groups of PET non-woven fabrics. The 5 groups of PET non-woven fabrics are group 1-5 respectively; the alkali etching time of the PET non-woven fabrics of the 1st, 2nd, 3rd, 4th and 5th groups is 1, 2, 3, 4, 5 hours (that is, the first group 1 hour, group N for N hours, group 5 for 5 hours). The first step, the third step and the fourth step of the five groups of PET non-woven fabrics are operated in the same way.

[0062] In this embodiment, each group of PET non-woven fabrics was dried and weighed before and after the titanium dioxide grafting step, so as to calculate the grafting rate of titanium dioxide. In this embodiment, except for the alkali etching time, other parameters (such as time parameters and temperature param...

Embodiment 2

[0069] This embodiment focuses on the analysis of the influence of the concentration of tetrabutyl titanate on the grafting ratio of titanium dioxide in the fourth step, that is, the grafting step of titanium dioxide.

[0070]In this example, 6 groups of PET non-woven fabrics were used for the fourth step reaction (the first to third steps were the same), and the 6 groups of PET non-woven fabrics were grafted with titanium dioxide under different tetrabutyl titanate concentrations. They are the PET non-woven fabrics of the 6th-11th group respectively.

[0071] In the tetrabutyl titanate solution used in the titanium dioxide grafting step, the corresponding relationship between the volume ratio of tetrabutyl titanate and water and the PET non-woven fabric samples of groups 6-11 is:

[0072] The volume ratio of tetrabutyl titanate to water corresponding to the sixth group of PET non-woven fabrics is 1:100;

[0073] The volume ratio of tetrabutyl titanate to water corresponding ...

Embodiment 3

[0085] This embodiment focuses on analyzing the influence of whether acrylic acid is used on the grafting rate of titanium dioxide in the third step, that is, the nanometer wood cellulose grafting step.

[0086] In this embodiment, four groups of PET non-woven fabrics are used for the reaction, which are the 12th to 15th groups of PET non-woven fabrics. For each group of PET non-woven fabrics, a cellulose homogeneous acrylic acid solution was prepared separately, and the third step reaction was carried out respectively.

[0087] In this embodiment, the operations of the first step, the second step and the fourth step are the same. In this example, the volume ratio of tetrabutyl titanate to water in the fourth step is 5:100. In each step, unless otherwise specified in this example, other parameters (such as time parameters and temperature parameters) are Use the preferred value.

[0088] The concentration of nano-wood fibers in the cellulose homogeneous acrylic solution corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com