Surface modification method of macroporous polystyrene resin for blood purification and blood purifier

A polystyrene resin and blood purification technology, which is applied in chemical instruments and methods, suction instruments, medicine instruments, etc. The effect of high efficiency and easy mass industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Put 50g of polystyrene macroporous adsorption resin in a plastic bag or a glass container, and leave a certain volume of space on the top of the resin to retain enough oxygen. The resin was irradiated under γ-rays with a dose of 10 kGy. The irradiated resin now forms a large number of peroxides on the surface, and the peroxides can be used as free radical initiators to initiate the polymerization and grafting reactions of monomers.

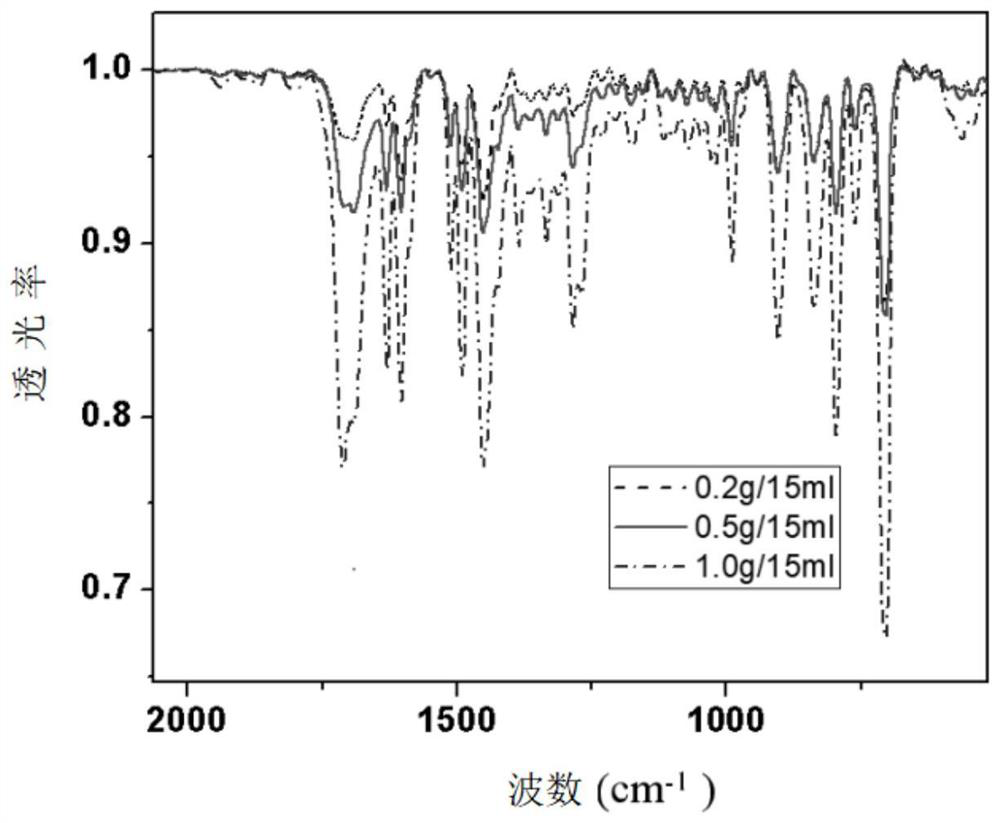

[0032] In 15 mL of isopropanol, take 1.0 g of the above-mentioned polystyrene resin and 0.5 g of hydroxyethyl methacrylate (HEMA), put them into a three-necked flask, and under the protection of nitrogen, adjust the temperature of the water bath to 80 ° C, and react for 4 h under stirring. After rinsing with a large amount of ethanol, it is dried to obtain a HEMA-grafted polystyrene macroporous adsorption resin.

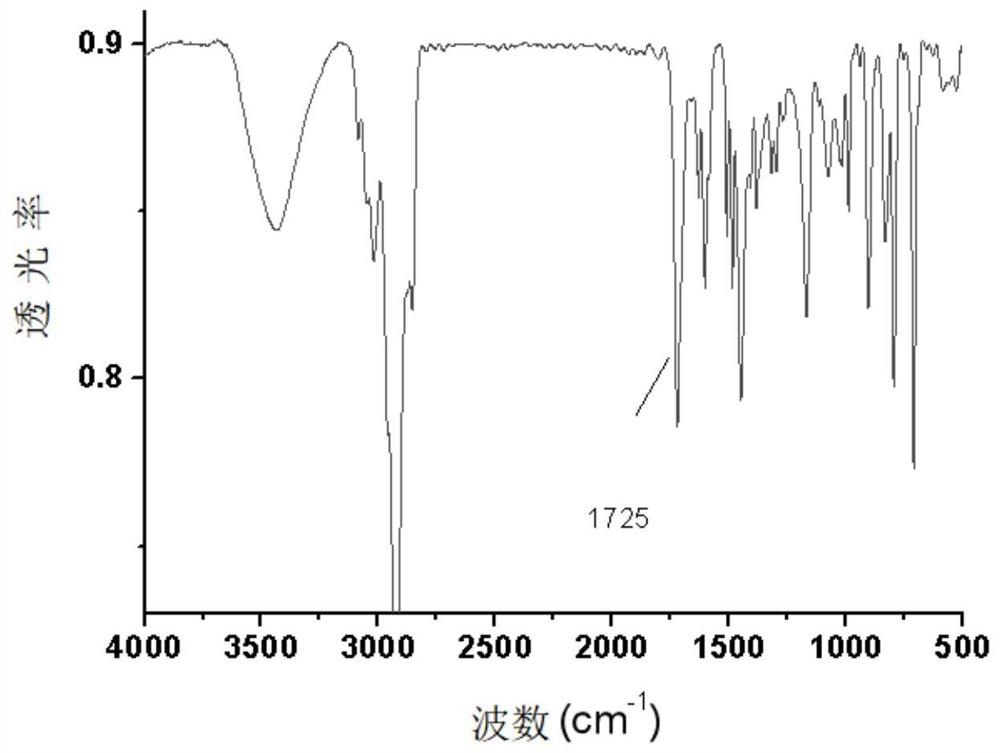

[0033] from figure 1 It can be seen that the resin after HEMA grafting is at 1725cm -1 The C=O stretching vibration peak appe...

Embodiment 2

[0035] In 15 mL of isopropanol, take 1.0 g of the irradiated polystyrene resin and 0.1 g of HEMA in Example 1, put them into a three-necked flask, and under the protection of nitrogen, adjust the temperature of the water bath to 80 ° C, and react for 4 h under stirring. After rinsing with a large amount of ethanol, it is dried to obtain a HEMA-grafted polystyrene macroporous adsorption resin.

Embodiment 3

[0037] In 15 mL of water, take 1.0 g of the irradiated polystyrene resin and 0.5 g of HEMA in Example 1, put them into a three-necked flask, and under the protection of nitrogen, adjust the temperature of the water bath to 80°C and react for 6 h under stirring. After washing, dry to obtain HEMA-grafted polystyrene macroporous adsorption resin.

[0038] The adsorption properties of the HEMA-grafted polystyrene macroporous adsorption resins obtained in Examples 1 to 3 are shown in Table 1 below.

[0039] The BET adsorption performance of the HEMA grafted resin of table 1 embodiment 1 to 3

[0040]

[0041] From the data in Table 1, it can be seen that the specific surface area of the resin generally decreases with the increase of the grafting amount, the average pore volume gradually decreases, and the average pore diameter fluctuates slightly. Due to the small amount of grafting, the specific surface area and average pore volume change range is small, which will not serio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com