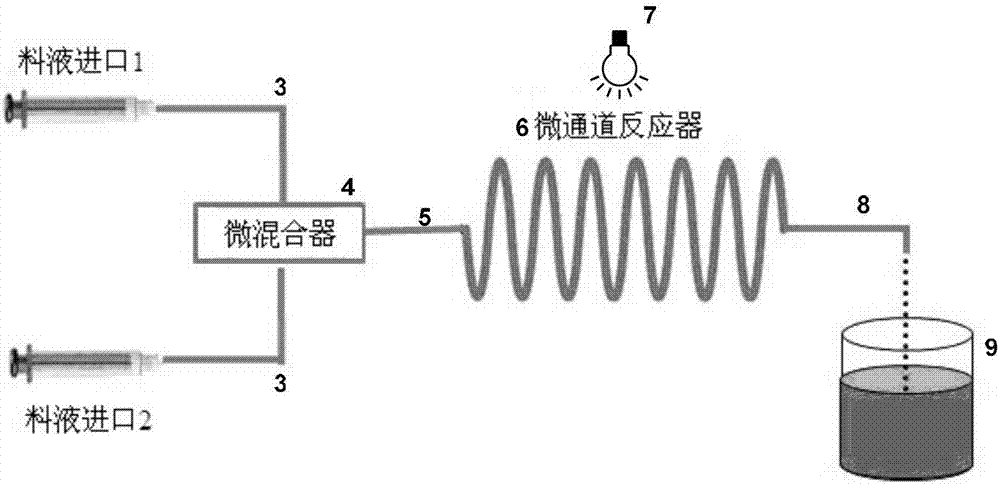

Microfluidic photoinduction polymer modification method

A light-induced, polymer technology, applied in the field of microfluidic light-induced polymer modification, can solve the problems of slow polymerization reaction speed and large metal residue, and achieve fast reaction speed, reduced metal residue, and precise and controllable polymerization reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

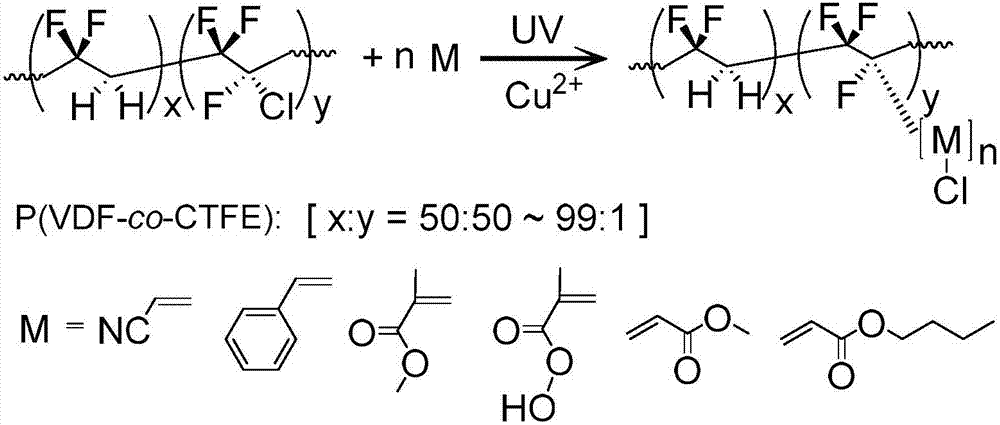

Embodiment 1

[0035] At room temperature, take 6% P(VDF-co-CTFE) (1.0g, 0.89mmol), copper chloride (19mg, 0.111mmol), dimethyl sulfoxide (15mL) and mix well under nitrogen atmosphere to obtain a homogeneous Phase solution A; the Me 6 -TREN (44.55μl, 0.167mmol), hydroxyethyl methacrylate (3.22mL, 26.7mmol) and dimethyl sulfoxide (15mL) were mixed uniformly under a nitrogen atmosphere to obtain a homogeneous solution B; The phase solutions were pumped into the micro-mixer through the Y-shaped mixing valve at the same time, and the flow rate of the two pumps was controlled to be 0.042mL / min. After being fully mixed in the micro-mixer, 400nm ultraviolet light (9W, 1.2mW / cm 2 ) irradiated microchannel reactor, while using compressed air to maintain the ambient temperature of the microchannel reactor is 20 ℃, the flow rate of the mixed system in the microchannel reactor is 0.083mL / min, and the retention time is 60min; Liquid, use a mixture of methanol and water (V / V=1:1) as a precipitant to prec...

Embodiment 2

[0037] At room temperature, take 9% P(VDF-co-CTFE) (1.0g, 0.89mmol), copper chloride (4.8mg, 0.028mmol), dimethyl sulfoxide (15mL) and mix well under nitrogen atmosphere to obtain Homogeneous solution A; cyclam-β (33.45mg, 0.167mmol), butyl acrylate (3.83mL, 26.7mmol) and dimethyl sulfoxide (15mL) were mixed uniformly under nitrogen atmosphere to obtain homogeneous solution B; The above two homogeneous solutions were simultaneously pumped into the micro-mixer through the Y-shaped mixing valve, and the flow rate of the two pumps was controlled to be 0.083mL / min. After being fully mixed in the micro-mixer, 380nm ultraviolet light (9W, 1.2mW / cm 2 ) irradiated microchannel reactor, while using compressed air to maintain the ambient temperature of the microchannel reactor is 20 ℃, the flow rate of the mixed system in the microchannel reactor is 0.167mL / min, and the retention time is 30min; Liquid, use a mixture of methanol and water (V / V=1:1) as a precipitant to precipitate and col...

Embodiment 3

[0039]At room temperature, take 50% P(VDF-co-CTFE) (1.0g, 0.89mmol), copper chloride (4.8mg, 0.028mmol), dimethyl sulfoxide (15mL) and mix well under nitrogen atmosphere to obtain Homogeneous solution A; TPMA (48.49mg, 0.167mmol), styrene (3.07mL, 26.7mmol) and dimethyl sulfoxide (15mL) were mixed uniformly under nitrogen atmosphere to obtain homogeneous solution B; the above two The homogeneous solution was pumped into the micro-mixer through the Y-type mixing valve at the same time, and the flow rate of the two pumps was controlled to be 0.083mL / min. After being fully mixed in the micro-mixer, 365nm ultraviolet light (18W, 2.1mW / cm 2 ) irradiated microchannel reactor, while using compressed air to maintain the ambient temperature of the microchannel reactor is 30 ℃, the flow rate of the mixed system in the microchannel reactor is 0.167mL / min, and the retention time is 30min; Liquid, use a mixture of methanol and water (V / V=1:1) as a precipitant to precipitate and collect the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com