Preparation method of nano-silica surface grafted hydroxyl terminated polybutadiene rubber

A technology of hydroxyl-terminated polybutadiene and nano-silica, which is applied in the treatment of dyed low-molecular organic compounds, dyed high-molecular organic compounds, and fibrous fillers. It can solve the problem of low grafting amount and achieve enhanced mechanical properties. Performance, simple reaction synthesis process, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

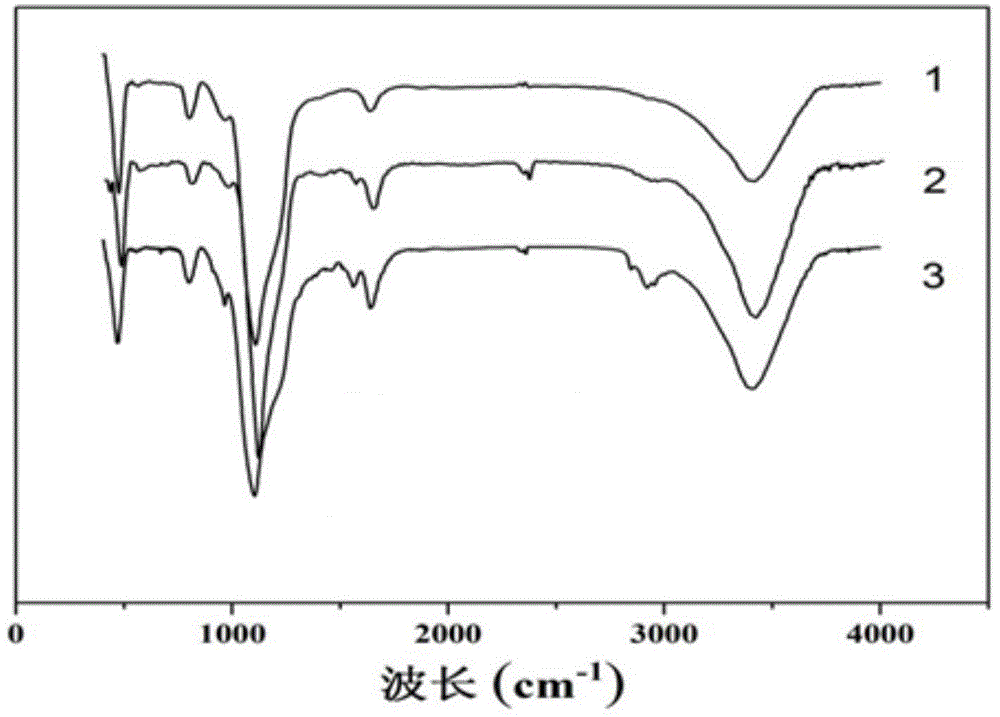

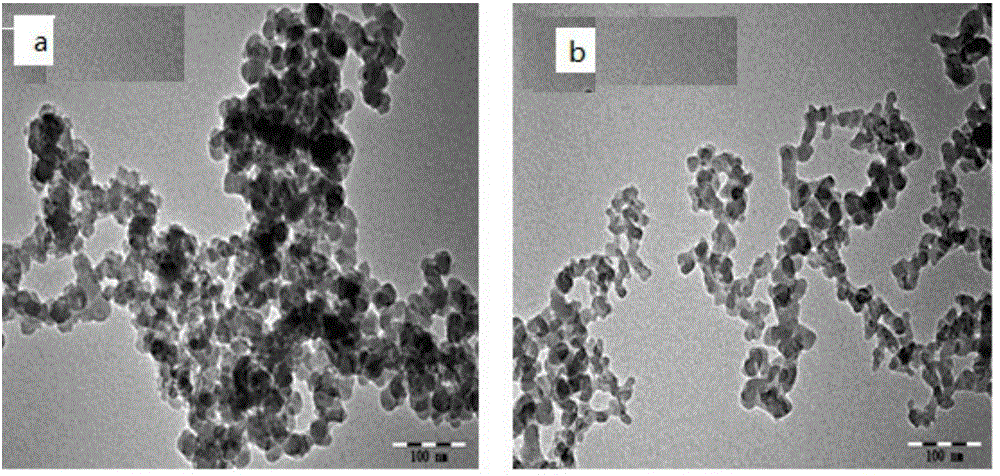

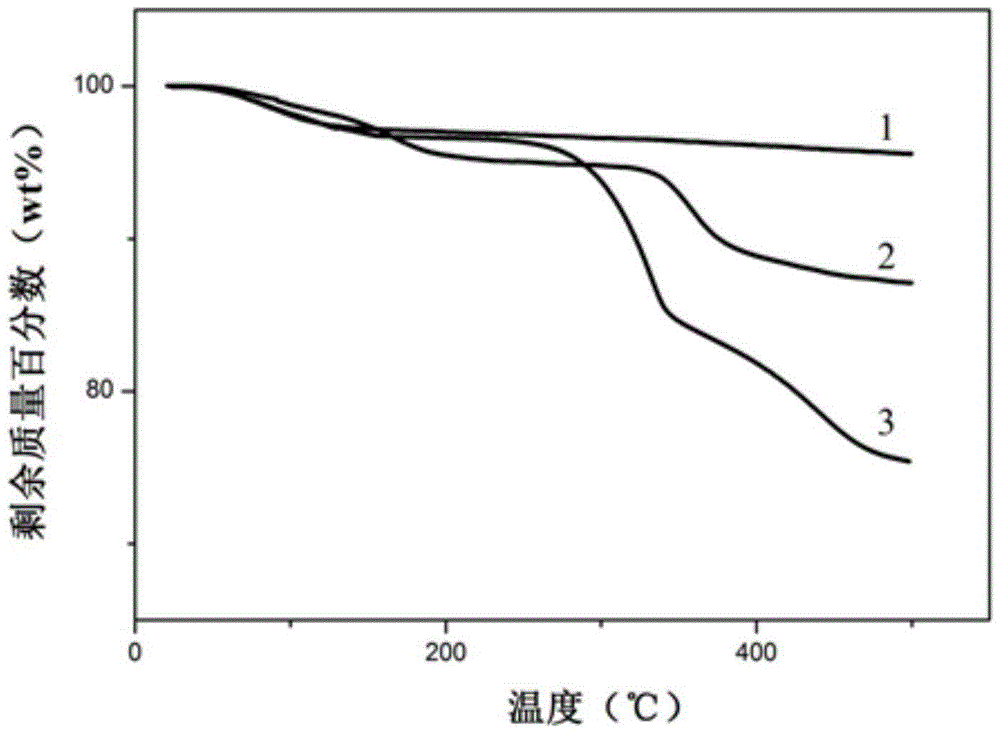

[0021] 1) Synthesis of isocyanate-terminated nano-silica: first clean and activate the nano-silica, take 5 g of the activated nano-silica and put it into a 250 ml three-necked flask equipped with a stirring bar and a reflux condenser, then add 150 ml of acetone solution , ultrasonic dispersion for 30 minutes. Under an inert atmosphere, slowly drop a mixed solution containing 0.005g of the catalyst dibutyltin dilaurate and 5g of isophorone diisocyanate, react at 50°C for 6 hours, collect by centrifugation, and use acetone to ultrasonically disperse and wash and centrifuge three times to obtain Nano silica with isocyanate groups on the surface;

[0022] (2) Synthesis of modified nano-silica on the surface of hydroxyl-terminated polybutadiene rubber: get 5 g of nano-silica with isocyanate groups on the surface synthesized in (2) and pack into 250 ml with stirring Then add 150ml of butyl acetate solution to the three-necked flask with the reflux condenser, and ultrasonically disp...

Embodiment 2

[0025] (1) Synthesis of isocyanate-terminated nano-silica: first clean and activate the nano-silica, take 5g of the activated nano-silica and put it into a 250ml three-necked flask equipped with a stirring bar and a reflux condenser, then add 150ml of acetone solution, ultrasonically dispersed for 40 minutes. Under an inert atmosphere, slowly drop a mixed solution containing 0.03 g of the catalyst stannous octoate and 10 g of isophorone diisocyanate, react at 60 ° C for 5 hours, collect by centrifugation, and use acetone to ultrasonically disperse and wash and centrifuge four times to obtain the surface Nano silica containing isocyanate groups;

[0026] (2) Synthesis of modified nano-silica on the surface of hydroxyl-terminated polybutadiene rubber: get 5 g of nano-silica with isocyanate groups on the surface synthesized in (2) and pack into 250 ml with stirring Then add 150ml of butyl acetate solution to the three-necked flask with the reflux condenser, and ultrasonically di...

Embodiment 3

[0028] (1) Synthesis of isocyanate-terminated nano-silica: first clean and activate the nano-silica, take 5g of the activated nano-silica and put it into a 250ml three-necked flask equipped with a stirring bar and a reflux condenser, then add 150ml of acetone solution, ultrasonically dispersed for 50 minutes. Under an inert atmosphere, slowly drop a mixed solution containing 0.1 g of catalyst bis(dodecylsulfur) dibutyltin and 15 g of isophorone diisocyanate, react at 80°C for 3 hours, collect by centrifugation, and disperse with acetone ultrasonically Wash and centrifuge five times to obtain nano-silica containing isocyanate groups on the surface;

[0029] (2) Synthesis of modified nano-silica on the surface of hydroxyl-terminated polybutadiene rubber: get 5 g of nano-silica with isocyanate groups on the surface synthesized in (2) and pack into 250 ml with stirring Then add 150ml of butyl acetate solution to the three-necked flask with the reflux condenser, and ultrasonically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com