Glass fiber mesh cloth latex and preparation method thereof

The technology of glass fiber and mesh cloth is applied in the field of glass fiber mesh cloth latex and its preparation, which can solve the problems of reduced bonding strength between coating and glass fiber, low glass transition temperature of polymer, and aging of glass fiber. Achieve the effect of improving mechanical properties and anti-aging properties, reducing the possibility of spalling, and improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A preparation method for glass fiber mesh cloth latex, comprising the following steps,

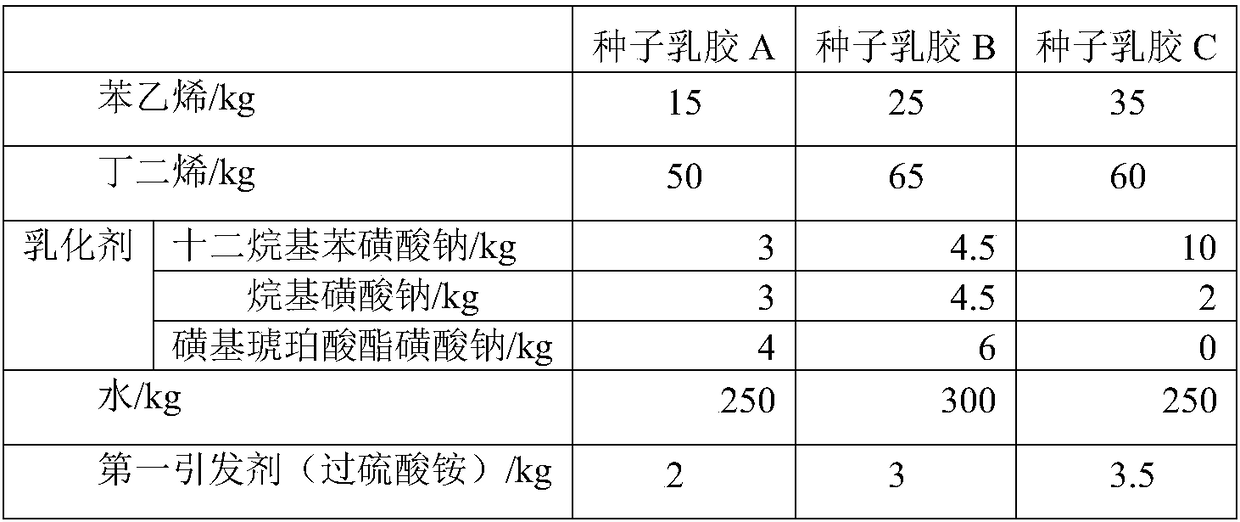

[0066] S1: Put 15-35kg of styrene, 50-65kg of butadiene, 10-15kg of emulsifier and 250-300kg of water at a time after the polymerization tank is evacuated, stir and heat up to 40-60°C, then add the first initiator 2- 3.5kg, keep the temperature and continue to stir the reaction for 10-25 hours, react until the conversion rate reaches above 98%, then cool down to below 30°C to obtain seed latex;

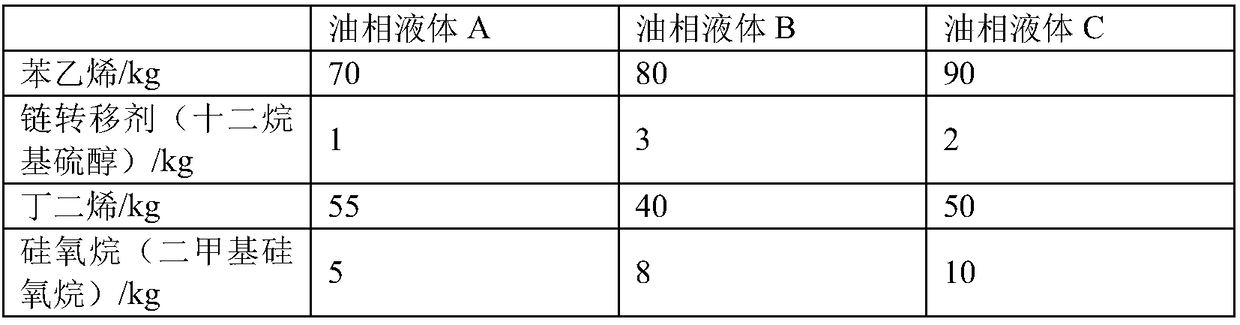

[0067] S2: Mix 70-90 kg of styrene and 1-3 kg of chain transfer agent evenly, then add 40-55 kg of butadiene and mix evenly, then add 5-10 kg of siloxane and mix evenly to obtain an oil phase liquid;

[0068] S3: Mix 3-8kg of crosslinking agent, 250-320kg of water and other raw materials of water phase liquid to obtain water phase liquid;

[0069] S4: uniformly mixing 7-12kg of the second initiator and 90-130kg of water to obtain an initiator solution;

[0070] S5: Add 15-20kg of seed lat...

Embodiment 2

[0095] A method for preparing glass fiber mesh cloth latex, which is improved on the basis of Example 1, the siloxane is vinyltrimethoxysilane, the corresponding latex is obtained, and the adhesion and peeling test is carried out. The test results are as follows.

[0096]

Embodiment 3

[0098] A preparation method of glass fiber mesh cloth latex, improved on the basis of Example 1, the siloxane is 3-butenetriethoxysilane, the corresponding latex is obtained, and the adhesion and peeling test is carried out, the test results are as follows .

[0099]

[0100]

[0101] It can be known from Example 2 and Example 3 that when siloxane is alkenyl siloxane, siloxane can be polymerized with butadiene monomer and styrene monomer, and the siloxane can be grafted into butadiene-benzene In the ethylene polymerization system, the compatibility of siloxane in the butadiene-styrene polymerization system can be strengthened; crosslinking can occur between siloxanes inserted into the butadiene-styrene polymerization system, and the butadiene can be improved. - The degree of cross-linking in the styrene polymerization system improves the bonding strength of the coating, and the siloxane is grafted into the butadiene-styrene polymerization system and then combined with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com