Porous scaffold provided with surface oriented functionally modified coating and preparation method of porous scaffold

A technology for porous stents and modified coatings, used in coatings, medical science, prostheses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

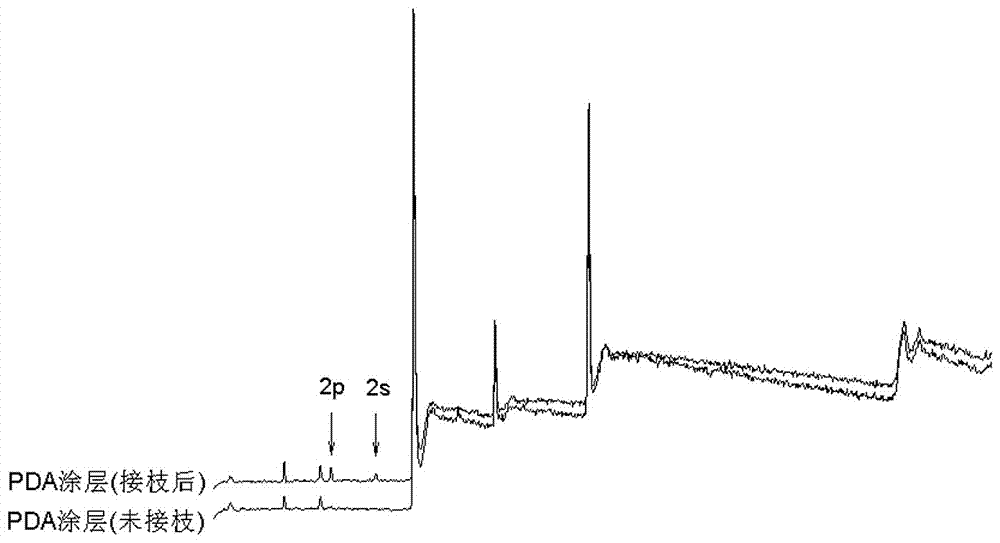

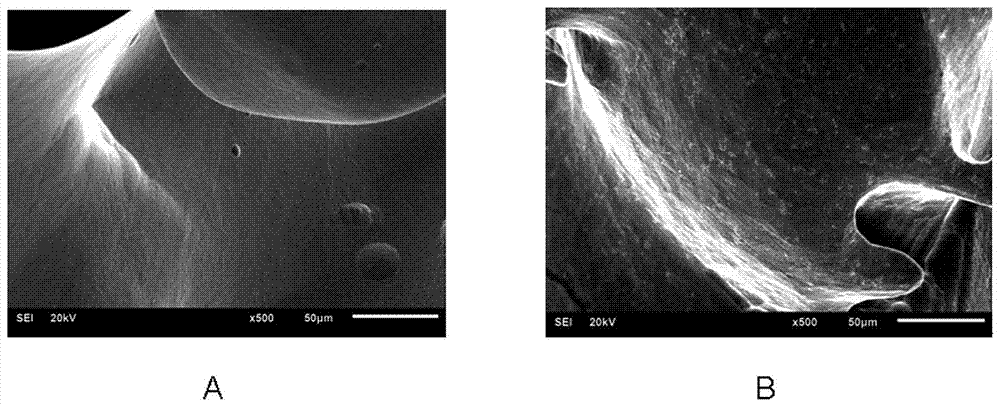

[0043] Example 1: Porous titanium alloy scaffold material with surface grafted chondroitin sulfate coating

[0044] The first step, the preparation of porous titanium alloy

[0045] The porous titanium alloy is prepared by 3D printing, with a length and width of 10mm and a height of 5mm. Ultrasonic cleaning with absolute ethanol for 10 minutes, then ultrasonic cleaning with distilled water for 5 minutes, and drying.

[0046] The second step, polydopamine coating preparation

[0047] The porous titanium alloy was soaked in a dopamine hydrochloride solution with a concentration of 2mg / ml, the concentration of Tris in the solution was 10mM, the pH value was 8.5, the soaking time was 48 hours, and the reaction temperature was 37°C. After the coating was deposited, it was ultrasonically cleaned with distilled water and absolute ethanol for 5 minutes, respectively, and dried. A substrate material with a structure of scaffold-polydopamine was formed. Repeat twice to form a double...

Embodiment 2

[0054] Example 2: Porous titanium alloy scaffold material with surface grafted chondroitin sulfate coating

[0055] The first step, the preparation of porous titanium alloy

[0056] The porous titanium alloy is prepared by 3D printing, with a length and width of 10mm and a height of 5mm. Ultrasonic cleaning with absolute ethanol for 10 minutes, then ultrasonic cleaning with distilled water for 5 minutes, and drying.

[0057] The second step, polydopamine coating preparation

[0058] The porous titanium alloy was soaked in a dopamine hydrochloride solution with a concentration of 2mg / ml, the concentration of Tris in the solution was 10mM, the pH value was 8.5, the soaking time was 48 hours, and the reaction temperature was 37°C. After the coating was deposited, it was ultrasonically cleaned with distilled water and absolute ethanol for 5 minutes, respectively, and dried. A substrate material with a structure of scaffold-polydopamine was formed. Repeat three times to form th...

Embodiment 3

[0067] Example 3: Porous titanium alloy stent material coated with terminal alkyne antibacterial drug terbinacol on the surface

[0068] The first step, the preparation of porous titanium alloy

[0069] The porous titanium alloy is prepared by 3D printing, with a length and width of 10mm and a height of 5mm. Ultrasonic cleaning with absolute ethanol for 10 minutes, then ultrasonic cleaning with distilled water for 5 minutes, and drying.

[0070] The second step, polydopamine coating preparation

[0071] The porous titanium alloy was soaked in a dopamine hydrochloride solution with a concentration of 2mg / ml, the concentration of Tris in the solution was 10mM, the pH value was 8.5, the soaking time was 48 hours, and the reaction temperature was 37°C. After the coating was deposited, it was ultrasonically cleaned with distilled water and absolute ethanol for 5 minutes, respectively, and dried. Repeat three times to form a three-layer polydopamine-coated base material.

[0072...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com