Toughened nylon blend and preparation method thereof

A blend, nylon technology, applied in the field of polymer blending and processing modification, to reduce residual monomers and increase grafting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

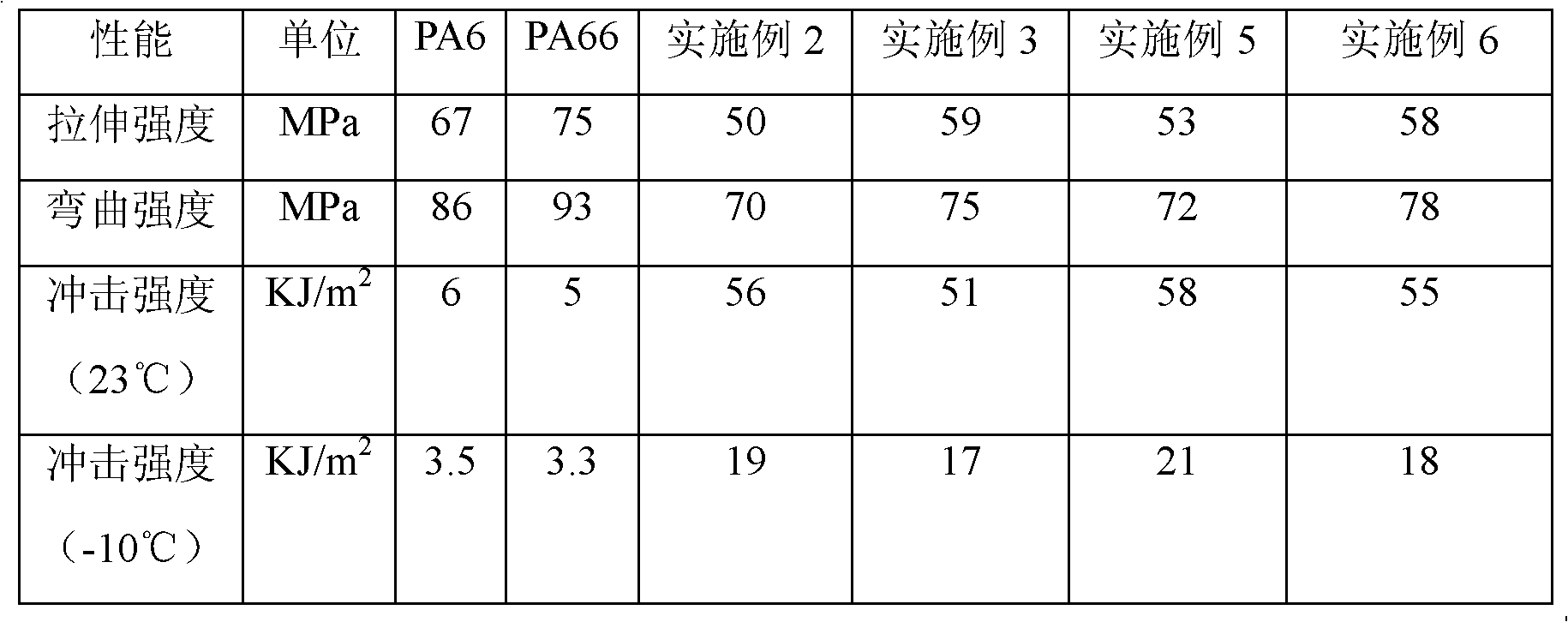

Examples

preparation example Construction

[0023] The preparation method of the toughening agent can be expressed as: after mixing POE, PP, EAA and 50% maleic anhydride and the peroxide initiator uniformly, the material is fed from the main feeding port of the twin-screw extruder Join in the extruder, the maleic anhydride of remaining 50% and peroxide initiator are injected in the extruder in the extruder 3rd zone by metering pump, through extruding granulation and drying, obtain the present invention. toughening agent. Wherein, the temperature of the extruder is set at 100-200°C.

[0024] Preferably, the antioxidant is tetrakis[β-(3,5-di-tert-butyl 4-hydroxyphenyl)propionic acid]pentaerythritol ester and tris(2,4-di-tert-butylphenyl)phosphite A mixture with a mass ratio of 1:1.

Embodiment 1

[0025] Embodiment 1 (toughening agent preparation embodiment)

[0026] The toughening agent component (100%) is calculated by weight percentage: POE 60%, PP 30%, EAA 8%, maleic anhydride 1.6%, dicumyl peroxide 0.4%. Blend the above POE, PP, EAA, 50% maleic anhydride and 50% dicumyl peroxide evenly and then add them to the twin-screw extruder, and dissolve the remaining maleic anhydride and dicumyl peroxide in acetone Finally, it is injected into the third zone of the extruder through a metering pump, and the toughening agent is obtained after extrusion, granulation and drying. The temperature settings of the extruder from the first zone to the tenth zone are: 100°C, 170°C, 180°C, 190°C, 200°C, 200°C, 200°C, 200°C, 200°C, 190°C. The rotational speed of the extruder was 300 RPM, and the length-to-diameter ratio of the extruder was 42.

Embodiment 2

[0027] Embodiment 2 (preparation embodiment of toughened nylon blend)

[0028] The toughened nylon blend is calculated by weight percentage: nylon 6 84.7%, the toughening agent 15% of embodiment 1, antioxidant tetrakis [β-(3,5-di-tert-butyl 4-hydroxyphenyl) propionic acid ] Pentaerythritol ester 0.15%, antioxidant tris (2,4-di-tert-butylphenyl) phosphite 0.15%. The above-mentioned components were added into a high-speed mixer and mixed for 3 minutes, then added into a twin-screw extruder, extruded, granulated and dried to obtain the toughened nylon blend of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com