Preparation method of graphene oxide modified waterborne polyurethane anti-corrosive emulsion

A water-based polyurethane and graphene modification technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve problems such as uniform dispersion, coating defects, and graphene is difficult to play a physical partition effect, and achieves improved dispersion. Stability, the effect of improving shielding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

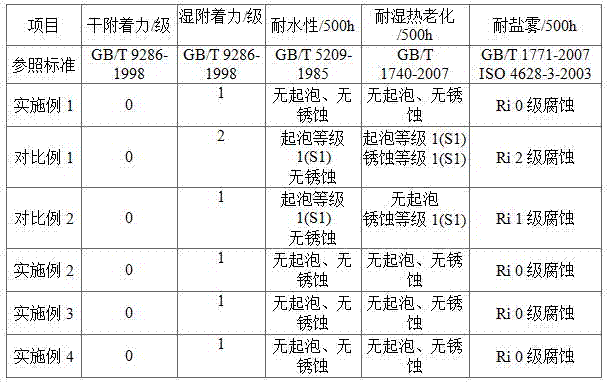

Examples

Embodiment 1

[0022] Add 100 parts by mass of N,N-dimethylformamide, 20 parts by mass of graphene oxide, 1 part by mass of triethylamine, and 2 parts by mass of glycidyl neodecanoate in the reactor, and react at 130°C for 4 hours. The reaction material is cooled to 30°C, centrifuged, and the centrifugal filter cake is placed in a vacuum dryer at 80°C, controlled with an absolute pressure of ≤20Pa, and dried for 4 hours to obtain modified graphene oxide;

[0023] Add 0.2 parts by mass of the modified graphene oxide obtained in step 1, 25 parts by mass of isophorone diisocyanate, and 25 parts by mass of poly-1,4-butylene adipate, and react at 85°C for 3 hours , cooled to 60°C, and then added 2 parts by mass of dibutyltin dilaurate, 6 parts by mass of N-methylpyrrolidone, 10 parts by mass of E-44 epoxy resin, 8 parts by mass of 2,2-dimethylolpropionic acid , 2 parts by mass of trimethylolpropane were reacted for 5 hours, 4 parts by mass of triethylamine was added at 60°C for 1 hour, 70 parts b...

Embodiment 2

[0029] Add 100 parts by mass of N,N-dimethylformamide, 40 parts by mass of graphene oxide, 2 parts by mass of N-methylimidazole, and 4 parts by mass of glycidyl neodecanoate in the reactor, and react at 120°C for 5 hours , cooling the reaction material to 30°C, centrifuging, placing the centrifugal filter cake in a vacuum dryer at 80°C, controlling the absolute pressure ≤ 20Pa, and drying for 4 hours to obtain modified graphene oxide.

[0030] Add 0.1 parts by mass of the modified graphene oxide obtained in step 1, 20 parts by mass of isophorone diisocyanate, and 20 parts by mass of poly-1,4-butylene adipate, and react at 85°C for 3 hours , cooled to 60°C, and then added 4 parts by mass of dibutyltin dilaurate, 8 parts by mass of N-methylpyrrolidone, 5 parts by mass of E-20 type epoxy resin, 10 parts by mass of 2,2-dimethylolpropionic acid , 1 mass part of trimethylolpropane was reacted for 5 hours, 3 mass parts of triethylamine was added at 60°C for 1 hour, 90 mass parts of d...

Embodiment 3

[0032] Add 100 parts by mass of N,N-dimethylformamide, 60 parts by mass of graphene oxide, 3 parts by mass of triphenylphosphine, and 3 parts by mass of glycidyl neodecanoate into the reactor, and react at 150°C for 3 hours. The reaction material was cooled to 30°C, centrifuged, and the centrifugal filter cake was placed in a vacuum dryer at 80°C, controlled with an absolute pressure of ≤20Pa, and dried for 4 hours to obtain modified graphene oxide.

[0033] Add 0.5 parts by mass of the modified graphene oxide obtained in step 1, 40 parts by mass of isophorone diisocyanate, and 40 parts by mass of poly-1,4-butylene adipate, and react at 85°C for 3 hours , cooled to 60°C, and then added 5 parts by mass of dibutyltin dilaurate, 5 parts by mass of N-methylpyrrolidone, 15 parts by mass of E-51 epoxy resin, 5 parts by mass of 2,2-dimethylol propionic acid , 3 parts by mass of trimethylolpropane were reacted for 5 hours, 4 parts by mass of triethylamine was added at 60°C for 1 hour,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com