Waterborne single-component transparent anti-corrosion coating based on dual-functionalized nano-SiO2 and preparation method of coating

An anti-corrosion coating, dual-function technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as water resistance decline, and achieve the effect of improving adhesion and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

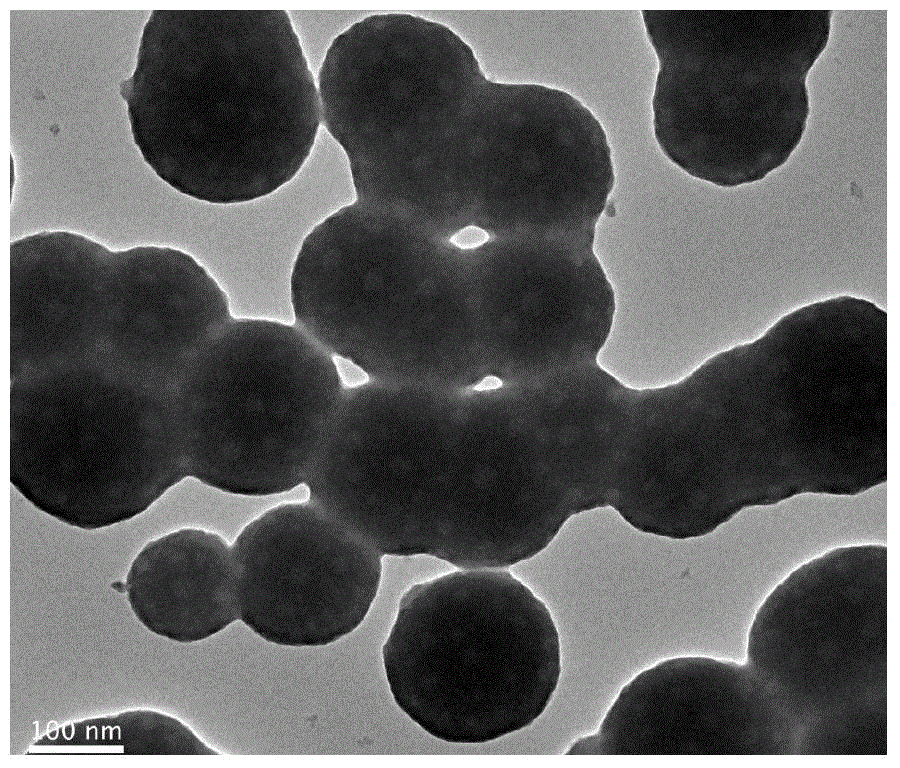

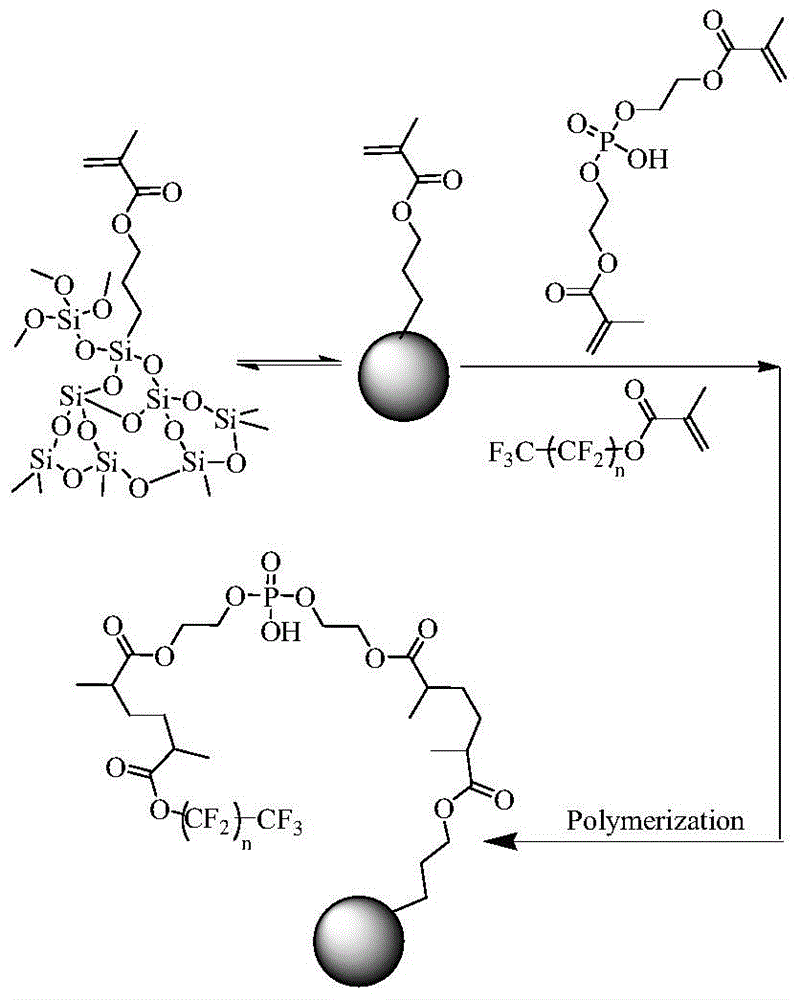

[0032] Bifunctional nano-SiO 2 Preparation of:

[0033] Add 1kg tetraethyl orthosilicate, 5kg ethanol, and ammonia water to adjust the pH value to 8, and react at 20°C for 10 hours to obtain monodisperse nano-SiO with translucent blue fluorescence. 2 sol; then add 0.1kg vinyltrimethoxysilane and react at 20°C for 5h to prepare nano-SiO with double bond modification on the surface 2 Sol; heat up to 50°C, add 1g of tert-butyl hydroperoxide to the above-mentioned double bond modified silica sol, slowly add 0.11kg of hydrogen phosphate di(methacryloyloxyethyl) ester, 0.09kg of hexamethacrylate A mixed solution of fluorobutyl ester and 1g N,N-dimethylaniline, reacted at 50°C for 3 hours after dropping, distilled off ethanol, and pulverized to obtain fluorine-containing phosphorus-containing bifunctional nano-SiO 2 particles.

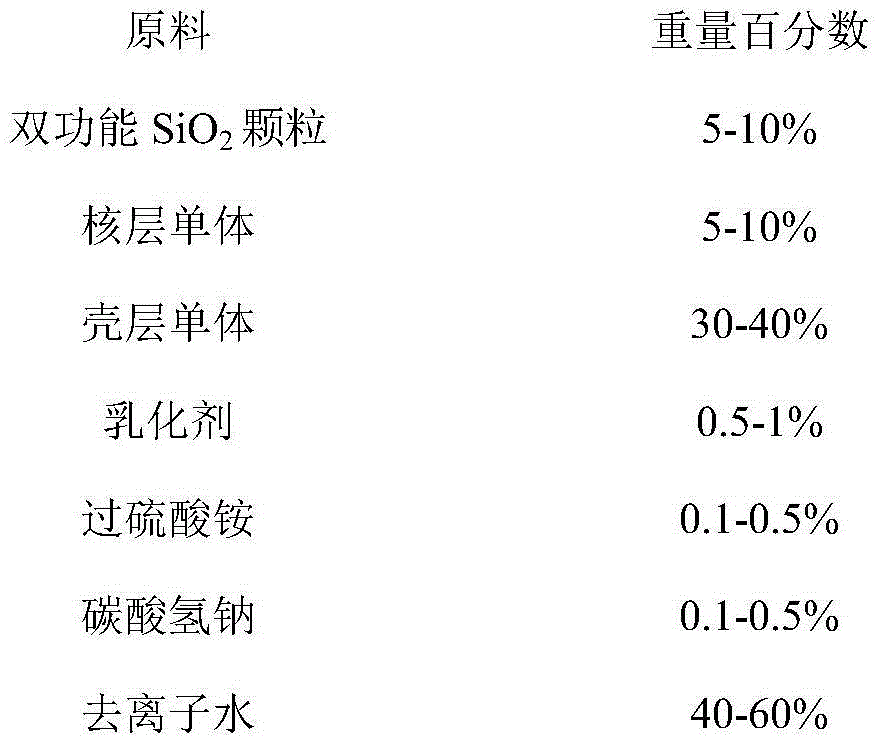

[0034] Preparation of organic-inorganic hybrid emulsion:

[0035] (1) Core layer pre-emulsion: Add 2.5g sodium lauryl sulfate, 2.5g OP-10, 0.3kg deionize...

Embodiment 2

[0039] Bifunctional nano-SiO 2 Preparation of:

[0040] Add 1kg tetraethyl orthosilicate, 10kg ethanol, and ammonia water to adjust the pH value to 8, and react at 25°C for 8 hours to prepare monodisperse nano-SiO with translucent blue fluorescence. 2 sol; add 0.1kg vinyltriethoxysilane and 0.1kg γ-methacryloxypropyltrimethoxysilane to react at 25°C for 4h to prepare nano-SiO with double bond modification on the surface 2 Sol; heat up to 55°C, add 10g of tert-butyl hydroperoxide to the above-mentioned double bond modified silica sol, slowly add 0.6kg of hydrogen phosphate di(methacryloyloxyethyl) ester, 0.2kg of trimethacrylate A mixed solution of fluoroethyl ester, 0.2kg hexafluorobutyl methacrylate and 10g N,N-dimethylaniline, react at 55°C for 5h after dropping, distill off ethanol, and pulverize to obtain fluorine-containing phosphorus-containing bifunctional nano-SiO 2 particles.

[0041] Preparation of organic-inorganic hybrid emulsion:

[0042] (1) Core layer pre-em...

Embodiment 3

[0046] Bifunctional nano-SiO 2 Preparation of:

[0047] Add 1kg tetraethyl orthosilicate, 8kg ethanol, and ammonia water to adjust the pH to 8, and react at 30°C for 5 hours to prepare monodisperse nano-SiO with translucent blue fluorescence. 2 sol; then add 0.15kg γ-methacryloxypropyltrimethoxysilane to react at 30°C for 5h to prepare nano-SiO with double bond modification on the surface 2 Sol; heat up to 60°C, add 3.6g tert-butyl hydroperoxide to the above-mentioned double bond modified silica sol, slowly add 0.31kg hydrogen phosphate di(methacryloyloxyethyl) ester, 0.29kg methacrylic acid A mixed solution of dodecafluoroheptyl ester and 3.6g N,N-dimethylaniline, reacted at 60°C for 2 hours after dropping, distilled ethanol, and pulverized to obtain fluorine-containing phosphorus-containing bifunctional nano-SiO 2 particles.

[0048] Preparation of organic-inorganic hybrid emulsion:

[0049] (1) Core layer pre-emulsion: add 4.3g allyloxy nonylphenol propanol polyoxyethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com