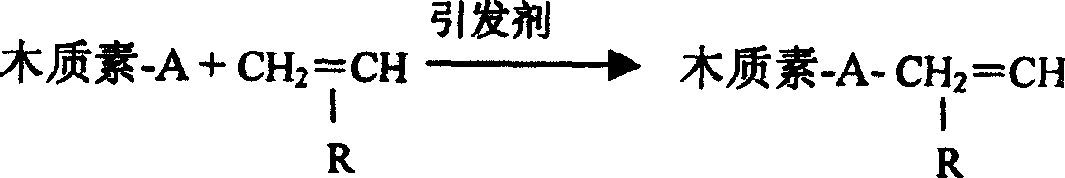

Process for preparing modified lignocellulose sulfonate graft copolymer

A technology of lignosulfonate and graft copolymers, which is applied in the field of preparation of modified lignosulfonate graft copolymers, can solve the problems of slow reaction speed and low grafting efficiency, and achieve the improvement of grafting efficiency , improve utilization and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Modification of lignosulfonate by maleic anhydride

[0017] 100 g of purified lignosulfonate and 50 g of maleic anhydride were placed in a stainless steel sealed tank, mixed evenly, and then placed in an oil bath to heat up, react at a certain temperature for a certain period of time, take out the product after cooling, and soak it in acetone for 24 hours. , washed twice with acetone to remove unreacted maleic anhydride, and dried at 60°C in an oven to obtain maleic anhydride-modified lignin.

Embodiment 2

[0018] Example 2: Modification of lignosulfonate by acryloyl chloride

[0019] Dissolve 100 g of the purified lignosulfonate in 200 ml of dimethyl sulfoxide, add 30 ml of acryloyl chloride dropwise at room temperature, and after the reaction is completed, add triethylamine dropwise to neutralize the hydrochloric acid in the product, and then add ether The modified lignosulfonate was precipitated, centrifuged, and washed three times with absolute ethanol to remove triethylamine hydrochloride to obtain acryloyl chloride-modified lignin.

Embodiment 3

[0020] Example 3: Grafting reaction of maleic anhydride modified lignosulfonate with MMA and BA (molar ratio of lignosulfonate to monomer is 1:5) Components:

[0021] A. Water 40g

[0022] OP-10 0.65g

[0023] OS(40%) 0.6g

[0024] B. Acrylic acid (AA) 2g

[0025] Ammonia (26%) 0.2g

[0026] C. Methyl methacrylate (MMA) 40g

[0027] Butyl acrylate (BA) 48.5g

[0028] Tert-butyl hydroperoxide (THP) 0.5g

[0029] D. Maleic anhydride modified lignosulfonate 30% solution 60g

[0030] NaHSO 3 0.5g

[0031] E. Appropriate amount of water

[0032] Na 2 HPO 4 0.5g

[0033] Put component A into a 500ml three-necked bottle equipped with a stirring device and a dropping funnel, gradually add components B and C under stirring, and continue stirring for a period of time after adding to obtain a stable monomer emulsion. 10% of which is added to component E as a monomer emulsion for seeds.

[0034] Add the seed polymerizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com