Modification compatibilizer of PPO/PA (Poly-p-phenylene oxide/polyacrylate) alloy and PPO/PA alloy

A compatibilizer and alloy technology, applied in the field of PPO/PA alloy modification compatibilizer and PPO/PA alloy, can solve the problems of lack of reactive graft points, poor melt fluidity and high temperature in molecular chains, and achieve industrial application Good condition, improved compatibility, improved mechanical properties and effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

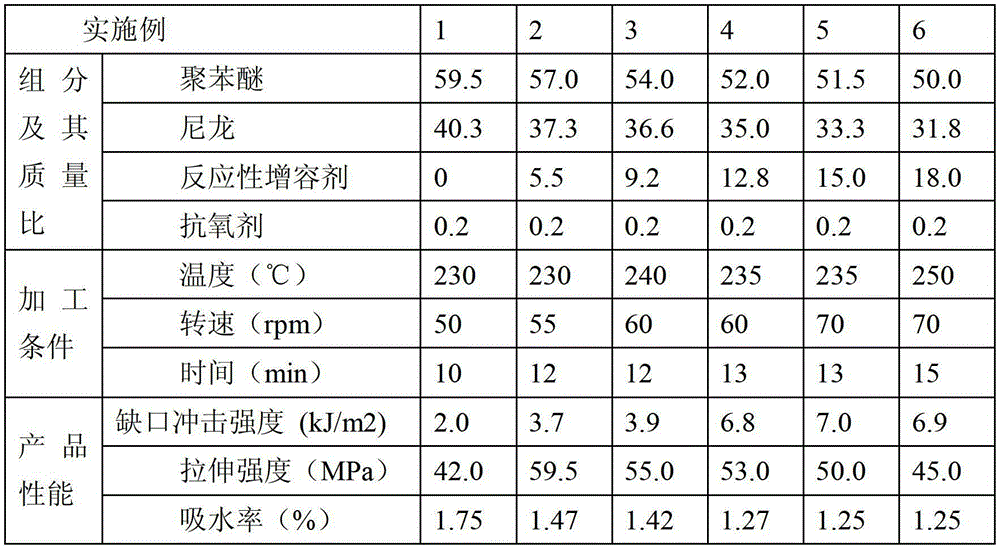

Examples

Embodiment Construction

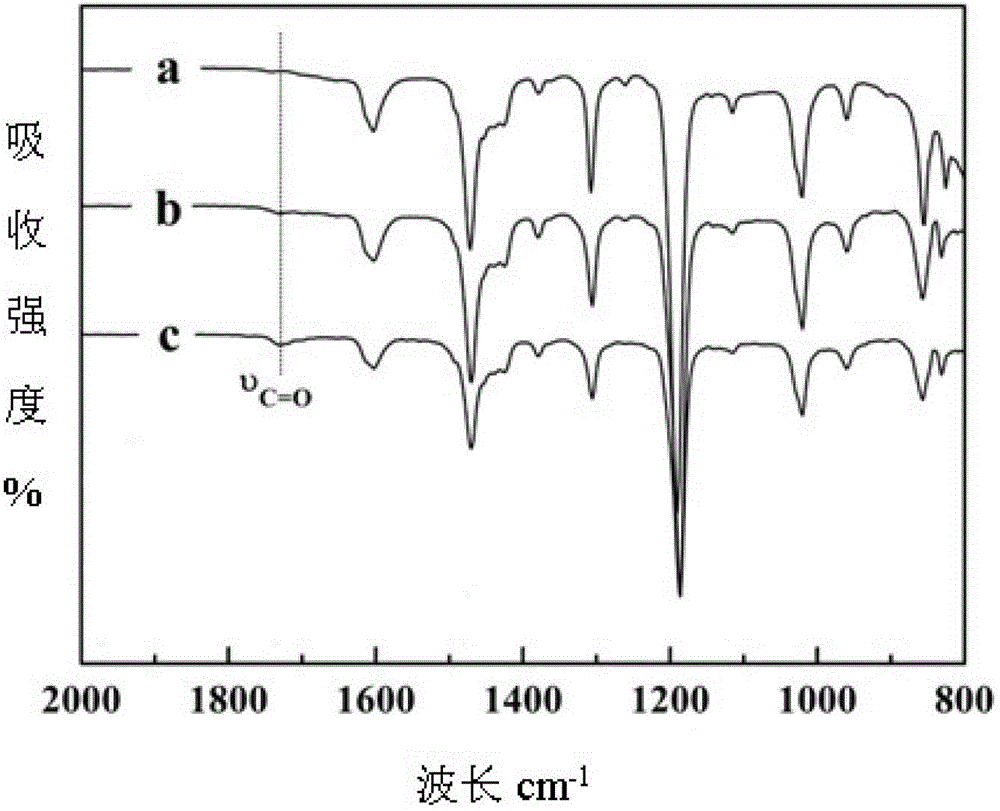

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] 1. Preparation of PPO / PA alloy modified compatibilizer

[0028] (1) Glycidyl methacrylate (GMA) and styrene (St) are configured into a mixed solution according to a mass ratio of 1:1, and then the initiator dicumyl peroxide, which accounts for 5% of the total graft monomer (DCP) was added to the grafted monomer mixture to dissolve;

[0029] (2) Mix the polyphenylene ether PPO and graft monomer mixture in a mixer for 5-10 minutes, and the graft monomer mixture accounts for 8% of the total mixture weight;

[0030] (3) Put the mixed total mixture into the torque rheometer for melting and grafting reaction, the reaction temperature is 220-250°C, the rotation speed is 50-70rpm, and the reaction time is 6-10min.

[0031] (4) After the reaction, the material was cooled, and then pulverized by a pulverizer to obtain particles of functionalize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com