Method for forming multilayered coating film

A multi-layer coating, coating technology, applied in the direction of coatings, polyurea/polyurethane coatings, devices for coating liquids on surfaces, etc. Coating film and other problems in hardness and chipping resistance, to achieve the effect of excellent hardness and excellent chipping resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0156] The following examples are given to describe the present invention more specifically. It should be noted that the scope of the present invention is not limited to these examples. In addition, "part" and "%" in an Example represent "part by mass" and "% by mass", respectively.

[0157] Water-based 1st base coat paint (A):

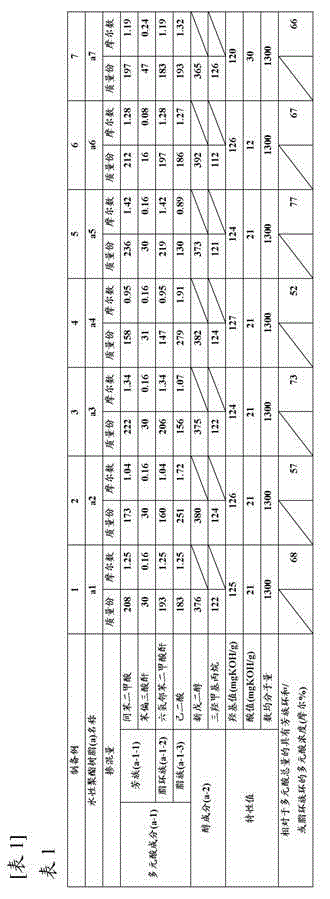

[0158] Preparation of waterborne polyester resin (a)

preparation example 1

[0160] 193 parts of hexahydrophthalic anhydride, 208 parts of isophthalic acid, 183 parts of adipic acid, 376 parts of neopentyl glycol and 122 parts of trimethylolpropane, and the temperature was raised between 160°C and 230°C for 3 hours. Thereafter, condensation reaction was performed until the acid value became 3 mgKOH / g or less while maintaining the temperature at 230° C. while distilling off generated moisture with a water separator. Next, in order to add a carboxyl group to the obtained condensation reaction product, further add 30 parts of trimellitic anhydride, react at 170° C. for 30 minutes, cool to below 60° C., and add 0.9 equivalent of 2-( Dimethylamino)ethanol was slowly added to deionized water after neutralization, thereby obtaining a product having a hydroxyl value of 125 mgKOH / g, an acid value of 21 mgKOH / g, a number average molecular weight of 1,300, a solid content of 45%, and a pH of 7.5. Waterborne polyester resin (a1).

preparation example 2~7

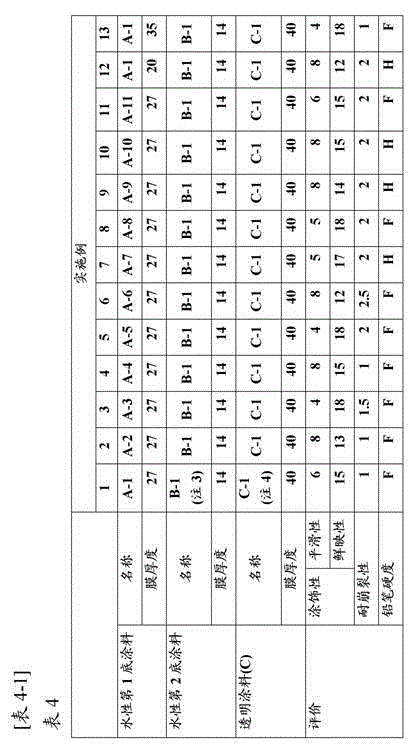

[0162] The blending composition of the polybasic acid component (a-1) and the alcohol component (a-2) is shown in Table 1 below, except that, the same operation as in Preparation Example 1 was obtained to obtain the hydroxyl value shown in Table 1, Aqueous polyester resins (a2) to (a7) having an acid value and a solid content of number average molecular weight of 45% and pH 7.5. In addition, the water-based polyester resin (a6) was not evaluated after that because it was difficult to prepare a stable aqueous dispersion.

[0163]

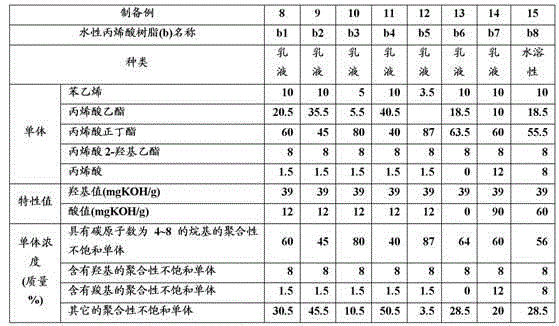

[0164] Preparation of water-based acrylic resin (b)

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com