Surface-coated cutting tool

A cutting tool and coating technology, which is applied in the direction of manufacturing tools, workpieces, drilling accessories, etc., to achieve the effects of excellent defect resistance, excellent peeling resistance, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

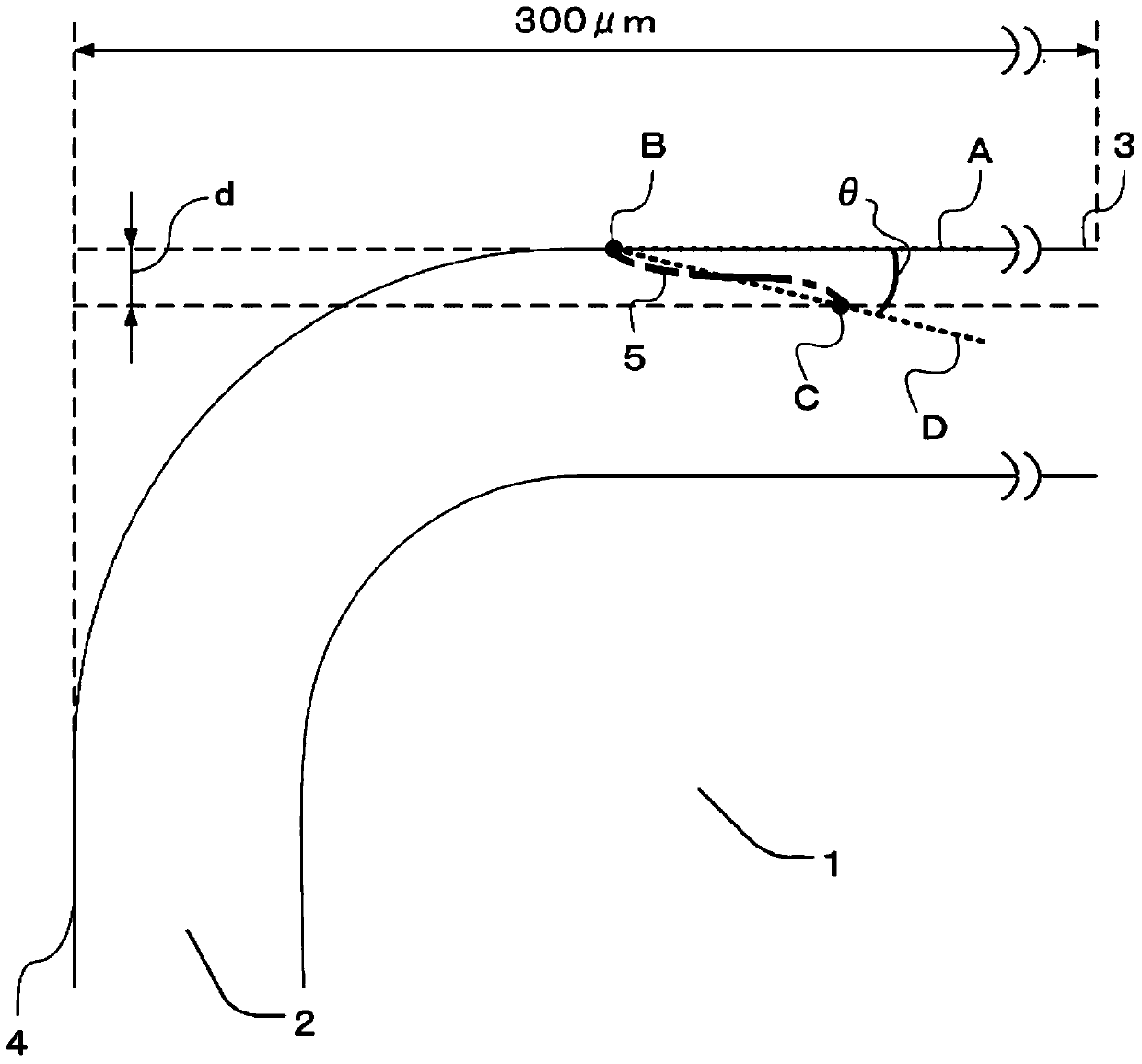

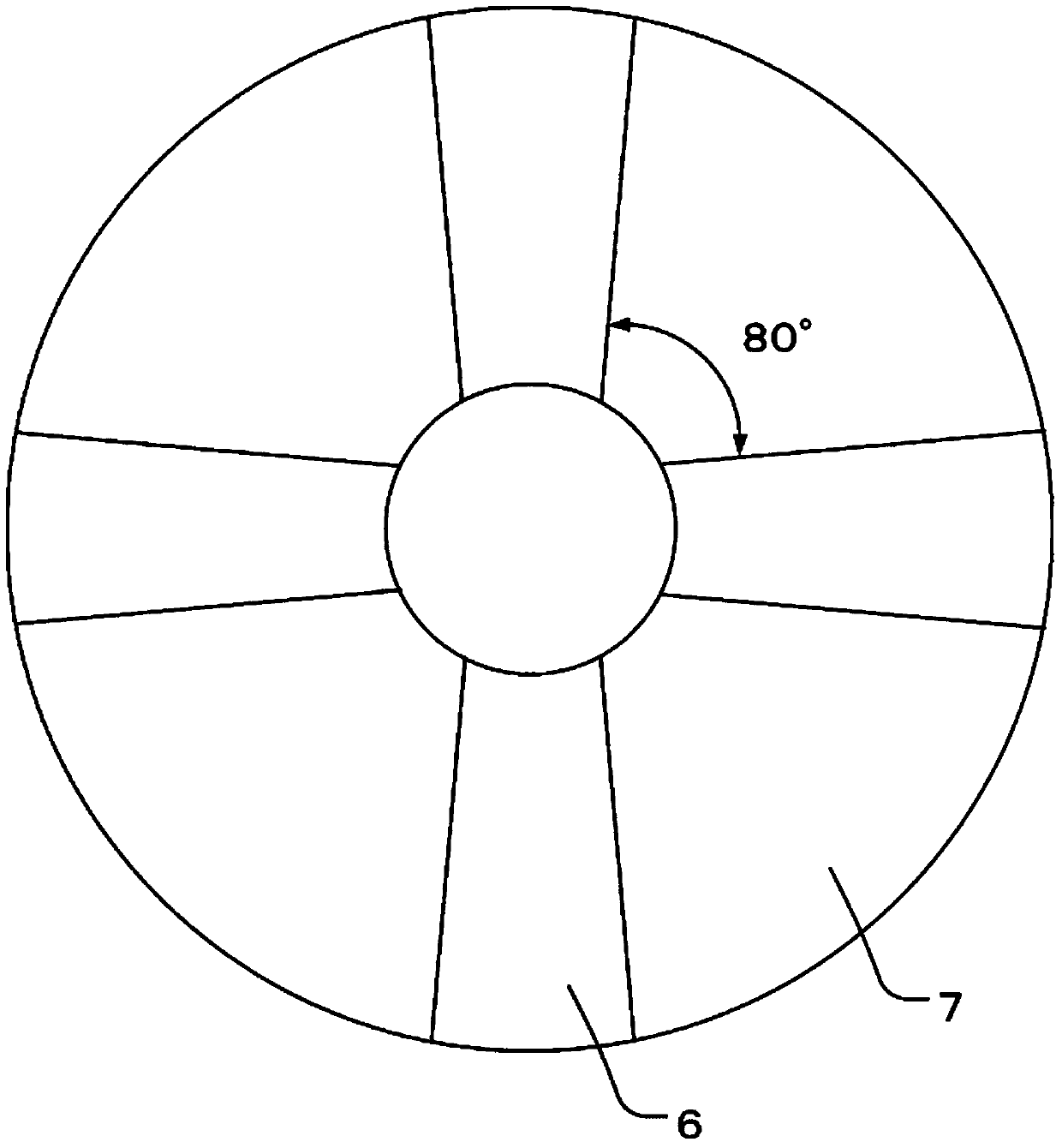

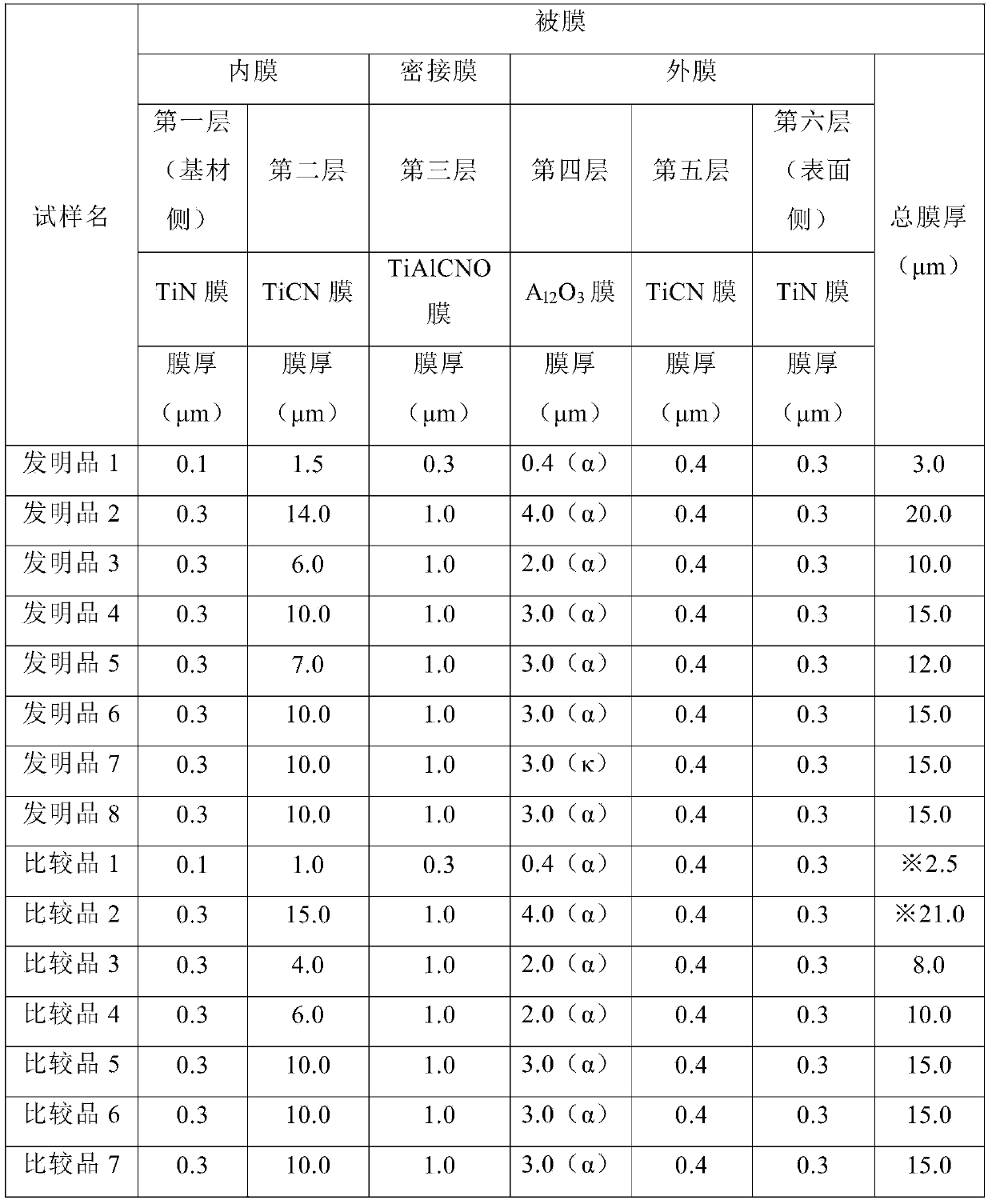

[0063] Sintered WC powder with an average particle size of 4.5 μm: 89% by weight, TiCN powder with an average particle size of 1.5 μm: 2% by weight, (Ta, Nb) C powder with an average particle size of 1.5 μm: 2% by weight, an average particle size of 1.5 μm Co powder: 7% by weight mixed powder to obtain a WC-(Ti, W, Ta, Nb) (C, N)-Co-based WC-based cemented carbide. This WC-based cemented carbide was processed into an insert in the shape of ISO standard CNMG120412, and this was used as a base material. In addition, a beta-depleted layer consisting only of WC and Co was formed near the surface of the WC-based cemented carbide substrate. The thickness of the de-beta layer in the flank was 15 μm. A film having the film composition shown in Table 1 was formed on the surface of the WC-based cemented carbide substrate by chemical vapor deposition. In addition, the 4th layer of Table 1 (Al 2 o 3 film) in (α) means α-type Al 2 o 3 Membrane, (κ) indicates κ-type Al 2 o 3 membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com