Surface-coated cutting tool with hard coating layer having excellent abrasion resistance

A cutting tool and surface coating technology, applied in the field of surface-coated cutting tools made of tungsten carbide-based cemented carbide, can solve the problems such as the easy occurrence of defects in the cutting edge, achieve increased resistance, prolonged life, and excellent cutting performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] WC powder, TiC powder, VC powder, TaC powder, NbC powder, Cr 3 C 2 Powder, and Co powder, these raw material powders are compounded into the compounding composition shown in Table 1, and wet mixed with a ball mill for 72 hours and dried, then extruded into a compact with a pressure of 100MPa, in a vacuum of 6Pa, at a temperature of: The green compact was sintered at 1400°C for 1 hour. After sintering, the blade was honed with R: 0.03 to form a WC-based cemented carbide tool base 1- 10.

[0064] [Table 1]

[0065]

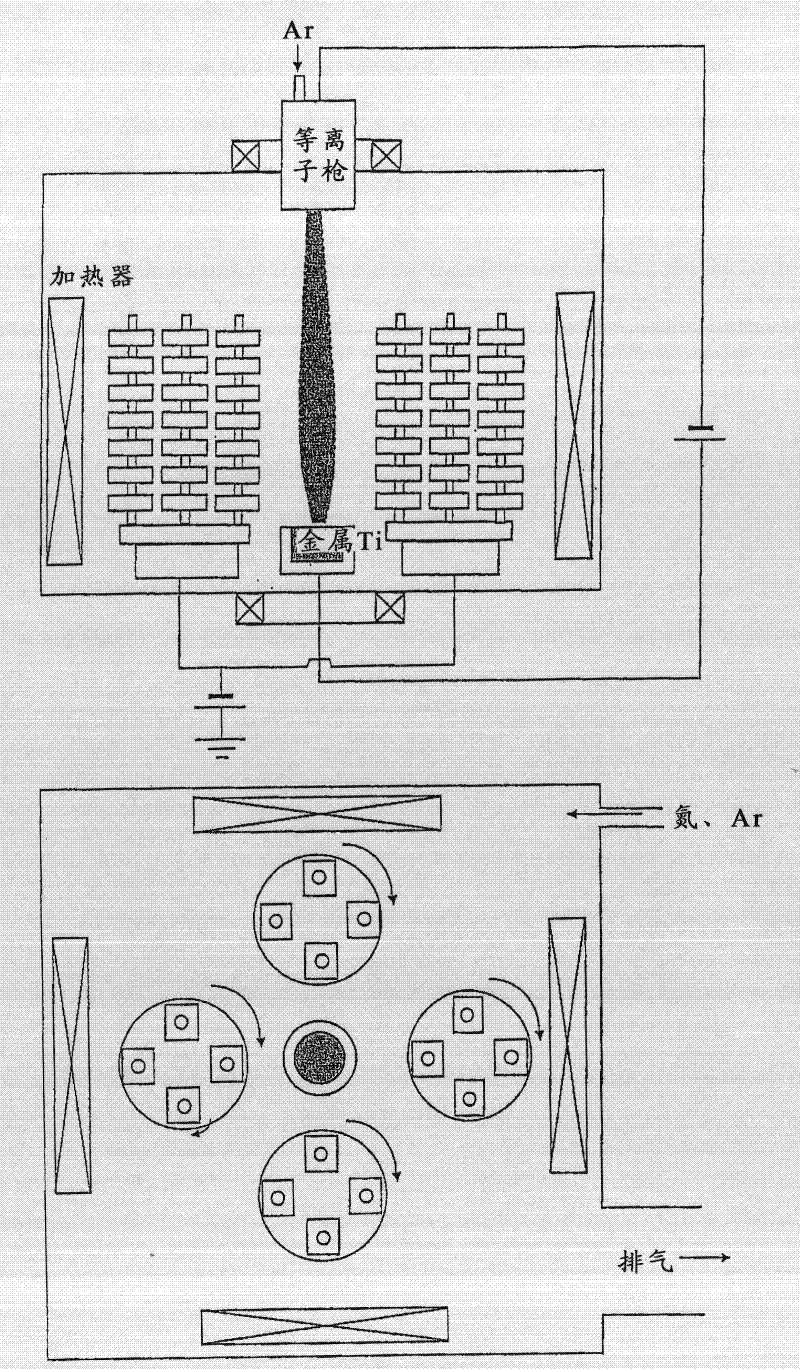

[0066] Next, in the state where the above-mentioned tool substrates 1 to 10 were ultrasonically cleaned in acetone and dried, they were mounted on figure 1 In the shown ion plating device using a pressure gradient Ar plasma gun, metal Ti is installed as an evaporation source, and first, the device is exhausted to maintain a temperature of 1.0×10 -3 In a vacuum below Pa, after heating the inside of the device to 240-400°C with a heater, introduce Ar gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com