Coated cutting tool

A cutting tool and coating technology, applied in the direction of manufacturing tools, workpieces, drilling tool accessories, etc., can solve problems such as inability to extend tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

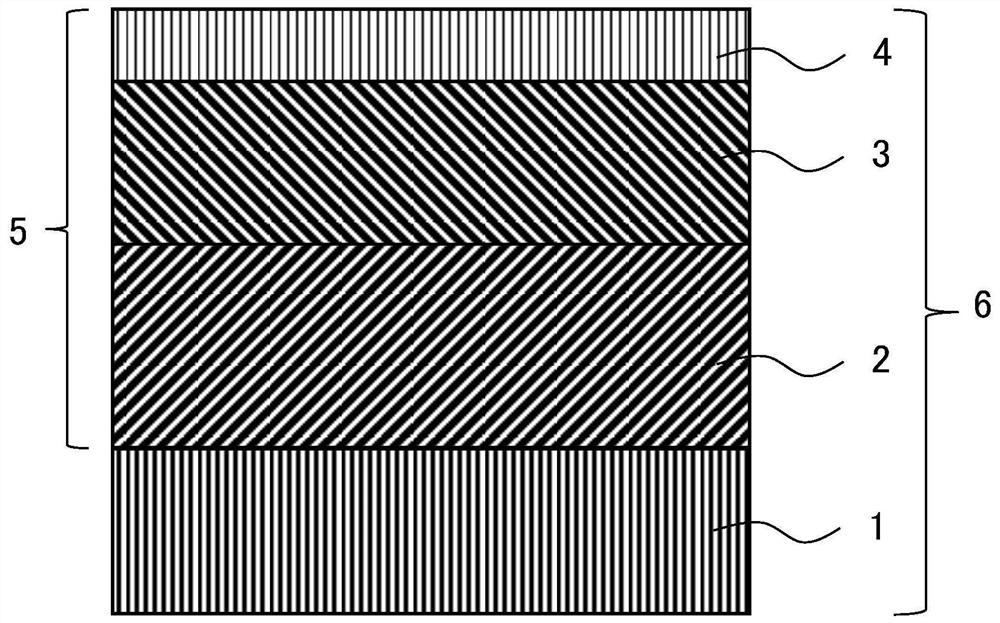

Image

Examples

Embodiment

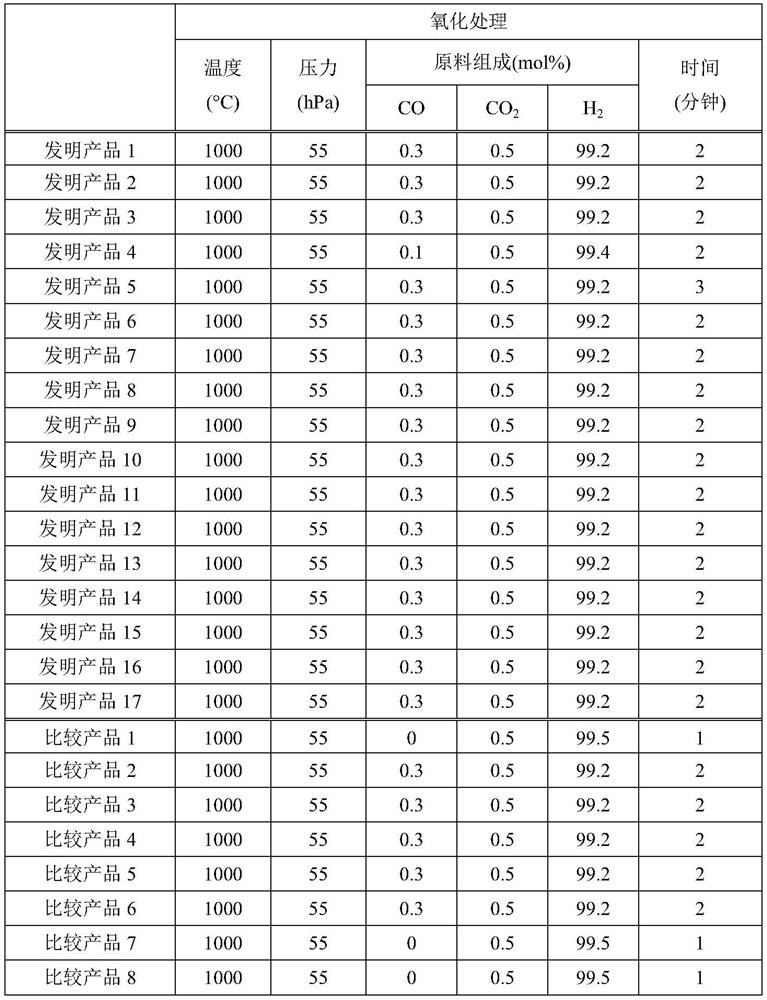

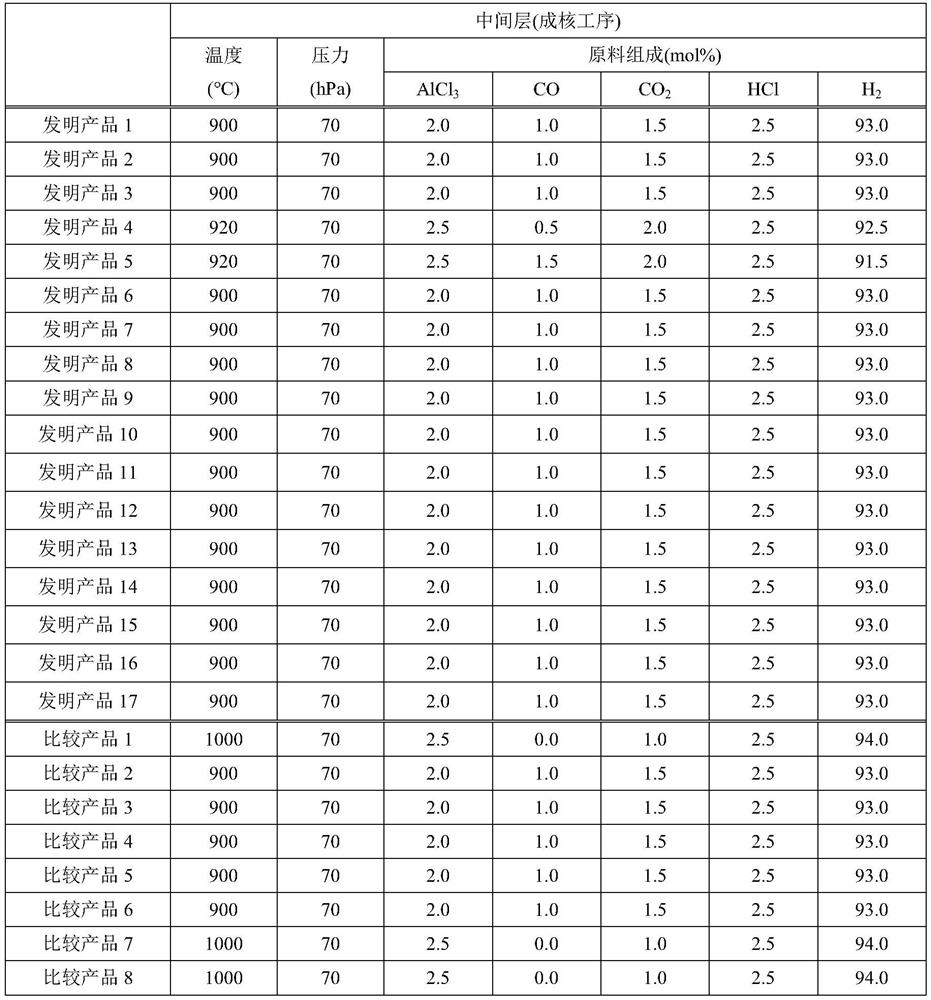

[0119] Hereinafter, although an Example is given and this invention is demonstrated in more detail, this invention is not limited to these Examples.

[0120] [Substrate]

[0121] The following substrates were used by cleaning the surface of the substrate after rounding the ridge line portion of the tip with a SiC brush.

[0122]

[0123] Shape: CNMG120412

[0124] Material: Carbide (88.9WC-7.9Co-1.5TiN-1.4NbC-0.3Cr 3 C 2 (The above is mass %))

[0125]

[0126] Shape: CNMG120412

[0127] Material: Carbide (89.7WC-7.1Co-1.5TiN-1.5NbC-0.2Cr 3 C 2 (The above is mass %))

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com