Coated cutting tool

A cutting tool and coating technology, which is applied in the direction of manufacturing tools, workpieces, turning equipment, etc., can solve the problems of inability to prolong tool life, and achieve the effects of prolonging tool life, excellent wear resistance and defect resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

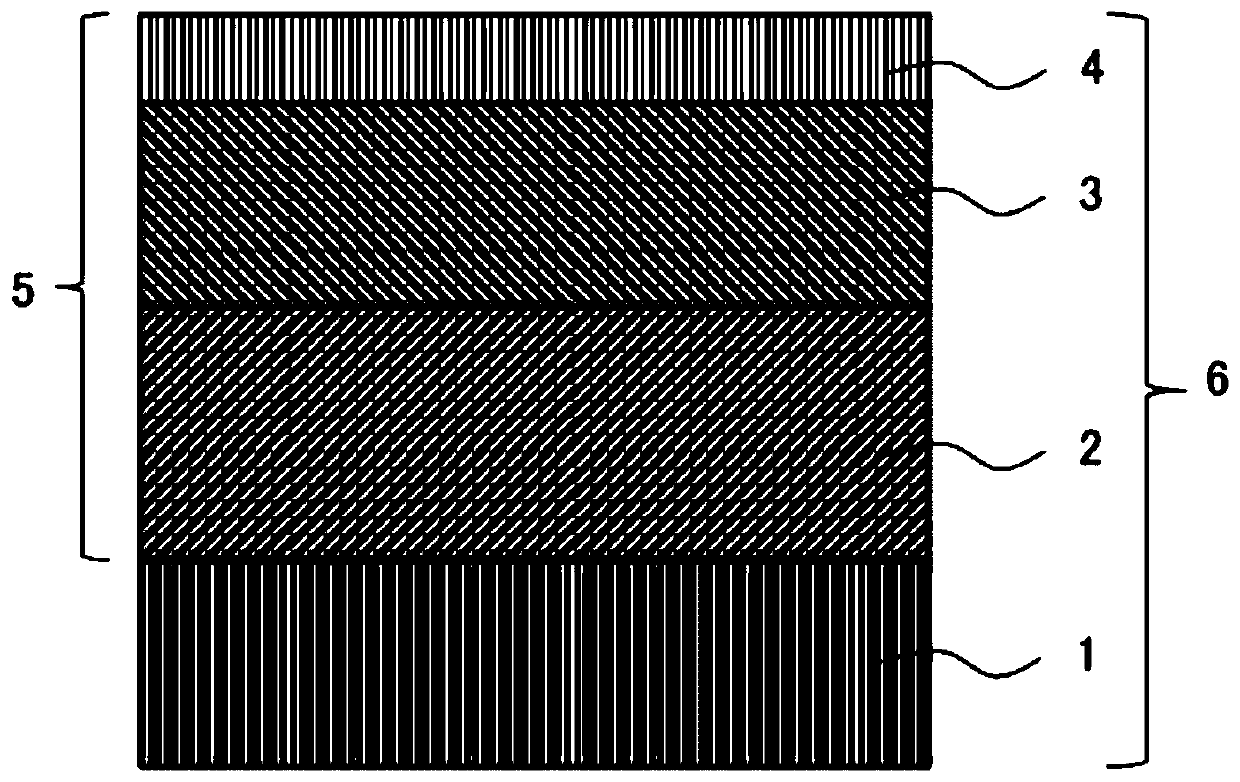

Image

Examples

Embodiment

[0088] Hereinafter, the present invention will be explained in more detail through examples, but the present invention is not limited to these examples.

[0089] As a base material, it is prepared to be processed into the blade shape of CNMG120412 and has 87.0WC-8.6Co-2.0TiN-2.0NbC-0.4Cr 3 C 2 (The above is a cemented carbide with a composition of mass %). After rounding the ridgeline portion of the tip of the base material with a SiC brush, the surface of the base material is cleaned.

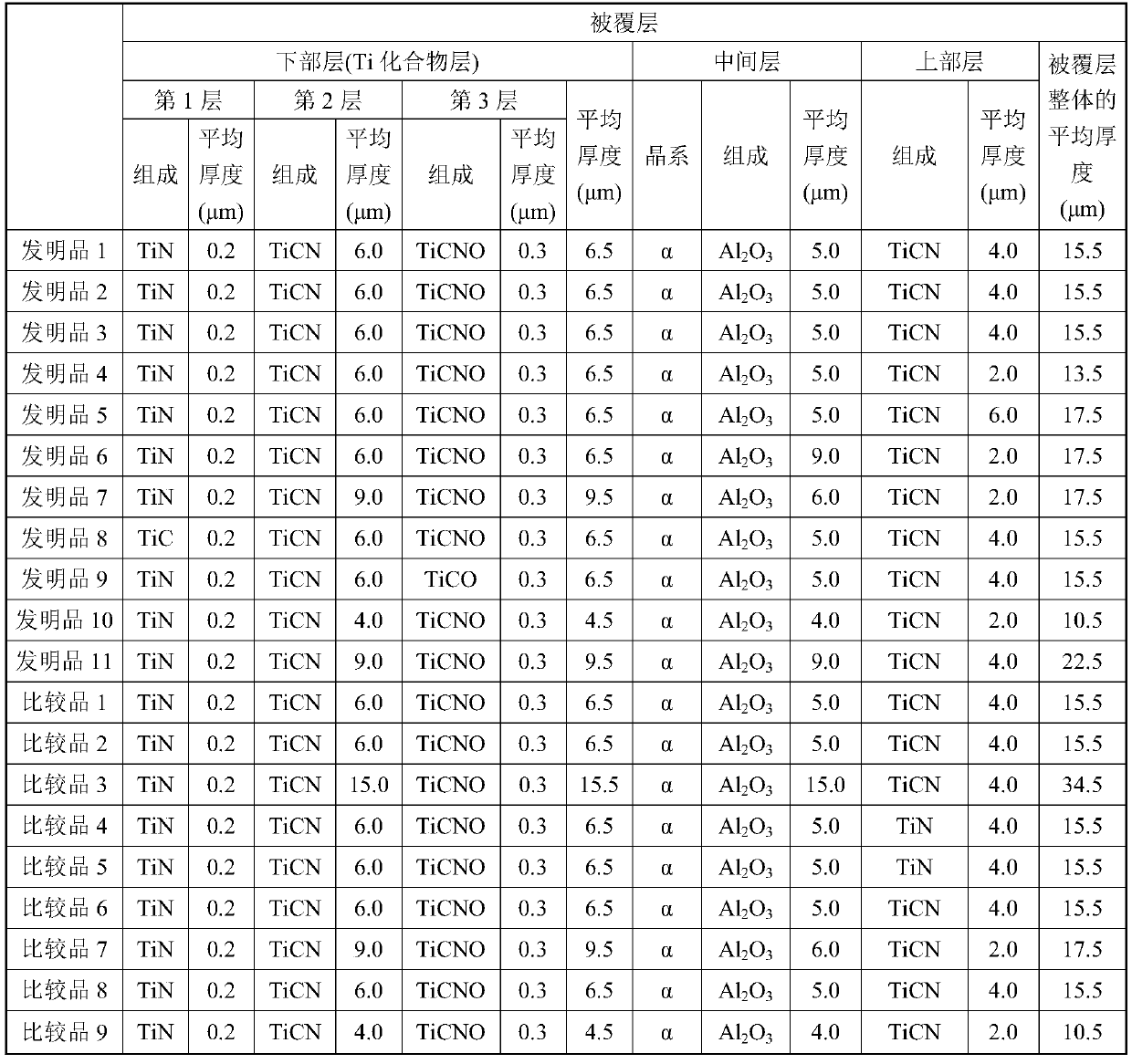

[0090] [Invention products 1-11 and comparative products 1-9]

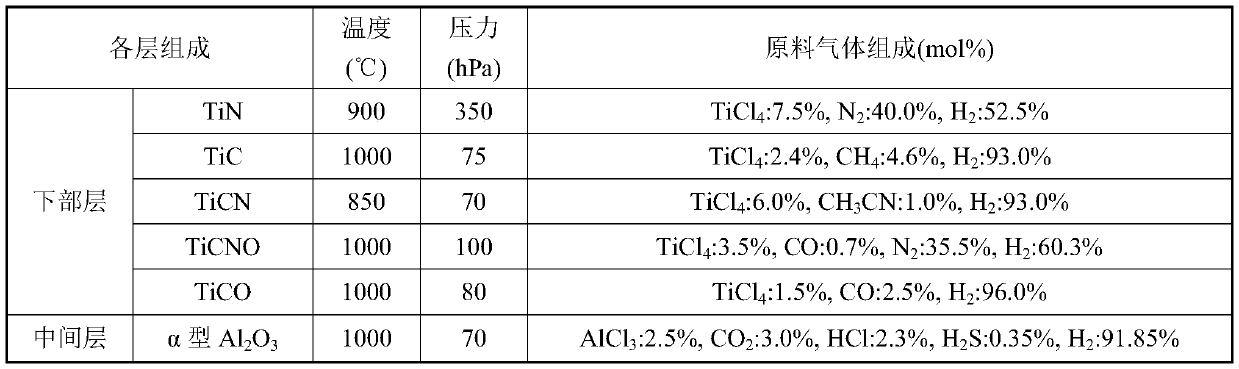

[0091] After cleaning the surface of the substrate, a coating layer is formed by a chemical vapor deposition method. First, the substrate is placed in an external thermal chemical vapor deposition apparatus, and under the conditions of the composition, temperature and pressure of the source gas shown in Table 1, the first layer, the second layer, and the third layer The order of and the average thickness shown in Table 2 form the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com